The two rotors have a construction whereby they are supported at both ends with bearings to enable high-speed operation in a very stable condition. The both-ends supported design eliminates the possibility of metal contact between the rotors, and between the rotors and the chamber. Moreover, to withstand the high pressure generated by the mixing action, the mixing section has a special triangular shape to optimize strength and mixing performance.

A highly powerful gear reducer has been developed to meet the ever-increasing demand for larger polymer production capacity.

The drive end dust stops and water end visco seals are designed to prevent powder and molten polymer leakage and to make maintenance quicker and easier.

Drive End Section

Mixing Rotor

Gate Section

(Patented)

The diameter of the feed screws is larger than that of the mixing section, making it easier to convey low bulk density materials and eliminate feed-neck problems. In addition, the counter-rotating screws are excellent in homogeneously blending materials that are fed separately.

The cross-sections of the rotors in the mixing section have a special triangular shape, providing tip clearance between the rotors and the chamber wall at six points. In addition, the mixing wings have axially continuous rotor tips, allowing the polymer to repeatedly pass through the tip clearances. It is this repeated passing of the polymer through the tip clearances that provides the high shear strain necessary for effective melting and thorough mixing. Hence, Kobe Steel's rich design experience makes it possible to select the rotor shape most appropriate for melt homogenization and additive dispersion.

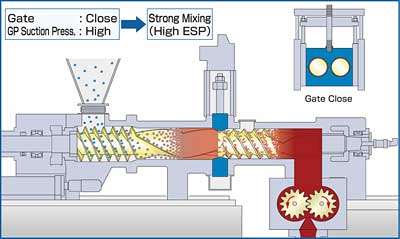

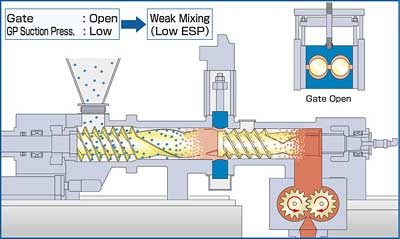

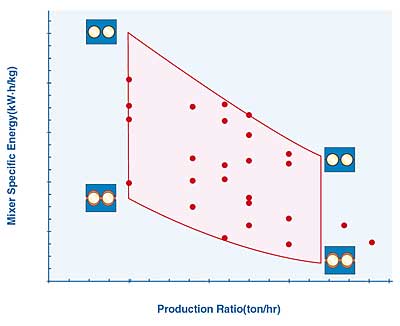

Adjustment of the circular clearance between the gate and the rotors by vertical movement of the gate allows control of the material filling ratio and residence time in the mixing chamber, making it possible to easily regulate the energy input to the material. This structure enables easy control over a wide range of mixing conditions and over a wide range of resin temperature.

![Gear Pump (KNT150 [1,600 kW] )](/english/products/resin/lcm/lcm/img/P04-01.jpg)

Gear Pump

(KNT150)

Dual Type Screen Changer

(KSD425C)

Under Water Pelletizer

(UP850N)