Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2011 > Social Contribution Activities Technical Support Project to Restore Blast Furnace at Huachipato Steelworks

On February 27, 2010, Chile was hit by a massive 8.8 magnitude earthquake.

The Huachipato Steelworks operated by Compania Siderurgica Huachipato S.A. (CSH), the only blast furnace steelmaker in Chile, was badly damaged.

CSH's parent company Compania de Acero del Pacifico S.A. (CSH), which is also one of our iron ore suppliers, came to us and asked for technical support in restoring the works, given Kobe Steel's experience in the Great Hanshin-Awaji Earthquake in 1995.

The following report looks at the human and technical drama that unfolded through the eyes of the Kobe Steel Group.

Returning the Favor after the Great Hanshin-Awaji Earthquake:

The Men of Steel who Rose to the Challenge

Iron ore is the raw material that is melted to create iron. Blast furnaces combine various different technologies and represent the core facility at any steelworks. To get Chile's only blast furnace up and running as quickly as possible, CAP called on Kobe Steel for technical support, based on our experience in restoring blast furnace operation after the Great Hanshin-Awaji Earthquake.

At the time of the Great Hanshin-Awaji Earthquake, the Kobe Steel Group received a great deal of support from all over the world. We wanted to return the favor and provide the technology needed to restore the blast furnace in Chile. We therefore decided to send over three engineers who worked on restoring our own blast furnace at the Kobe Works.

The three engineers sent over to Chile shake hands in front of a salamander (solidified iron) removed from the blast furnace at the Kobe Works

From left: Yoshio Kita (then Civil Construction Technology Department, Iron & Steel Business), Yoshiyuki Matsui (then Technology Administration Department, Iron & Steel Business) and Masaaki Takeuchi (then Machine Technology Department, Shinko Engineering & Maintenance Co., Ltd.)

A 24-hour Framework Linking Japan and Chile

"Now it's our turn to return the favor." That's what blast furnace specialist Yoshiyuki Matsui, one of the chosen engineers, had in mind. Photos from the scene of the earthquake were provided courtesy of Mitsubishi Corporation, which has capital ties with CAP. They showed scenes that were very similar to those at the Kobe Works after the Great Hanshin-Awaji Earthquake. Equipment specialist Masaaki Takeuchi and construction specialist Yoshio Kita were selected as the other two engineers to go over to Chile, with Shinji Kitano, General Manager of the Ironmaking Department at the Kobe Works, coordinating the project from Japan.

They continued to receive updates from the scene via Mitsubishi Corporation, enabling response measures to be meticulously planned out before the three engineers set off for Chile. The contents of onsite meetings were also relayed back to Kobe Steel that same day, creating a 24-hour real-time support framework. This marked the start of a technical support project on the other side of the world.

The top of the Huachipato blast furnace after being damaged by the earthquake

Second Best: Getting Operations Up and Running as Quickly as Possible

Much of the damage at the Huachipato Steelworks was concentrated on the blast furnace and the nearby raw material tanks.. As it was essential to rake out the cooled, solidified iron (salamander) from the blast furnace, the mission of the engineers sent over from Kobe Steel was to advise on how to restore the blast furnace.

"We were working on a 'second best' basis," explains Masaaki Takeuchi. "Rather than getting everything back in perfect condition from the start, the first thing was to get the blast furnace up and running." To get the works operating again as quickly as possible, they placed top priority on essential equipment to run the facilities and on safety, and then spent time on repairs afterwards. That sense of determination was something they had learned from restoring the blast furnace at the Kobe Works following the Great Hanshin-Awaji Earthquake.

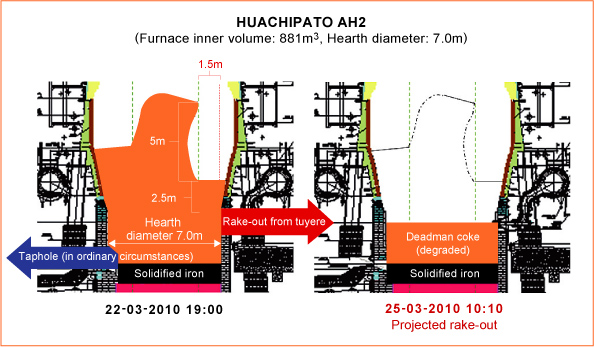

As the Huachipato blast furnace only had one taphole to extract the molten iron inside, restoration work had to be precise. The method they used to remove the hardened salamander inside the furnace was to create a new channel and blast hot air into the furnace, to ignite deadman coke in the bottom of the furnace and melt the salamander so that it could be removed. While Matsui worked on elaborate operational design formulae, Takeuchi and Kita gave advice on restoring the damaged blast furnace facilities, providing explanations for local staff with the aid of drawings. With their pride at stake, they set about achieving their mission with the aim of restoring the facilities within three months.

Plan to create a channel between the tuyere and taphole and rake out the salamander (solidified iron)

A Shared Awareness and Determination to Restore Operations, Based on 300 photos

"The most important step was to establish a shared awareness with the local engineers," recall the three engineers unanimously. In order to have the confidence to get operations up and running again, every member of staff needed to understand the restoration process and be happy with each stage, as well as understand the underlying technical methodology.

In order to establish that shared awareness, the engineers took with them a series of 300 photos of restoration work after the Great Hanshin-Awaji Earthquake to show to their local counterparts. Actually visualizing their experiences and actions helped overcome the time and distance between the two sides to create a shared awareness, paving the way to get the furnace back up and running.

One of the 300 photos used by the engineers

(Restoration work on the No. 3 Blast Furnace at the Kobe Works)

Coming Away with a Sense of Global Solidarity between Engineers

So what did the engineers get out of their assignment in Chile? "A sense of solidarity with our fellow engineers, based on shared experiences," answers Matsui. "The experience of putting our legacy from the past to good use, based on our recovery from the Great Hanshin-Awaji Earthquake," says Takeuchi. "Corporate bonds forged in iron," replies Kita. The main thing that they have come away with is a sense of global solidarity, between both engineers and companies.

One of the reasons for their success was that they envisioned response measures before setting off for Chile and made decisions based on close communication with Japan. We hope that this project will serve as a model experience for overseas technical support in the future.

Operations restarted again at the Huachipato Steelworks on June 9, 2010, the 103rd day after the earthquake. The message of thanks that we received on that day is something that the entire Kobe Steel Group will treasure.

A meeting with specialist staff at Huachipato Steelworks

Comments from the leader of the restoration support project

Contributing to Society and the Environment through the Technical Capabilities of the Kobe Steel Group

Shinji Kitano

Then-General Manager, Ironmaking Department,

Kobe Works, Kobe Steel

|

The Kobe Works sustained serious damage during the Great Hanshin-Awaji Earthquake. The damage to our blast furnace was particularly serious, making the road to recovery an extremely difficult one. Nothing makes us happier than putting the technical capabilities that we gained as a result of that experience to good use, in order to help people in other parts of the world. We would like to offer our sincerest sympathies to everyone affected by the Great East Japan Earthquake. We will continue to do everything we can here at the Kobe Steel Group to contribute to society and the environment |

|