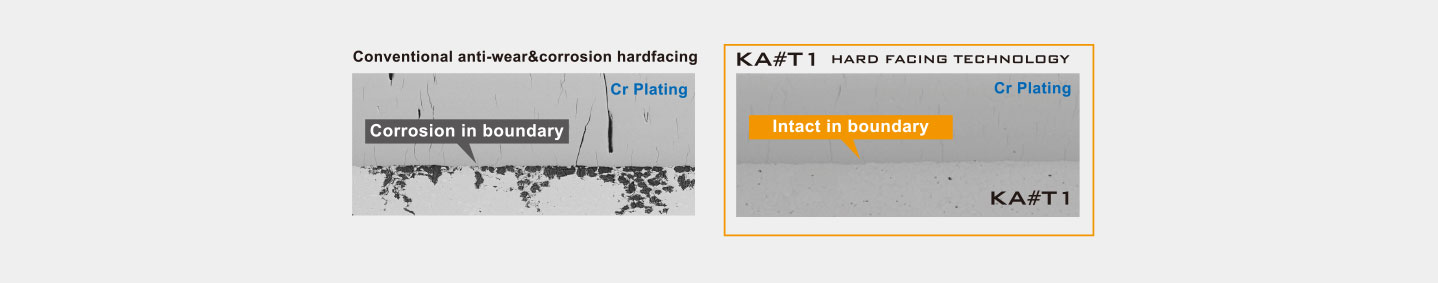

The materials and additives used in silica mixing in the tire industry, and the associated reaction by-products, have increased the requirements for the mixer chamber and rotors to be anti-corrosive. At the same time, as the filler (silica) content of these new compounds increases, so too does the need to have an anti-abrasive surfacing material.

The mixing chamber must have anti-corrosion and anti-abrasion characteristics to satisfy these conflicting requirements.

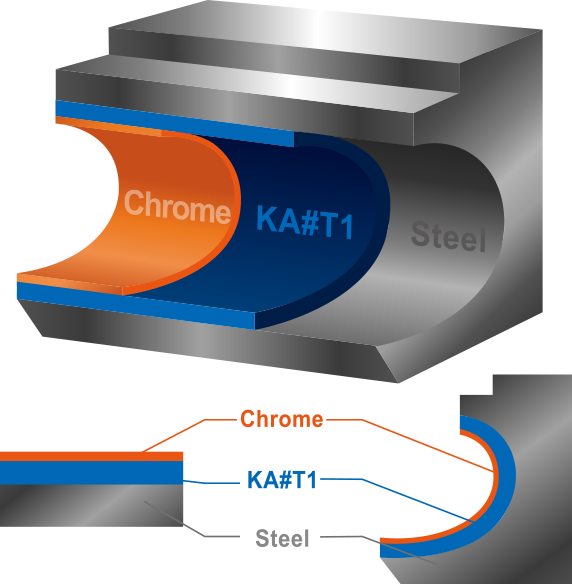

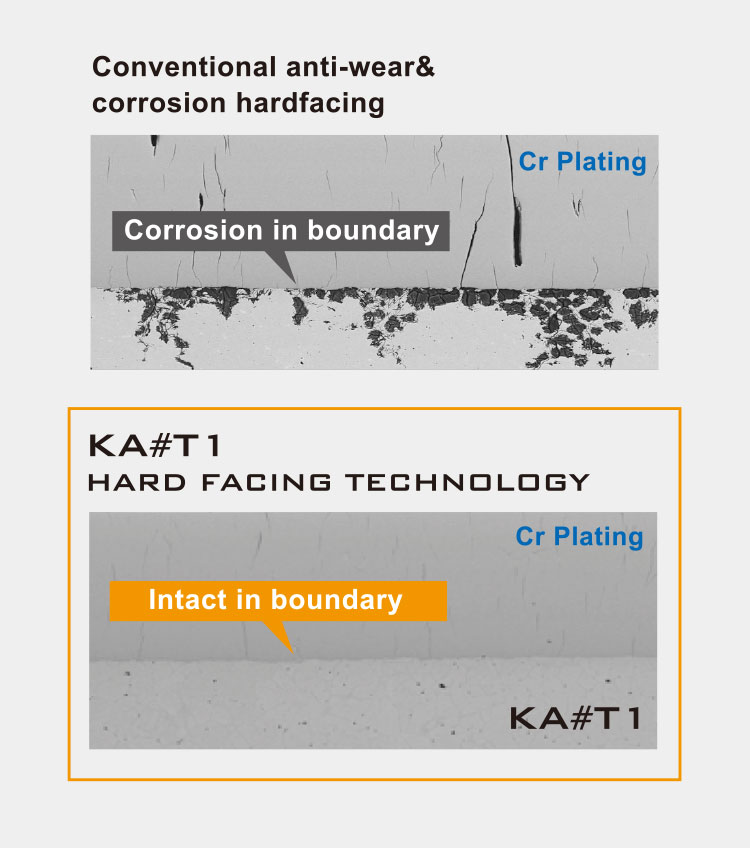

KA#T1 has been developed to have high and balanced anti-wear and anti-corrosion performance for the mixing chamber for silica masterbatch mixing. It also has a good bonding strength with chrome plating, which provides stable tip clearance before becoming worn. KA#T1 and Cr plating provides the optimum conditions for longer stable mixing (productivity and quality) compared with hard surfacing alone. KOBELCO has delivered this solution on approximately 80 mixers since 2011.

