Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2011 > Material Balance

Material Balance

Material Balance

| Quantifying resource and energy consumption at every stage of the production process Striving to use materials more efficiently and recycle byproducts |

The Kobe Steel Group is extending its environmental management to take account of the environment in all its diverse business activities. Improving energy efficiency and turning byproducts into recycled resources are ongoing activities that form part of this.

Utilization of Raw Materials and Energy at Kobe Steel

Iron & Steel Business

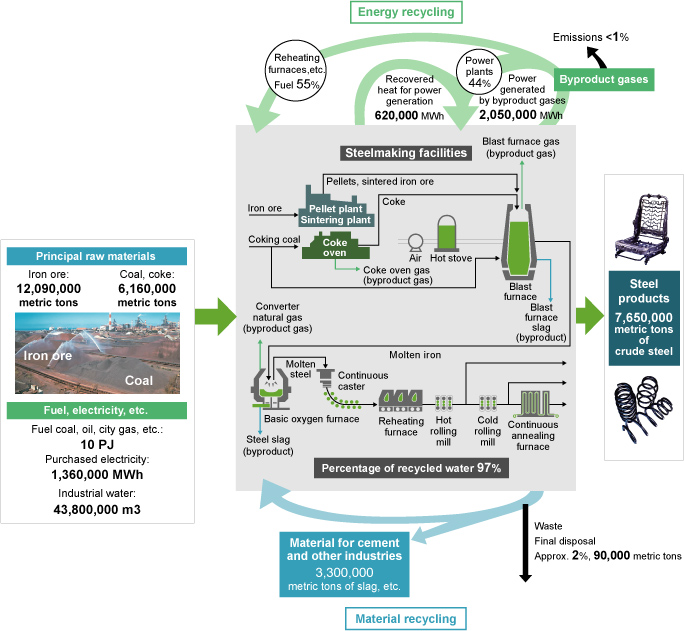

Our Iron & Steel Business accounts for 95% of all energy used at Kobe Steel.In fiscal 2010, we consumed 12.09 million metric tons of iron ore, 6.16 million metric tons of coke and coking coal, 10 PJ of fuels such as coal, oil and city gas, and 1.36 million MWh of electricity. We take almost all of the byproduct gases generated by different stages of the production process, such as coke oven gas, blast furnace gas, and converter gas, and effectively reuse them as fuel for the reheating furnaces at the rolling mills and the in-house power generation plants. We also actively reuse recovered waste heat to generate electricity. As a result of these efforts, over 50% of the electricity used in the production process is generated by byproduct gases and waste-heat recovery.

We also recycle 98% of the other byproducts of the productionprocess, such as slag, dust and sludge, as raw material for cement, paving material, and other applications.

We remain committed to improving the efficiency of our raw material and energy use, and we will continue developing technologies that enable us to manufacture our products while preserving the environment.

Use of Raw Materials and Energy by the Iron & Steel Business in Fiscal 2010

Welding Business

The Welding Business produces welding wires and welding electrodes using steel wire rods and hoops, flux and liquid glass as raw materials. In fiscal 2010, at our three plants in Fujisawa, Ibaraki, and Saijo we used a total of 130,000 metric tons of raw materials, 40,000 MWh of electricity, and 53 TJ of city gas for energy. We manufactured 130,000 metric tons of products. As a consequence, 3,000 metric tons of byproduct were generated, of which 84% was recycled.

Raw Material and Energy Use by the Welding Business in Fiscal 2010

|

|

Aluminum & Copper Business

The Aluminum & Copper Business uses aluminum and copper ingots, scrap metal and other materials for the production of a wide range of aluminum and copper products. In fiscal 2010, we used 390,000 metric tons of raw materials, 480,000 MWh of electricity, and 3.8 PJ of city gas as energy to produce 360,000 metric tons of products.

Despite producing 26,000 metric tons of waste, including slag and dust from melting and casting and waste sludge, we managed to recycle 95% of that total.

Raw Material and Energy Use by the Aluminum & Copper Business in fiscal 2010

|

|