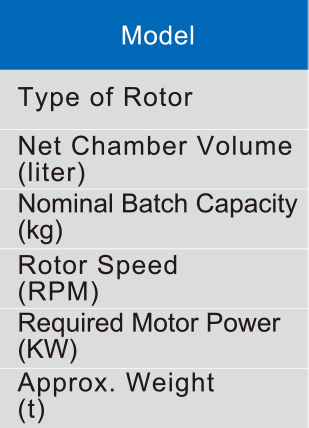

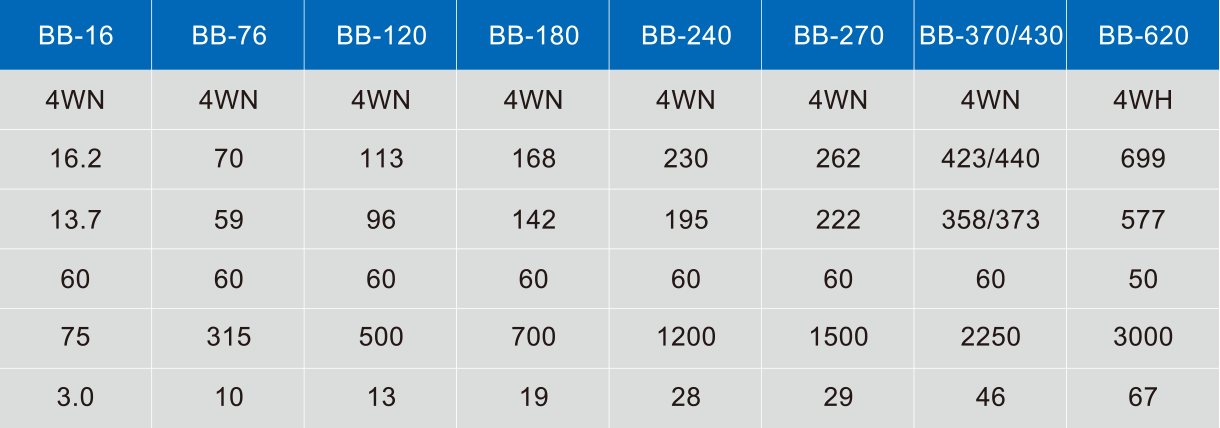

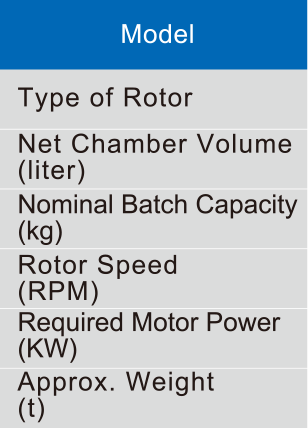

KOBELCO high-performance mixing technology reduces batch times with improved compound quality. Our patented mixer innovations drive greater output and batch uniformity with lower energy consumption. Our Internal Intensive mixers are available in a wide range of chamber volumes from a minimum 1.6 liter laboratory size to a maximum 699 liter production size.

|

|

|---|

|

|

|---|

|

|

|---|

|

|

|---|

The Kobelco BB-270IM and BB-430IM intermeshing mixers will replace 270 and 370 (or 430) tangential mixers keeping the existing gear reducer (even speed) and the main motor. Contact us for details.

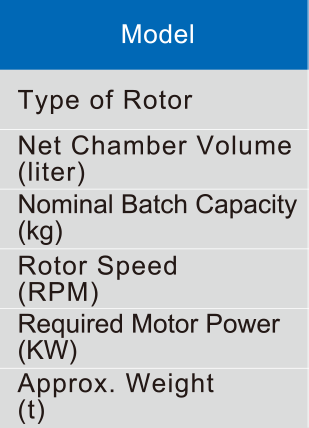

Remarks:

- 1. Rotor type 4WN stands for 4-wing N type and 4WH stands for 4-wing H type. Other types of KOBELCO rotors are available. Contact us for details.

- 2. Specific gravity of compound is 1.1 in the table. Fill factor of 4WN is 77%, 4WH is 75%, KIR-Ⅱ is 65%.

- 3. Fill factor and mixing capacity are subject to change on mix condition, compound, types of drop door and weight, etc.

- 4. Each of weight data of lab machine (BB-L1800, BB-L4200, BB-L1600IM and BB-L3200IM) includes main body, gear reducer, main motor and panel but excluding hydraulic unit. Each of weight data of production machine includes main body and gear reducer but excluding hydraulic unit, lubrication unit, panel and main motor.

- 5. The technical data mentioned here are for reference.

