HYPERKTX achieves a high productivity with VCMT(Various Clearance Mixing Technology) Rotor Segments, which are more suitable for high-speed, high-torque Twin Screw Extruders, in addition to the conventional Kneading Disk for distribution mixing and Rotor Segments characterized by Kobe Steels outstanding polymer mixing technology.

Kneading Disks

Rotor Segment

VCMT Rotor Segment

Mixing action of Kneading Disk

Mixing action of Rotor Segment

Mixing action of VCMT Rotor Segment

The Kneading Disk is a combination of several disks having a cross-section of double flight screws. The clearance between the tip and barrel is very small.

Material mixing using the Kneading Disk is a kind of distribution mixing and performed by dividing the materials with discontinuous disks. The amount of materials passing through the clearance between the disk tip and barrel inner wall is very small because the clearance is very small.

The Rotor Segment is equipped with three special continuous wings having a large clearance (tip clearance:TC) between the rotor tip and barrel inner wall.

Large tip clearance, where shear stress is produced, and the continuous wings of the Rotor Segment allows all the materials to pass through the clearance repeatedly. This action achieves homogeneous dispersion mixing.

In addition, the Rotor Segment, having a large tip clearance, can avoid local heat generation. As a low mixing temperature is achieved, material stress is reduced and a high quality extrusion is possible. Furthermore, low-temperature mixing does not require much energy. As a result, operation under a wide range of conditions is possible, leading to improved productivity.

Comparison of shea strss at Rotor Segment and Kneeding Disk

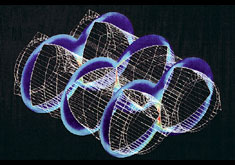

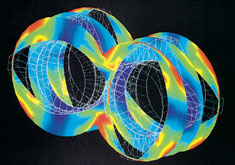

The VCMT Rotor Segment has two continuous wings, with small TC and large TC alternating along the shaft and revolution direction. The VCMT Rotor Segment is characterized by the size of TC and the number of partitions per one segment, as well as various twisted angles against the shaft's direction of the mixing wings.

The large TC of the VCMT Rotor Segment enables hard materials just starting to melt to pass the TC easily. It promotes a large amount of materials to pass through the TC, the plasticization of the material, and more homogeneous shear stress. Also the large TC can keep the mixing temperature low by avoiding local heat generation.

On the other hand, the small TC promotes heat transmission to barrels by scraping materials stuck on the wall inside barrels and prevents the accumulation of materials as well as produces strong shear stress. The two-wing rotor shape excels in forwarding materials. Production can be increased without a feeding neck by forwarding the air and water brought in with a filler as well as mixing the filler into a polymer and forwarding materials. The air and water is effectively discharged through the back vent.

The VCMT Rotor Segment can keep the temperature of the mixing material low even at high speed operation.

Heat generation around Rotor Segments

Heat generation around Kneading Disks

By integrating the VCMT Rotor Segment and other screw elements, the best mixing performance can be achieved.

Comparison of capasity ability of the Filler compounding (PP/Talc15%)