Super Alloy is applied to screws and barrels of the HYPERKTX as a corrosion and wear resistant material developed by Kobe Steel by combining metal processing technology, such as casting, forging and machining, owned by the company.

We can provide the most suitable material according to the customer's application.

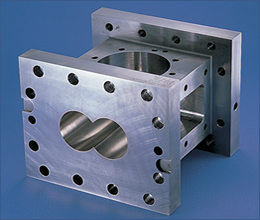

Super Alloy barrel SAB-1

SAB-1 lining layer

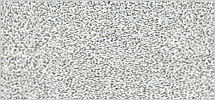

SAB-1 microstructure (x400)

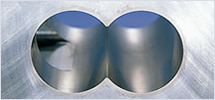

Super Alloy barrel SAB-HS

SAB-HS/HIP lining layer

SAB-HT/HIP microstructure (x400)

| Super Alloy |

Manufacturing method |

Composition | Hardness (HRC) |

Wear resistance |

Corrosion resistance |

Application |

|---|---|---|---|---|---|---|

| SAB-1 | Special melt bonding |

Ni-base high alloy |

57-62 |

◯ |

◯ | Standard material of Kobe Steel with fairy high wear resistance and corrosion resistance that can be used for wide range of application. |

| SAB-11 | Special melt bonding | Ni-base high alloy |

58-63 | ◎ | ◯ | Filler compounding such as talc, CaCo3, flame retardant and pigment. |

| SAB-LC | Liner | High Cr alloy |

55-60 | ◎ | ◯ | Compound with highly abrasive filler such as Fe2O3, TiO2 and glass fiber. |

| SAB-HT | HIP | Ni-base high alloy |

57-62 | ◎ | ◯ | Compound with highly abrasive filler such as Fe2O3, TiO2 and glass fiber. |

| SAB-HS | HIP | Ni-base high alloy |

50-55 | ◯ | ◎ | Highly corrosive materials such as flourine type plastics and rubber. |

| Super Alloy |

Manufacturing method |

Composition | Hardness (HRC) |

Wear resistance |

Corrosion resistance |

Application |

|---|---|---|---|---|---|---|

| SAS-1 | Special melt bonding

|

Stainless type high alloy |

57-62 | ◯ |

◯ | Standard material of Kobe Steel with fairy high wear resistance and corrosion resistance that can be used for wide range of application. |

| SAS-2 | Special melt bonding | Co-base high alloy |

57-62 | ◯ | ◎ | Clean grade materials such as PC, and high viscosity elastomer. |

| SAS-H1 | HIP | Fe-base high alloy |

60-62 | ◎ | ◯ | Filler compounding such as talc,CaCo3, flame retardant and pigment. |

| SAS-HT | HIP | Ni-base high alloy | 57-62 | ◎ | ◯ | Compound with highly abrasive filler such as Fe2O3, TiO2 and glass fiber. |

| SAS-HS | HIP | Ni-base high alloy | 50-55 | ◯ | ◎ | Highly corrosive materials such as flourine type plastics and rubber. |

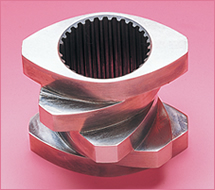

Super Alloy screw elements SAS-HS

SAS-HS/HIP bimetallic kneading disk

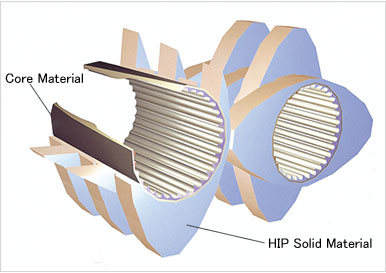

Screw element of SAS-HT, HS and H1 has bimetallic structure to transmit high torque

Kobe Steel has comprehensive HIP technology consisting of HIP equipment, Development and production of HIP lining materials, and Matching of HIP materials. This composite technology is applied to the development of HIP barrels and screws made of HYPERKTX Super Alloy.

HIP equipment

Dry sand/rubber wheel abration test

Formic acid (10%), 20°C×24hr

Acrylic acid (20%), 100°C×5hr

Fluoric acid (10%), 20°C×1hr