Home > Products > Energy & Chemical Field > LNG Vaporizers > Kobe Steel's intermediate fluid vaporizers used in floating LNG receiving terminal in Italy

Kobe Steel's intermediate fluid vaporizers used in floating LNG receiving terminal in Italy

Kobe Steel's intermediate fluid vaporizers used in floating LNG receiving terminal in Italy

“FSRU Toscana”: the world's first LNG storage & regasification unit installed on a ship that is permanently moored in the open sea

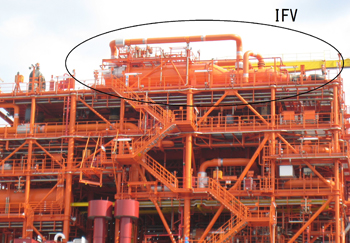

Kobe Steel's intermediate fluid LNG vaporizer (IFV) on “FSRU Toscana”

On December 20, 2013, a floating storage and regasification unit (FSRU) started commercial operation in Italy. Kobe Steel, Ltd. supplied three intermediate fluid LNG vaporizers (IFVs) for use on the FSRU.

The FSRU is essentially an LNG receiving terminal installed on a floating vessel. The unit is moored 12 nautical miles (22 kilometers) off the coast of Tuscany, where the water depth is 120 meters. The FSRU receives liquefied natural gas (LNG) from gas carriers, stores it on board, and then regasifies the LNG. The gas is then sent via an underwater pipeline to the mainland and connected to the national grid.

The FSRU was converted from a former gas carrier, the Golan Frost, and is now called “FSRU Toscana". Conversion work was conducted by EPC contractor Saipem S.p.A. for OLT Offshore LNG Toscana S.p.A., the owner and operator of FSRU Toscana.

Kobe Steel supplied three IFVs to Saipem. Each IFV has a regasification capacity of 150 tons per hour. Seawater is used as the heating medium to vaporize the LNG.

Commissioning of the FSRU began in September 2013 and the IFVs performed as designed. Following the start of commercial operation in late December, the FRSU has been in successful operation. This is the world's first regasification unit installed on a ship that is permanently moored in the open sea.

Advantages of floating storage and regasification units

![]()

FRSUs are often converted LNG carriers with vaporizers and other equipment installed on board. Moored offshore, FSRUs serve the same function as LNG receiving terminals on land. In comparison to onshore receiving terminals, FSRUs are noted for the following features:

- Using converted LNG carriers reduces construction costs and construction time, as FSRUs do not require land preparation and tank construction, which are necessary for land-based receiving terminals.

- As FSRUs are situated on the ocean away from habitats, environmental regulations are fewer and construction permits are relatively easier to obtain.

- FSRUs can be easily moved. They can be used temporarily until a receiving terminal on land is constructed or to meet seasonal peak demand.

Due to these features, the demand for FSRUs is anticipated to rise especially in Asian countries where LNG demand is rapidly increasing.

Intermediate fluid vaporizers on vessels

![]()

For the installation of vaporizers on a ship, it is necessary to deal with ship rolling and pitching on the ocean. Open rack vaporizers (ORVs) are the most common variety of vaporizers used in onshore receiving terminals, but are unable to cope with the rolling and pitching movement of ships. As a result, a different type of vaporizer is required for FSRUs.

From the preliminary stages of this project, Kobe Steel worked in cooperation with OLT and Saipem on evaluating LNG vaporizers suitable for FRSUs. Detailed simulations and analyses of ship motion were carried out and led to the adoption of Kobe Steel's IFV in the project. IFVs are generally used on land, but for this project, Kobe Steel made modifications so that they could be used at sea.

“During commissioning, which began in September last year, our IFVs achieved stable performance, even under rolling and pitching conditions, and successfully completed all performance tests for commercial start-up of the FSRU in December. Ever since, our IFVs have continued to run smoothly," said Kobe Steel.

“As one of the leading suppliers of LNG vaporizers, we have supplied ORVs and IFVs mainly to onshore LNG regasification terminals. Based on our success with the FSRU Toscana, we are committed to providing the best solutions to FSRU projects, as well as conventional onshore terminals," said Kobe Steel.

Kobe Steel is one of the world's leading manufacturers of LNG vaporizers. Since 1977, Kobe Steel has delivered over 150 ORVs and since 1980, over 30 IFVs to Asia, Europe, and Central and South America.