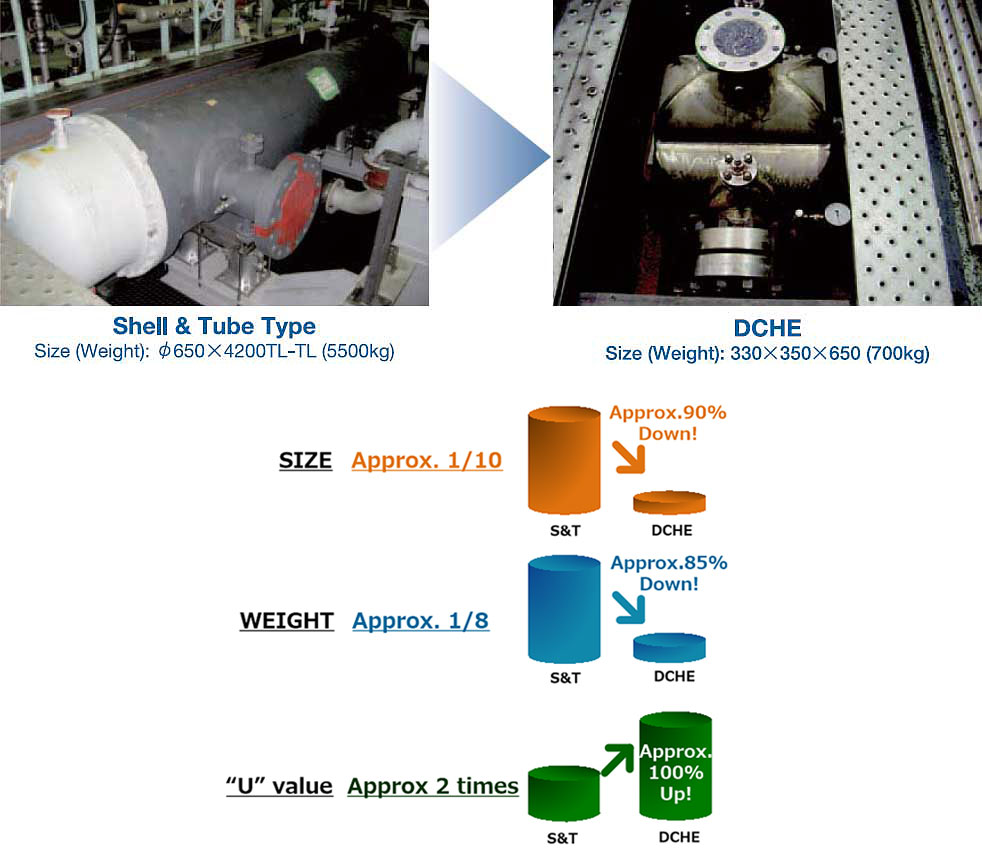

A multitubular heat exchanger for the nitrogen compressor was replaced with the DCHE. As a result, the DCHE could be made significantly more compact, approximately 10 % in volume and less than 15% in weight, compared with a multitubular heat exchanger of the same heat transfer performance and pressure loss. Also, the overall heat transfer coefficient increased to 200 %. This means that the energy efficiency is improved.

Comparing with Shell & Tube type HX

Feature of diffusion bonding

| Item | DCHE |

|---|---|

| Material | Stainless Steel |

| Applicable temp | <650°C |

| Applicable press | <100MPa |

| Fluid | Hydrocarbon, Cooling water and others |

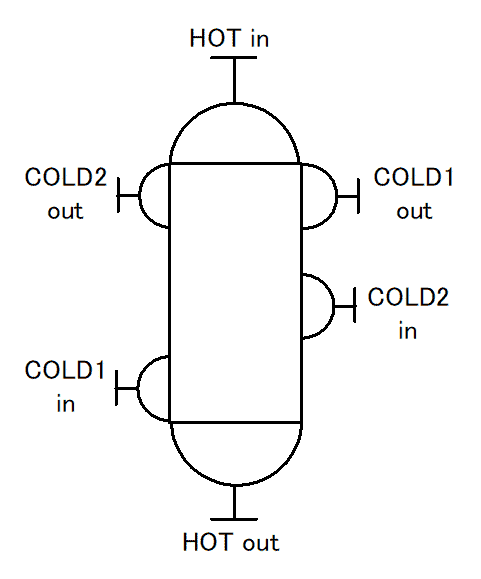

DCHE can be designed not only two stream but also multi stream. Stream number is normally limited by the availability of external space to mount headers. On the right drawing, this is the example for three streams type.

| DCHE | SHELL & TUBE | |

|---|---|---|

| Material | Stainless | Stainless steel, Titanium |

| Number of stream | Suitable for 2 or 3 (less than 6) | 2 |

| Fluid | Water and others | Sea water, water and others |

| Allowable temperature difference Hot & Cold (°C) | <200 °C | <200 °C |

| Desin temperature (°C) | -196 to 500 | -196 to 500 |

| Desin pressure (MPaG) | <100 | <50 |

| Capex (-) | 50 to 200 <100 (over 5 to 10 MPa) |

100 |

| Plot area (-) | 1 | 5 to 10 |

| Most suitable condition | High pressure, Cryogenic | Cryogenic |

The higher the design pressure goes, the bigger/larger the size of the S&T heat exchanger becomes. DCHE is more suitable for design pressure over 5 to 10 MPa in terms of foot print and cost.