Kobe steel has developed its own extra-high torque gear reducer in order to meet the ever-increasing demand for large polymer production capacity.

Our advanced LCM-EX extrusion technology may also be enhanced using our World renowned 'mixing' technology.

By use of variable clearance mixing segments the following benefits may be achieved when producing certain polymer grades;

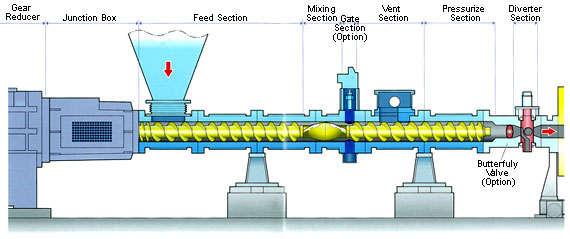

Adjustment of the circular clearance between the gate and the mixing segment by vertical movement of the gate allows control of the material filling ratio and residence time in the mixing barrel, making it possible to regulate the energy input to the material.

Vent port is used to remove residual monomer, peroxide and transformation products.

In case of large venting requirement, a long vent barrel or several vent barrels are equipped.

Figure of VCMT Mixing Section

VCMT Screw Segment

Gear Pump / Screen Changer

Mixing Screw

Vent Section