[Supplementary Material for Integrated Report 2018]CO2 Emissions and Initiatives to Reduce CO2

In response to global warming, the Kobe Steel Group promotes rationalization and R&D to reduce energy consumption throughout its operations in an effort to decrease greenhouse gas emissions.

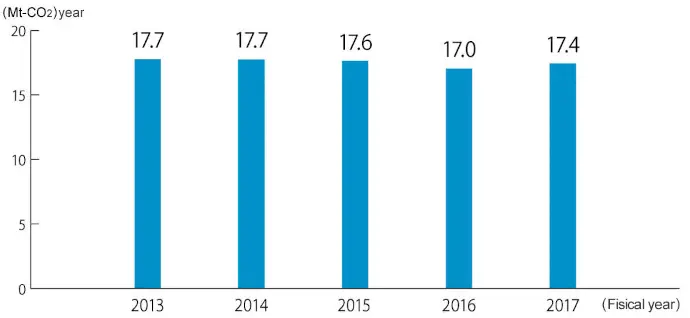

Iron & Steel Business

The Iron & Steel Business has been pursuing various improvements to its facilities and operations.

Emissions for fiscal 2017 increased 2 percent compared with the previous year.

In the future, we will continue to implement energy conservation measures and reduce environmental impact, striving to achieve industry targets described in Nippon Keidanren's Commitment to a Low Carbon Society.

CO2 Emission Trends for the Iron & Steel Business (Kobe Steel, Ltd.)

- *Preliminary calculations for Iron & Steel Business totals include coke production.

- *As emission factors from purchased power in fiscal 2017 have yet to be announced, results for fiscal 2016 were used.

- *Emissions for past years have been recalculated due to revisions to electric power coefficients, etc.

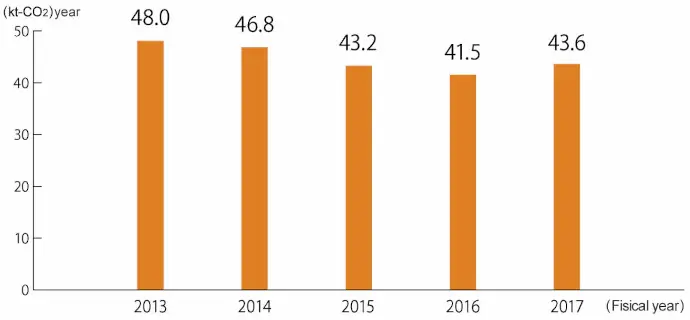

Welding Business

The Welding Business aims to thoroughly increase plant efficiency and reduce energy loss.

In fiscal 2017 we introduced LED lighting, installed inverters at plants, and carried out other similar, systematic initiatives at all locations.

Emissions for fiscal 2017 increased by 5 percent compared with the previous year.

In the future, we will continue to pursue additional energy-saving measures and further reduce environmental impact.

CO2 Emission Trends in the Welding Business (Kobe Steel, Ltd.)

- *Emissions for past years have been recalculated due to revisions to electric power coefficients, etc.

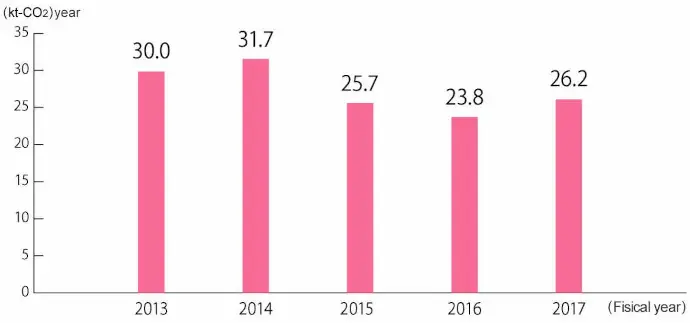

Aluminum & Copper Business

The Aluminum & Copper Business has been switching from oil-based fuels to natural gas, as well as striving for greater energy efficiency through improvements to productivity and introduction of highly efficiency equipment.

Improvements made in fiscal 2017 included introduction of highly efficient boilers, LED lighting and fan inverters.

Emissions for fiscal 2017 increased by 3 percent compared with the previous year.

In the future, we will continue to implement energy conservation measures and reduce environmental impact, striving to achieve industry targets described in Nippon Keidanren's Commitment to a Low Carbon Society.

CO2 Emission Trends for the Aluminum & Copper Business (Kobe Steel, Ltd.)

- *Emissions for past years have been recalculated due to revisions to electric power coefficients, etc.

Machinery Business

As demand for energy-saving compressors, heat pumps and other products increases, the Machinery Business is striving to improve energy efficiency through high-efficiency equipment, higher productivity, and advice from energy-saving consultants.

Emissions in fiscal 2017 increased by 10 percent compared to the previous year.

In the future, we will continue to implement energy conservation measures and reduce environmental impact, striving to achieve industry targets described in Nippon Keidanren's Commitment to a Low Carbon Society.

CO2 Emission Trends for the Machinery Business (Kobe Steel, Ltd.)

- *Emissions for past years have been recalculated due to revisions to electric power coefficients, etc.