Following the design concept of the HYPER series, noted for high endurance, low noise performance and compactness, the MX type gear reducer achieves high torque and a screw speed of more than 1,000 rpm.

Further, by adding high thrust performance, the technology allows wider range of operation and realizes downsizing of the HYPERKTX.

As for screw shafts, the manufacturing method of the base material and structure of the coupling portion has been improved to allow extra high torque.

Since specifications of involute spline for screws are equivalent to the conventional HYPER series, screw elements are interchangeable.

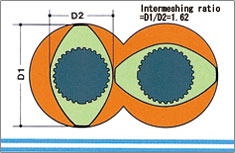

The ultra deep channel screws (screw intermeshing ratio = 1.62, highest level in the world) are applied to increase material conveying capacity and preventing local heat generation.

Ultra deep channel full flight screw

Screw intermeshing ratio D1/D2=1.62

Relation between screw intermeshing ratio and full volume ratio

As represented by Kobe Steel's unique VCMT Rotor Segments(pat.) and Rotor Segments(pat.), a variety of screw segments is available to meet the wide range of customer's requirements. The optimum screw design promises the best performance.

Super Alloy screws are available to provide excellent corrosion resistance and wear resistance.

In addition to standard barrels, we have long vent barrels and side vent barrels for high degassing applications and gate equipped barrels for controlling mixing intensity. The barrels are designed to realize high heating and cooling efficiency.

The Super Alloy barrels with high corrosion resistance and wear resistance are available.

Strand dies are designed to minimize pressure loss to enable high extruding capacity and to produce strands under stable conditions. In addition to the strand dies, various types of dies such as hot cut pelletizer dies, sheet dies and film dies are available.

All the models are equipped with Overload Protector set between electric motor and a gear reducer as standard.

This safety device has high reliability because of its mechanical shutdown system and can be easily restored in a normal conditions.

HYPERKTX30 and HYPERKTX46, of which barrels are frequently changed for the purpose of research and development, are equipped with a quick barrel changer leading to as a standard specification to enable barrel changes in a short time.

Since the barrels are mounted on the lower tie rods, they can be easily changed only by disconnecting their piping and wiring.

Quick barrel changer

Screw elements and shafts of involute spline type have a unique mechanism for smooth assembling.

The die head can be easily opened or closed by manual C-clamps to Reduce the time required for changing screens or screws.

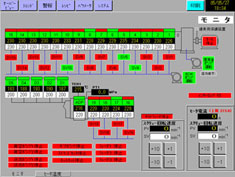

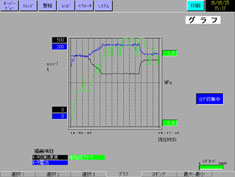

The KTX-FA is an operation control and monitoring system developed by Kobe Steel for exclusive use for the HYPERKTX. Tuning-ups of the operation parameter, recipe management, and maintenance management can be totally performed on the color LCD.

KTX-FAⅢ overview screen

KTX-FAⅢ trend screen

KTX-FAⅢ self-stand type installed close to the machine

KTX-FAⅢ built-in type operation panel

We can select and supply the most suitable auxiliary equipment for the customer.

Gear pump/Screen changer/Underwater hot cut pelletizer

Dual type screen changer

Underwater pelletizer

Hot cut pelletizer (water cooling)

Hot cut pelletizer (air cooling)

Side feed compactor

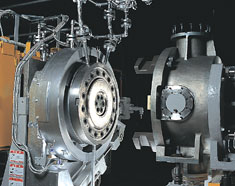

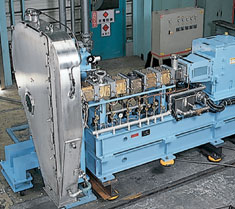

The Technical Center at Kobe Steel is equipped with mixing and extruding machines for plastics and rubber and various types of auxiliary equipment including feeders, pelletizers and measuring instruments to meet the customer's requests for testing including performance check before purchasing or supporting the development of new materials.

Technical Center

HYPERKTX testing equipment