Response to Climate Change

The Challenge of Carbon Neutrality

Reduction of CO2 emissions in production processes —CO2 Reduction Solution for Blast Furnace Ironmaking—

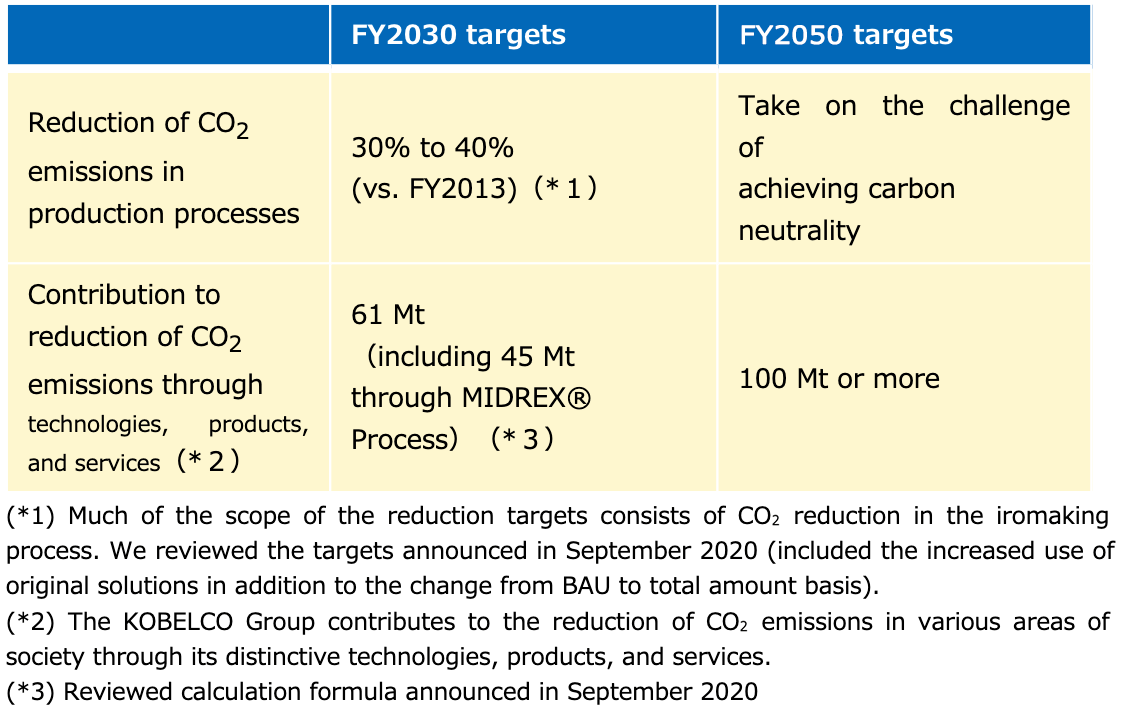

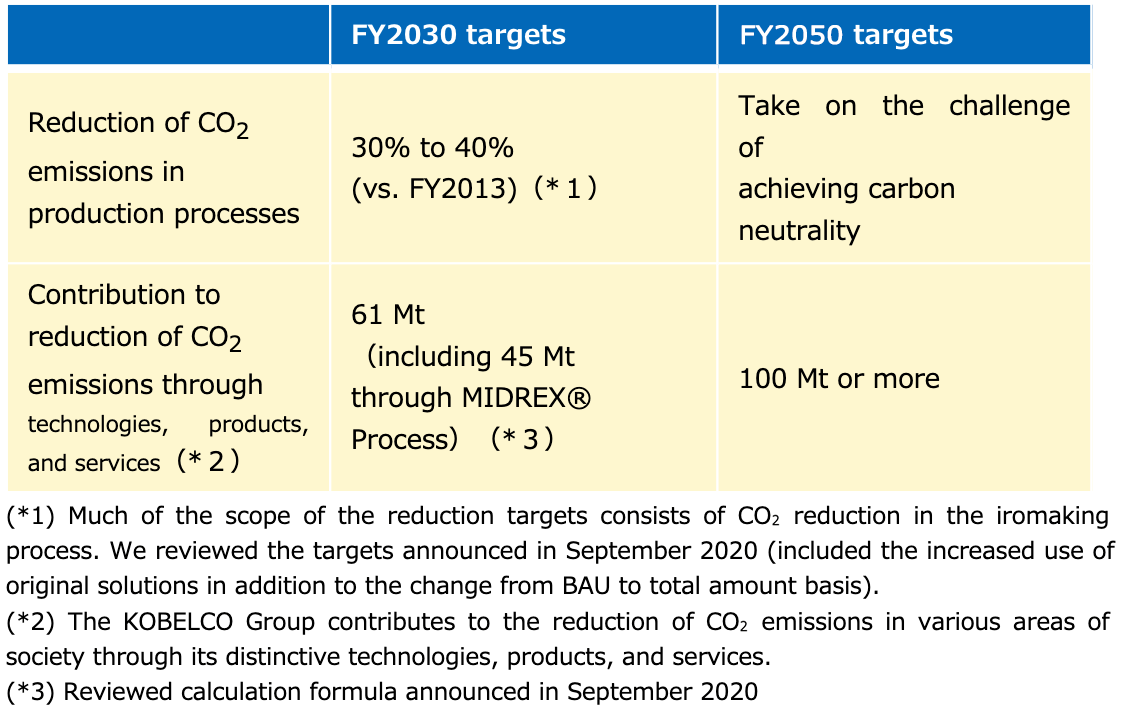

In addition to reducing CO2 emissions in production processes, the KOBELCO Group contributes to reducing CO2 emissions through our unique technologies, products, and services. We have set 2030 targets and 2050 vision for these two areas.

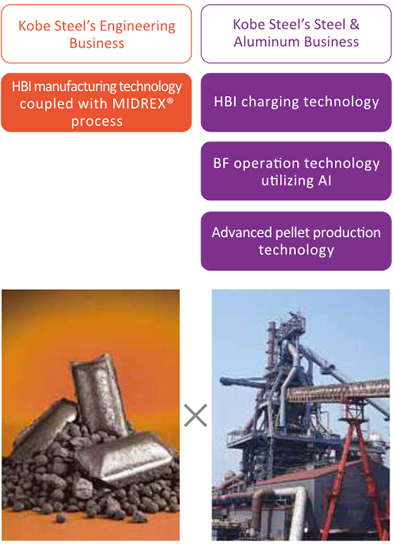

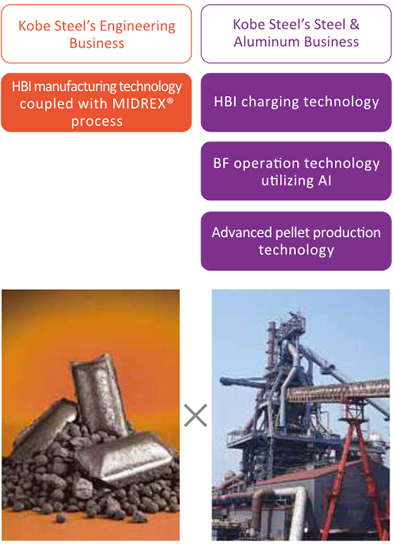

● Kobe Steel has successfully demonstrated the technology that can reduce a significant amount of CO2 emissions from blast furnace operations, combining the technologies of Midrex and the blast furnace operation technology. This achievement is a result of the integrated efforts of the KOBELCO Group leveraging its diverse businesses. The demonstration test was conducted at Kakogawa Works in Hyogo Prefecture, Japan in October 2020.

● The quantity of CO2 emissions from the blast furnace is determined by the quantity of carbon fuel used. In the demonstration test, the quantity of carbon fuel was stably reduced from 518 kg/tHM (ton hot metal)*1 to 415 kg/tHM by charging a large amount of hot briquetted iron (HBI) produced by the MIDREX® Process. The results indicate that this technology can reduce CO2 emissions by approximately 20% compared to a conventional method*2. In addition, the world's lowest level of coke rate (239 kg/tHM) has been achieved.

We see this technology as a promising solution that could become readily available in the near future at a lower additional cost compared to other CO2 reduction measures. This solution, after being made public, has been attracting a growing interest from stakeholders as well as from domestic and international media.

*1: Ton hot metal (tHM) indicates the amount of raw materials required for production per ton of hot metal.

*2: Comparison with fiscal 2013, the base year of the CO2 reduction targets set by the government and the KOBELCO Group.

