Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2012 > Proper Control of Chemical Substances

Proper Control of Chemical Substances

Proper Control of Chemical Substances

At the Kobe Steel Group, we make sure that all chemical substances are adequately controlled in accordance with domestic and international standards. We work hard to reduce the quantities of hazardous materials that we use and substitute them with safer alternatives.

Thorough Control of Chemical Substances

![]()

Having set out the Kobe Steel Group Policy on Controlling Hazardous Substances, we make every effort to effectively control chemical substances. The Management Sheets for Designated Chemical Substances are used by all group companies to clearly specify usage and control methods for each substance. Sheets are used to calculate volumes transferred or released for notification in accordance with the PRTR Act*1 and also as part of activities aimed at reducing consumption and emissions of chemical substances.

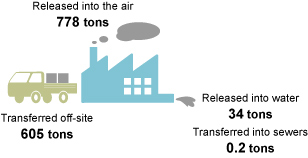

Notifications submitted in accordance with the PRTR Act, which has now been revised to include additional designated chemical substances, indicate that the Kobe Steel Group handled 52 designated substances, released*2 approximately 812 metric tons and transferred*3 approximately 605 metric tons in fiscal 2011.

*1 PRTR Act: Pollutant Release and Transfer Register: Legislation that requires notification of the releases of designated chemical substances into the environment and promotes improved controls.

*2 Combined total for chemical substances released into the air and water

*3 Combined total for chemical substances transferred off-site or into the sewers

Chemical Substances Released and Transferred by the Kobe Steel Group

Chemical Substances Released and Transferred by the Kobe Steel Group

Meeting Regulations on Chemical Substances

![]()

Regulations on chemicals substances are becoming increasingly strict, not only in Japan but all over the world. With revised versions of the Act on the Evaluation of Chemicals Substances and the Regulation of their Manufacture and the PRTR Act coming into effect in Japan, we take all necessary steps to ensure compliance here at the Kobe Steel Group.

As well as reducing chemical emissions through ongoing activities within the group, such as those outlined in the table below, we are also working to share information and exchange opinions between departments in order to ensure adequate compliance with all relevant legislation.

Controlling Waste Electrical Equipment Containing PCBs

![]()

In compliance with government regulations on the proper handling of waste containing polychlorinated biphenyls (PCBs), we place used transformers, condensers and other equipment containing PCBs in special storage and notify the authorities of the details.

We began outsourcing the disposal of PCBs at Kobe Steel in fiscal 2008 and continued to do so at each of our works (Kakogawa Works, Kobe Works and Takasago Works) during fiscal 2011.

Activities Aimed at Reducing Chemical Emissions

![]()

| Company name | Location of plant | Examples of Measures Implemented |

|---|---|---|

| Shinko Kenzai, Ltd. | Amagasaki, Hyogo | Replacing pretreatment chemicals, paints and other substances used in coating processes with environmentally friendly alternatives |

| Kobelco Construction Machinery Co., Ltd. | Ogaki, Gifu | Reducing re-coating through Coating Quality Improvement Project activities, reducing usage of organic solvents |

| Kobelco Machinery Asia Pte. Ltd. | Singapore | Improving pretreatment processes, reducing usage of cleaning thinner |

| Kobelco Compressors America, Inc. | California, USA | Reinforcing water-based washing procedures for stainless components in order to reduce usage of cleaning chemicals |

| Kobe Welding of Tangshan Co., Ltd. | Tangshan, Hebei, China | Using filtration system to reuse and reduce consumption of lubricants and lubricant oils |