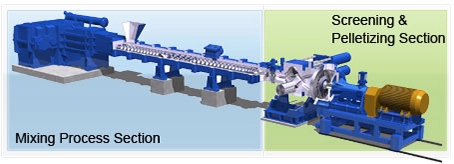

LCM-EX — Extrusion Pelletizing System

Features

Various clearance mixing technologies: VCMT (Patented)

Our advanced LCM-EX extrusion technology has been enhanced by combining it with the world renowned various clearance mixing technology (VCMT).

- High dispersion mixing

- Low-temperature mixing

- Energy saving

- High productivity

Gate Cotrol System (Optional)

The circular clearance between the gate and the mixing segment can be adjusted by vertical movement of the gate, allowing control of the material loading ratio and residence time in the mixing barrel, as well as control of input power for the material.

Contact Us

You can reach us by clicking the inquiry button.