This low CO2 blast furnace operation technology was developed combining the KOBELCO Group's unique technologies

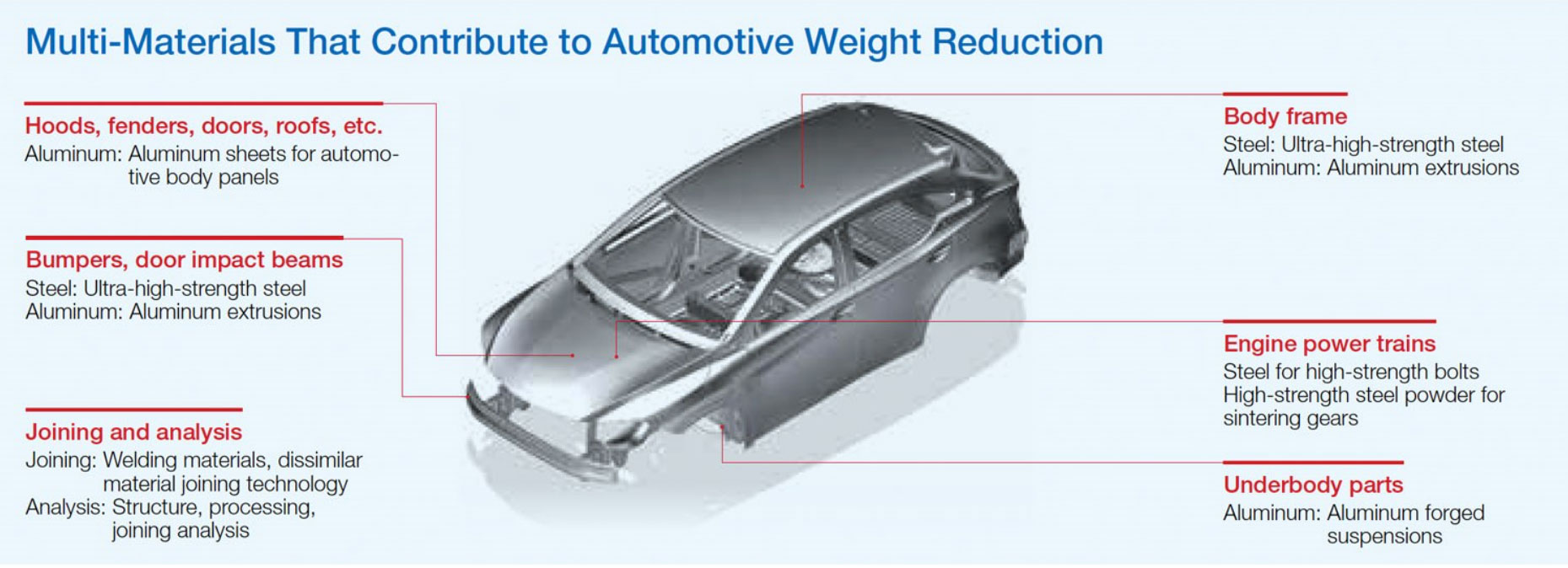

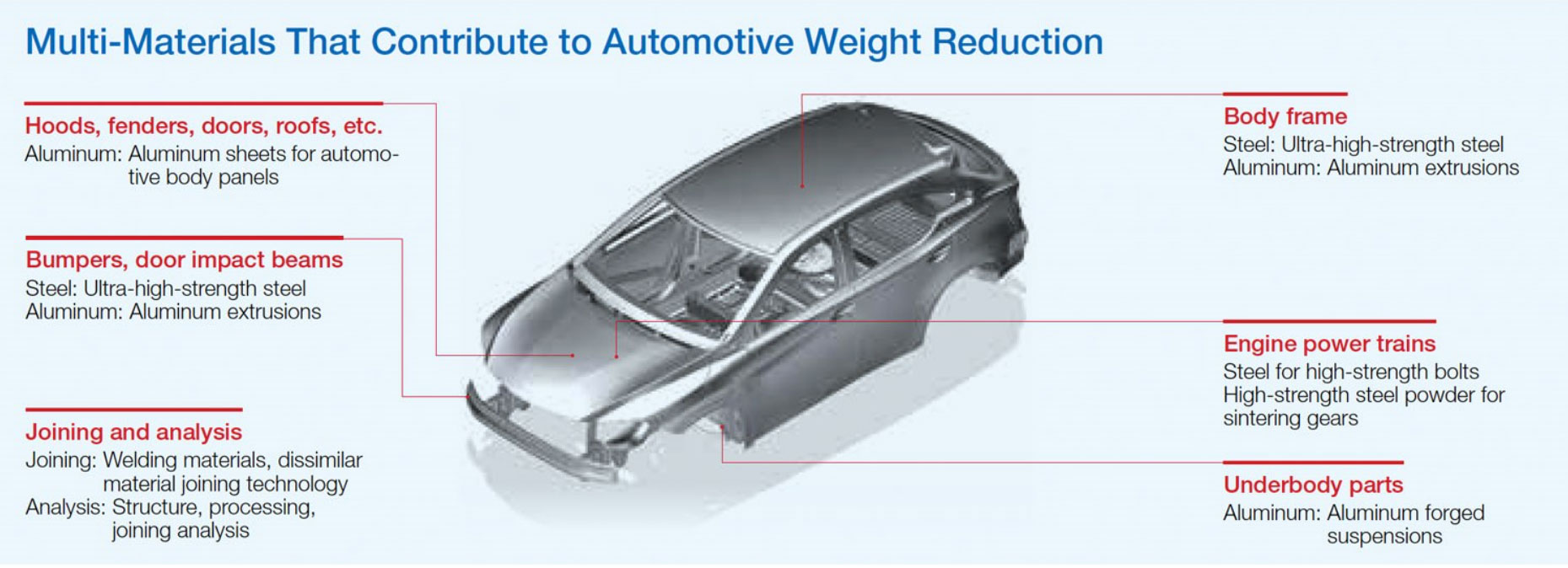

Contributing to Reduction of CO2 Emissions in the Automotive Field

● Promoting the Use of Electric Vehicles

by Supplying Unique Products

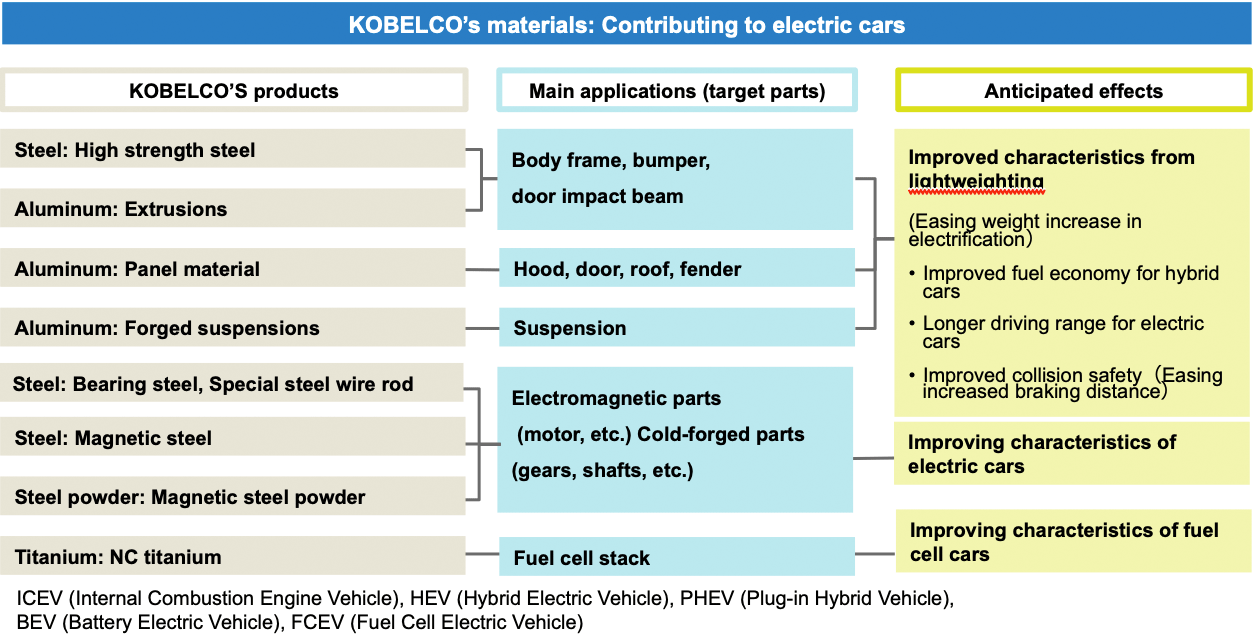

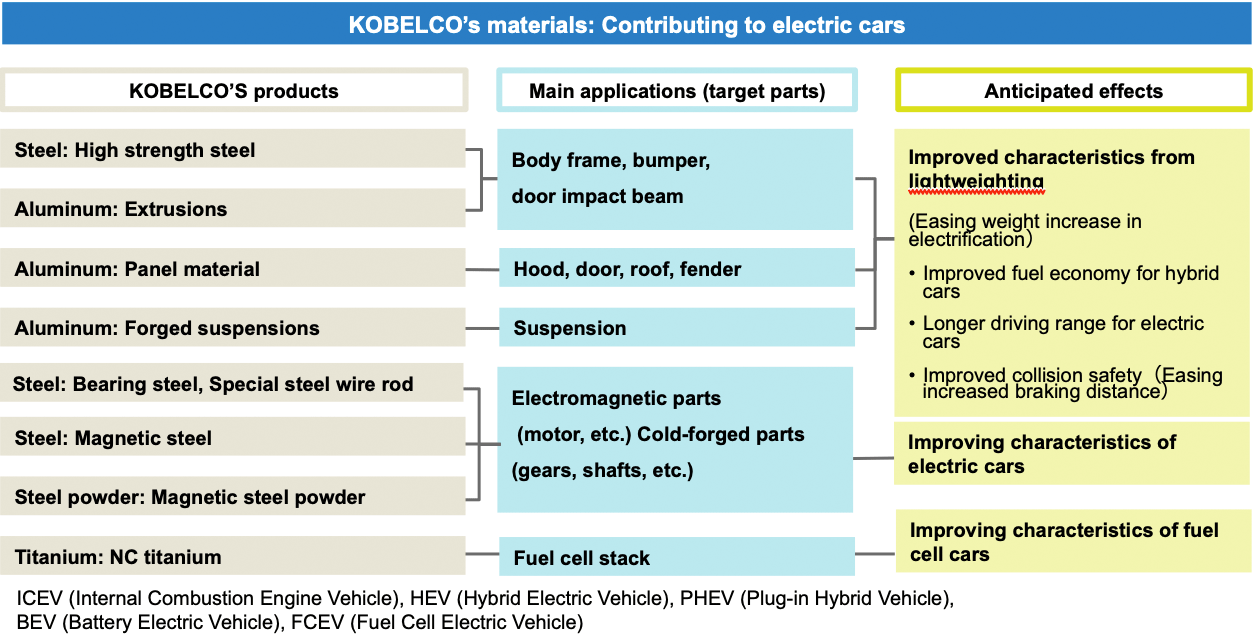

○ Many countries have set goals for electrification as an initiative for carbon neutrality. Automakers’ initiatives for electrification will further accelerate in the future.

○ Automotive weight reduction is not only about improving the fuel economy of gasoline cars. Lightweighting plays an important role in improving the fuel economy of hybrid cars and extends the driving range of electric cars. Responding to the need for lighter materials, KOBELCO contributes to accelerating electrification.

○ We contribute to automakers’ initiatives for carbon neutrality with a variety of products for electric cars, including wire rods/bars (bearing steel, special steel, pure iron soft magnetic steel), magnetic steel powder, titanium for fuel cell stacks.

● Contributing to Energy Conservation

and Fuel Efficiency through Compressors

for LNG Fuel Ships with Low Environmental Impact

We will improve energy efficiency and fuel efficiency in the transport field and ensure safety, security and prosperity in people’s lives.

Tighter environmental regulations have led to major changes around the world for large ships that are the backbone of marine transportation. Needs are increasing for better fuel economy and energy conservation in the operation of large ships.

Demand is growing for LNG-fueled ships, which have a smaller environmental footprint than traditional ships in response to tightening environmental regulations for SOx and NOx emissions. Kobe Steel has supplied a large number of compressors used in LNG-fueled ships and holds a large share of the market for these compressors. Through providing these products, we will continue to contribute to solutions for global issues.