KA#93 has high anti-corrosion performance and is applied to Kobelco’s rotors. It has an improvement in anticorrosion over the conventional KA#104 while also having improved anti-abrasion performance over the traditional hard facing material used on rotors.

Again, KA#93 has good bonding strength with Cr plating, providing extended life. In addition, KOBELCO also offers a range of other materials that can meet application processing needs and address specific wear and/or corrosion concerns.

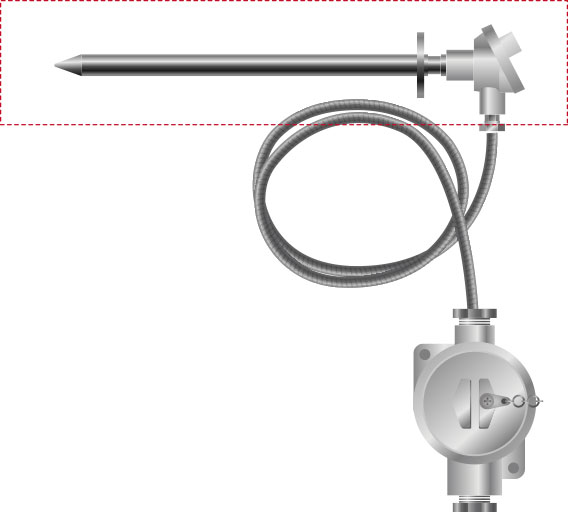

Maintaining compound temperature at a fixed level is applied in silica mixing to improve the coupling agent reaction. This is achieved by controlling the rotor speed through a feedback loop from the batch thermocouple. Kobelco has developed a new high responsive thermocouple. Compared to the standard one, it is possible to measure temperatures closer to actual mixing temperature, and its lifetime has improved by a special hardfacing KA#53.

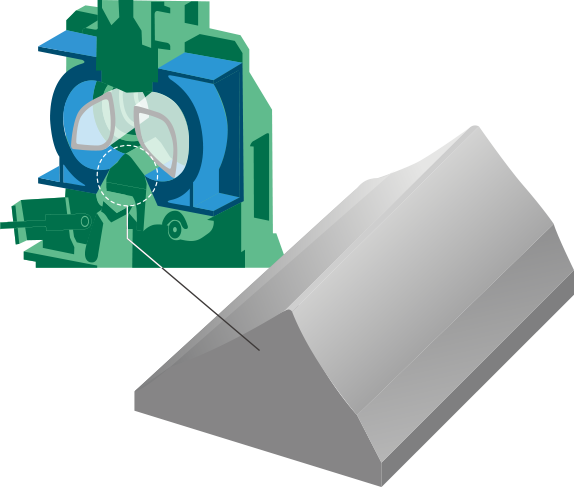

New tread compounds are designed to improve the balance grip, energy efficiency and anti-wear characteristics of the tire. Materials to improve rubber-to-metal adhesion are used to reduce the tire weight, and these additives can cause problems by increasing the amount of compound that sticks internally on the drop door. The ‘spade door top’ has been developed specifically for these adhesive compounds to avoid material hang-up while improving compound flow around the door.

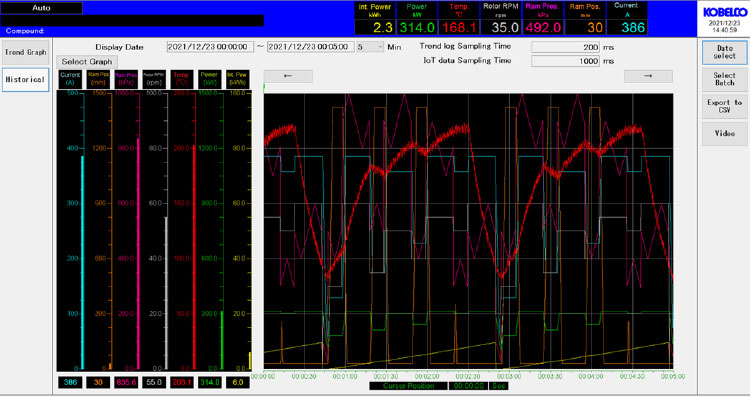

KOBELCO BBMC (BB-Mixer Monitor & Controller) has various functions to support mixing operations such as manual operation, data logging, automatic operation, IoT function and maintenance function.

These functions achieve not only controlling the quality of various kinds of mixing efficiently, but also provide records of mixer status and information for the maintenance.