Home > About Us > Corporate Social Responsibility > Sustainability Report > Sustainability Report 2008 > 1. Environmental Activities & Performance (4)

1. Environmental Activities & Performance (4)

1. Environmental Activities & Performance (4)

| Lowering the Environmental Impact (Air, Water, Noise, Odors, Soil) |

| Realizing that its various production activities release substances that have significant environmental impact on the atmosphere and groundwater, the Kobe Steel Group undertakes periodic monitoring and implements a range of countermeasures to reduce its environmental impact. These include ongoing improvements to production processes, upgrading of facilities, installing more efficient, state-of-the-art equipment, and installing equipment to eliminate substances that are harmful to the environment. Group companies will continue in this effort to make their manufacturing activities more environment-friendly. (Emission data of production facilities is in the section entitled |

| Measures Combating Atmospheric Pollution |

| Plants and Works | |

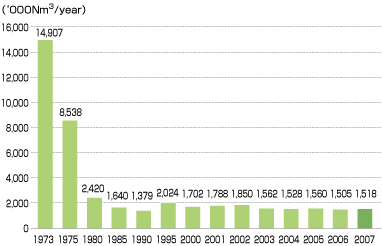

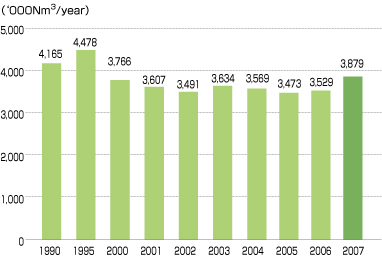

| Sulfur oxides (SOx) generated in production processes have been cut by reducing fuel consumption to save energy and using low sulfur fuels, as well as desulfurization treatment for emissions. At steel works, emissions have been reduced by using iron ore with low sulfur content, and natural gas for fuel, and by installing desulfurization equipment to clean gases emitted by coke ovens and boilers. Emissions of nitric oxides (NOx) are also being reduced with the introduction of low NOx fuel technology and measures to save energy. During fiscal 2007, efforts were continued to upgrade facilities and switch to low-sulfur fuels to combat atmospheric pollution. Measures were put in place to prevent any possibility of emissions deviating from standards by tightening operating controls when plants are in operation, and also more low-NOx burners and desulfurization equipment were installed. To control dust at the Kakogawa Works, dust-control nets have been installed, dust generating equipment sealed, and the capacity of dust collecting facilities increased. |

| Rates of Sulfur Oxide Emission | |

| Rates of Nitric Oxide Emission | |

*Data for 1990, 1995, 2000 are aggregates of Kakogawa and Kobe Works

| Environmental Activities in Group Companies | |

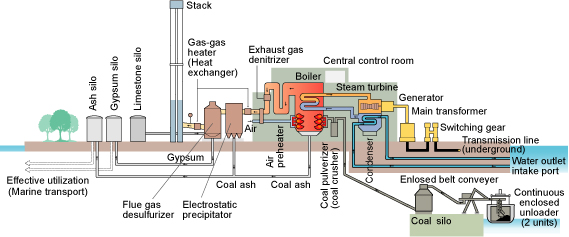

| Shinko Kobe Power Inc., with a generation capacity of 1.4 million kilowatts, operates an urban power station that coexists in harmony with the community. On this theme, tough environmental conservation measures are taken - including water quality conservation, noise, vibration, and offensive odor prevention, measures against wastes, and environmental harmony - by installing cutting-edge environmental analysis equipment and optimizing the environmental management system through ISO14001. For these environmental measures, about one third of the total construction cost of the power station (about 200 billion yen) was allocated. |

| Shinko Kobe Power Inc. | |

|

Continuous enclosed coal unloader By enclosing the unloader, dust is prevented from scattering. |

Coal silo and enclosed belt conveyor Coal silo and enclosed belt conveyorTwelve silos that can store 30,000 tons of coal per silo are installed. By enclosed the belt conveyor, the coal is completely enclosed from quay to boiler. |

| State-of-the-art Exhaust Treatment Equipment | |

Electric dust collector |

Exhaust denitration equipment |

Exhaust desulfurizer |

| Water Pollution Prevention |

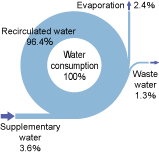

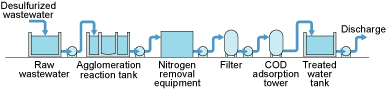

| In the Kobe Steel Group, the water consumption rate is being reduced by improving production processes and using recycled water. Water treatment for wastewater from production processes is managed by using systems best suited to the properties of the discharged water, and various other measures are undertaken to improve water quality. Finally, wastewater is purified through a treatment system to reduce the impact of water polluting substances such as COD (chemical oxygen demand) and SS (suspended solids) on public water supplies. For example, a water recycling system used at the steelworks purifies wastewater from the various production processes and other effluent through a treatment system that combines coagulating sedimentation, sand filtration, membrane treatment, and biological treatment, for reuse on site. At the Kakogawa Works about 96% of the water is recycled. At the Welding Company's Fujisawa Industrial Operations, facilities for the treatment of industrial wastewater (pressurized flotation method) have been expanded and treatment capacity doubled. Also, Shinko Kobe Power Inc. discharges wastewater after thorough cleaning at a comprehensive water treatment plant that provides not only coagulating sedimentation, filtration and neutralization, but also advanced wastewater treatments such as denitrification and COD absorption. Shinko Kobe Power also uses an eco-friendly water-intake/discharge system. |

|

|||||

| Comprehensive Wastewater Treatment System at Shinko Kobe Power Inc. | |

|

Activated sludge treatment facility |

| Noise Reduction |

| Measures to reduce noise from facilities is ongoing, based on surveys of the effects of plant noise on neighboring areas and information obtained from local residents. A diverse range of measures are undertaken to block or absorb noise, including enclosing noise-generating equipment such as fans, compressors and crushers in buildings, and installing soundproof walls and vibration-proof padding. Efforts are also made to limit noise generation by maintaining all machinery in good working order. |  Sound suppressing equipment for exhaust stack |

| Odor Reduction |

| Measures are taken to control odors generated at works and plants based on periodic monitoring and information obtained from local residents. |

| Preventing Ground Contamination |

| Ground contamination is prevented by strict observance of the Water Pollution Control Law and other regulations and by proper controls of hazardous materials at all plants and works. At times of land transactions and when required at plants or works, voluntary soil surveys are carried out in line with the Soil Contamination Control Law. If contamination should be identified through a voluntary survey, an immediate report is made to the government authorities and the necessary measures undertaken to decontaminate the ground. |