Promoting Resource Recycling

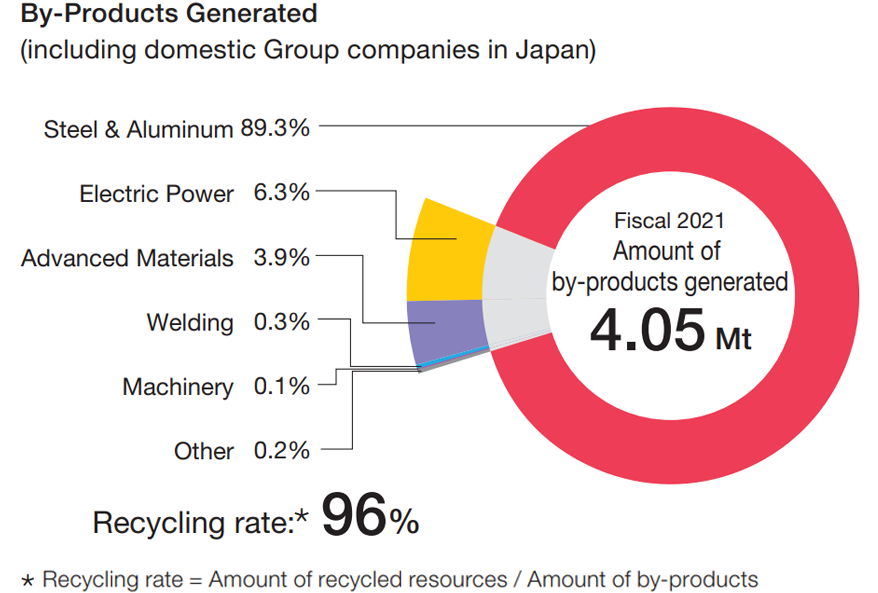

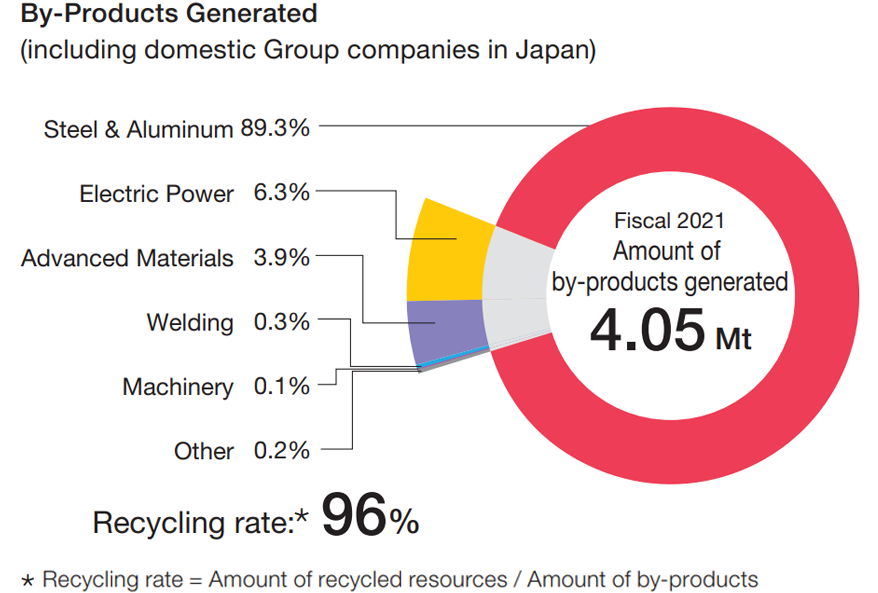

Seeking to make effective use of limited resources, we are working to reduce the generation of waste and actively promoting recycling by increasing the added value of by-product materials from production processes and developing and introducing new applications.

In fiscal 2020, the Group generated 3.2 million tons of by-product materials, with the steel and aluminum businesses ccounting for around 87%. We are also actively working to improve yield and reduce the use of by-product materials and have set a target of 99% for recycling of slag, dust, and sludge in fiscal 2025. Our recycling rate in

fiscal 2020 was 98.7%. We will continue striving to achieve our target.