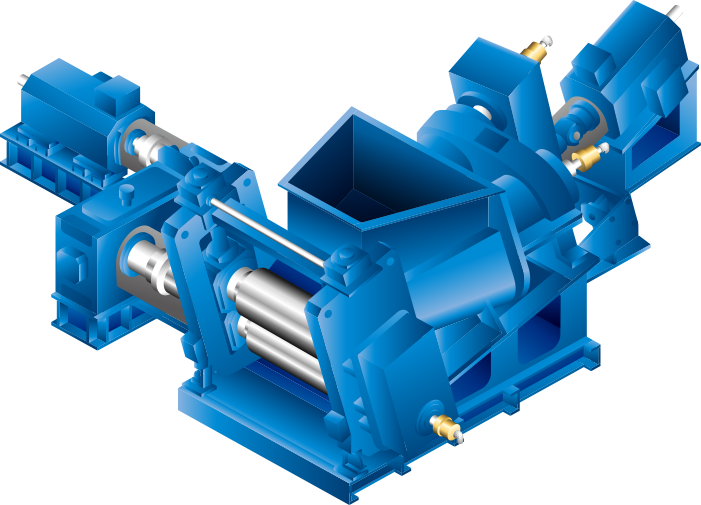

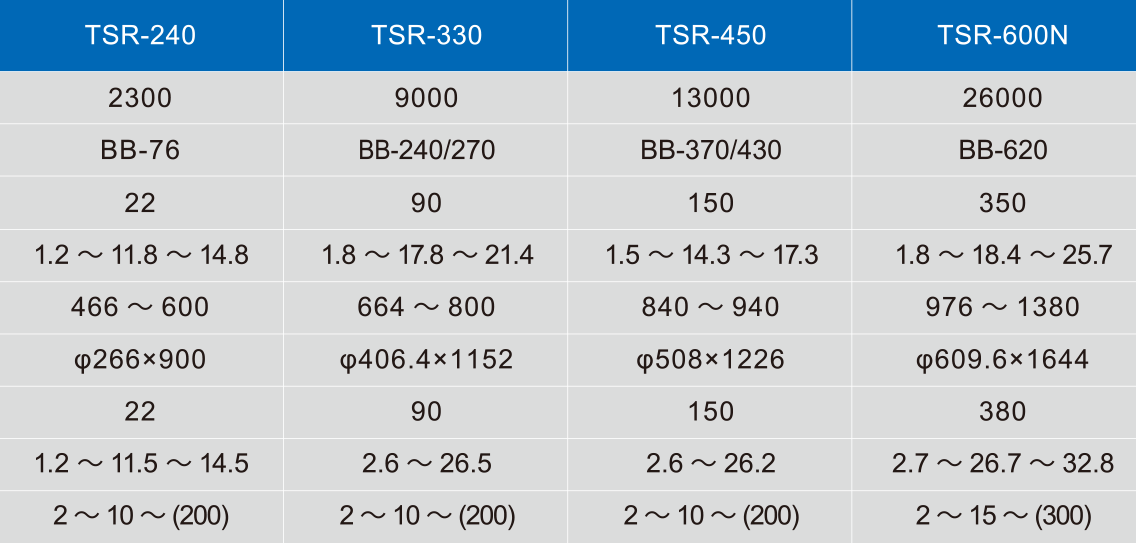

The KOBELCO Twin Screw Roller Head Extruder (TSR) is a specialized twin screw extruder with an inclined roller-head or “sheet forming die”. The machine is designed to accept material discharged from an internal intensive mixer and then form a continuous, seamless material sheet. The TSR is ideal for applications such as tire manufacturing, custom compounding, hose & belt and industrial rubber goods.

|

|

|---|

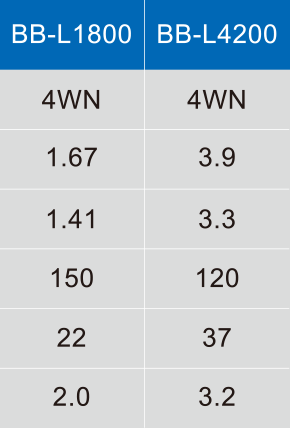

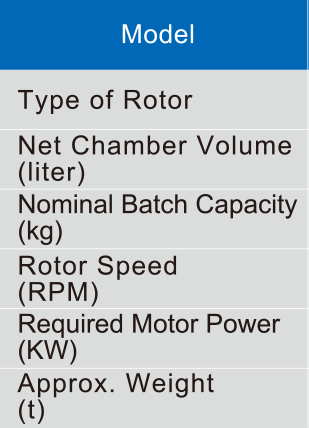

Remarks:

- The technical data mentioned here are for reference.