Home > Products > Energy & Chemical Field > LNG Vaporizers > IFV (Intermediate Fluid Vaporizer)

IFV (Intermediate Fluid Vaporizer)

IFV (Intermediate Fluid Vaporizer)

The Intermediate Fluid Vaporizer (IFV) was originally developed by Osaka Gas Co., Ltd. and licensed to us about 30 years ago. Since then, Kobe Steel has delivered more than 30 units of IFV.

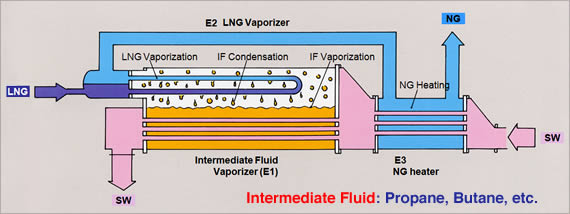

The IFV is characterized by its unique concept of three heat exchangers and the use of intermediate fluid. Thanks to the use of intermediate fluid, the IFV is not subject to freezing and has a wider temperature range of the heating medium.

Process Flow

![]()

The IFV consists of the below three sections:

E1: Intermediate Fluid Vaporizer

E1: Intermediate Fluid Vaporizer - Intermediate fluid (shell side) is vaporized by seawater (tube side).

E2: LNG Vaporizer

E2: LNG Vaporizer - LNG (tube side) is vaporized by the heat from the condensation of the intermediate fluid (shell side). Intermediate fluid is condensed by LNG on the surface of the tubes and dropped to the bottom of the shell.

E3: NG heater

E3: NG heater - LNG (shell side) is heated by seawater (tube side) up to an ambient temperature.

Main Application of IFV

![]()

LNG vaporizers, especially

for FSRU (Floating Storage & Regasification Unit)

for FSRU (Floating Storage & Regasification Unit)  with Cold Power Generation System

with Cold Power Generation System  for Seawater with High Content of Suspended Solid (SS)

for Seawater with High Content of Suspended Solid (SS)

Erosion/corrosion-resistant Titanium Tubes are used for Seawater with High Flow Velocity

for Seawater with High Flow Velocity  with Circulation System of Heating Medium in Closed-loop

with Circulation System of Heating Medium in Closed-loop  for Utilization of Cold Energy, such as

for Utilization of Cold Energy, such as

Cold Power Generation System (with Propane Rankin Cycle, Direct Expansion of Natural Gas, etc.)

Cold Power Generation System (with Propane Rankin Cycle, Direct Expansion of Natural Gas, etc.)  Intake Air Cooling for Gas Turbine to increase Power Output

Intake Air Cooling for Gas Turbine to increase Power Output

Brochure Download

Please complete the questionaire to download the brochure.

LNG Vaporizers on FSRU: Intermediate Fluid Vaporizer

LNG Vaporizers on FSRU: Intermediate Fluid Vaporizer- Complete the questionaire

![]()