Resource recycling through technology, products, and services

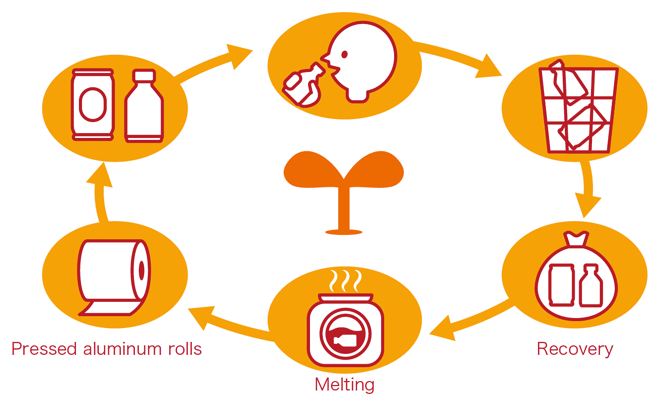

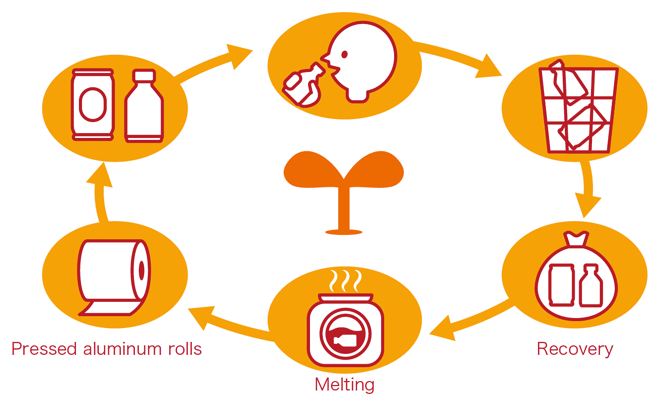

● Reducing Plastic Waste and Contributing to the Preservation of the Marine Environment through the Manufacturing of Aluminum Can

We will realize a recycling-oriented society and protect the marine environment.

A key social issue today is the realization of a recycling-oriented society (a society where the burden on the environment is reduced as much as possible by restricting the consumption of natural resources), which was codified into law in Japan in 2000.

The KOBELCO Group aims to help preserve the marine environment by slowing the increase in plastic waste, especially plastic bottles, which is a growing social concern of late, through the production of highly recyclable* aluminum can stock.

* In Japan, the aluminum can recycle rate was 97.9% in 2019.

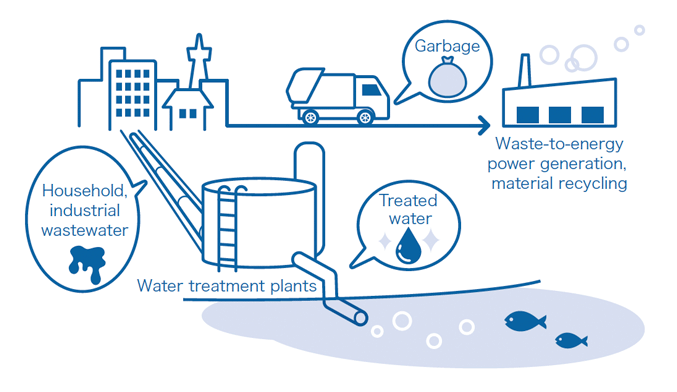

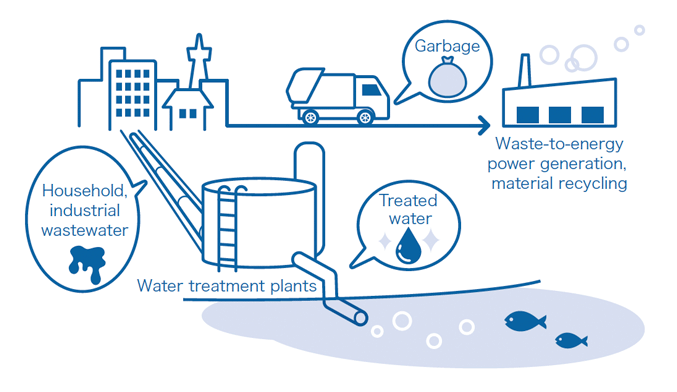

● Securing Safe Water and Creating a Sustainable Environment through Water/Waste Treatment Business

We will contribute to the creation of an environment where people can continue to enjoy safe, secure, and prosperous lives through our technologies, products, and services that reduce environmental impact.

People’s health and living environments rely on the proper maintenance of waterworks infrastructure and disposal of waste.

Kobelco Eco-Solutions Co., Ltd. is operating businesses around the world for detoxifying PCBs, treating municipal waste, and treating water, both in water supply and wastewater. Through the water/waste treatment businesses, we contribute to securing safe water sources and the creation of sustainable communities.