The Kobe Steel Group carries out thorough and appropriate management of chemical substances, in line with domestic and international standards, and endeavors to reduce the use of hazardous substances and replace such substances with safer alternatives.

Kobe Steel has established the Kobe Steel Group Policy on Controlling Hazardous Chemical Substances and pursues thorough chemical substance management.

The use and management of each substance is clarified through Designated Chemical Substance Management Sheets. In addition to tallying the transfer and output of substances as required by the PRTR Law*1, we also engage in initiatives to limit the use and output of such substances.

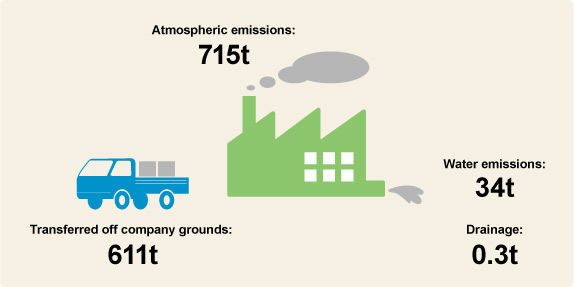

According to reported figures collected under the PRTR Law for each location in the Kobe Steel Group (in Japan), the Kobe Steel Group handled 52 substances, with a total output*2 of approximately 749 tons, and total transfer*3 of 611 tons.

Amount Discharged and Transferred at the Kobe Steel Group

*1 Law Concerning Pollutant Release and Transfer Register

*2 Amount discharged includes atmospheric and water emissions.

*3 Amount transferred includes transfers of substances off company grounds and drainage.

Both within and outside Japan, worldwide regulations on chemical substances are growing stronger. The Kobe Steel Group complies in an appropriate manner with these regulations.

We exchanged information and opinions on the CFC emissions law enacted in April 2015 and confirmed the current state of CFC management through environmental audits and other channels. As shown in the chart below, we pursue ongoing activities throughout the Group to further reduce chemical substance emissions.

Examples of Activities to Reduce Chemical Substance Emissions

| Company name | Location | Measures |

|---|---|---|

| Shinko Wire Company, Ltd. | Amagasaki, Hyogo Prefecture | Reused wire drawing lubricant |

| Daian Plant | Inabe, Mie Prefecture | Converted to less environmentally stressful chemicals to wash castings |

| Shinko Aluminum Wire Co., Ltd. | Sakai, Osaka Prefecture | Revised wash method, reduced wash oil used |

| Shinko-North Co., Ltd. | Kasumigaura, Ibaraki Prefecture | Switched to less environmentally stressful corrosion inhibitors |

| Kobelco Construction Machinery Co., Ltd. | Ogaki, Gifu Prefecture | Introduced dedicated device for painting Reduced flux used during painting |

| Japan Superconductor Technology, Inc. | Kitakyushu, Fukuoka Prefecture | Switched to less environmentally stressful cleaning agent |

Transformers, condensers and other used equipment containing PCB (polychlorinated biphenyl) are strictly stored, managed and reported, as prescribed under the Act on Special Measures Concerning Promotion of Proper Treatment of PCB Wastes.

We comply thoroughly with witnessed rules when contracting for outside disposal of PCB electronics and through internal audits of related management conditions. We also have measures in place to ensure final disposal within the period prescribed by law.