We will contribute to the stable supply of energy to local communities, the provision of products that meet customer needs, and the improvement of safety and productivity at customer manufacturing sites.

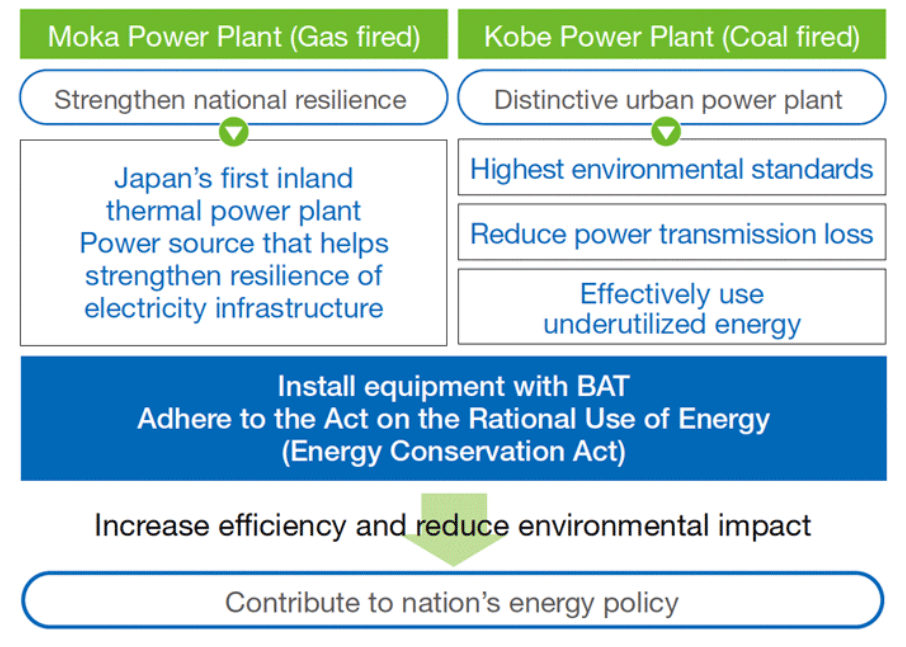

<Moka Power Plant>

2The No. 1 and No. 2 units of the Moka Power Plant began operation in fiscal 2019. These units, being supplied with city gas as fuel, generate electricity at the highest level of efficiency in Japan by deploying a cutting-edge gas turbine combined cycle power generation system. The Moka Power Plant is the Japan’s first inland full-fledged thermal power plant, located in a safe area with low probability of earthquakes and zero risk of damage from tsunamis. With this dispersion of risks, the Cabinet Secretariat selected the Moka Power Plant as an example of facilities that contribute to improving the resilience of the nation and its energy infrastructure. The Moka Power Plant also contributes to increasing the electricity self-sufficiency rate of Tochigi Prefecture.

<Kobe Power Plant>

The Kobe Power Plant is capable of reliably supplying electric power with excellent economic viability, owing to the Company’s in-plant coal infrastructure and accumulated know-how in operations of coal-fired power generation facilities.

The Kobe Power Plant is located in an urban area close to sources of demand and implements high standards in environmental measures, enabling the highly efficient supply of clean electric power with little power transmission loss, thereby contributing to higher self-sufficiency in electric power for cities in the region.

*S+3E Safety+Energy Security, Economic Efficiency, Environment

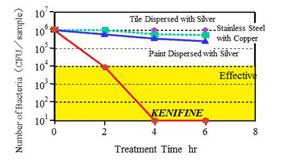

The advanced antibacterial plating technology KENIFINE™, developed by the Materials Research Laboratory, Kobe Steel, Ltd. in 2001, is a nickel-based special alloy plating technology that was originally developed after the food poisoning incident caused by pathogenic Escherichia coli O157 that shook Japan in 1996. It is effective not only in antibacterial and antiviral properties, but also in mold and slime resistance.

With an aim to provide safety, security, and prosperity to people’s lives, our company has been licensing other companies to use the KENIFINE technology, centered on food machinery and kitchen appliances, as well as medical and welfare related industries. As a result of not monopolizing the market, applications have expanded to include transparent films, aquaculture, hydroponics, amusement, textile/apparel, and judo tatami mats.

To continue to provide safety, security, and prosperity to people’s lives, we have been conducting verification of the effectiveness against the novel coronavirus with a third-party organization by utilizing the technologies, know-how, and experiences we have accumulated over more than 20 years

Industrial robots for welding have the potential to change the way we work by reducing the workload amid labor shortages at worksites, while also ensuring the health and safety of workers.

The KOBELCO Group supplies REGARC™-equipped structural steel welding systems mainly in Japan that is facing the falling birthrate and an aging population. We aim to provide solutions to the needs of global society by responding to a potential demand rise for welding robots overseas, which is expected in the future.

We will utilize the automated guideway transit (AGT) technologies and contribute to the alleviation of traffic congestion and the development of transport infrastructures.

Maintaining transportation infrastructure has a major impact on economic development, as well as the improvement of living conditions. Kobe Steel owns self-driving technologies that have been developed through supplying new transit systems like the Port Liner and Yurikamome. We are expanding these technologies across not only Japan but also other Asian countries. Kobe Steel participated in the construction of Indonesia’s first subway line, the North-South Line of the Jakarta Mass Rapid Transit system, which opened in April 2019, contributing to core infrastructure that eases chronic traffic jams in Jakarta and improves the urban environment.