[Supplementary Material for Integrated Report 2019]Disaster Prevention Initiatives

The Kobe Steel Group makes groupwide efforts to comply with laws and regulations, implement measures to prevent facility accidents, and prepare for natural disasters.

The Group has established disaster prevention systems and holds regular emergency drills. We are actively undertaking these measures to prevent accidents from occurring and to minimize damage if a disaster does strike.

We will continue to raise each and every employee's awareness for disaster preparedness while continuing to carry out disaster prevention activities throughout the Group.

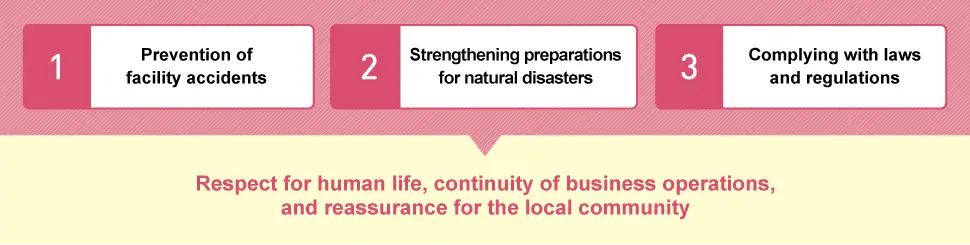

Companywide Disaster Prevention Management Policy

Chief officer responsible for

companywide disaster prevention

(Senior Managing Executive Officer)

We engage in disaster prevention activities, with the aim of becoming a corporate group that is trusted by the community and society.

At the Kobe Steel Group, disaster prevention activities are carried out according to three basic principles: prevention of facility accidents, strengthening preparations for natural disasters, and compliance with disaster-related laws and regulations.

To prevent facility accidents, we share case studies of accidents and take thorough measures to prevent a recurrence of similar accidents. To strengthen preparations for natural disasters, we take structural measures such as seismic reinforcement and anti-flood measures and also implement response drills for large-scale earthquakes. Regarding compliance with disaster-related laws and regulations, we have verified the status of compliance at each business location through document and on-site reviews.

In preparing for large-scale earthquakes that are anticipated to occur in the near future, such as the Nankai Trough Earthquake and a large-scale earthquake expected to hit the Tokyo area, we will continue to take every necessary action, including efforts to enhance the sophistication of our BCP, not forgetting the lessons learned from the Great Hanshin Earthquake of 1995 and the Great East Japan Earthquake of 2011. In this way, we aim to be a corporate group that is resilient to disasters and that has the trust of the community and broader society.

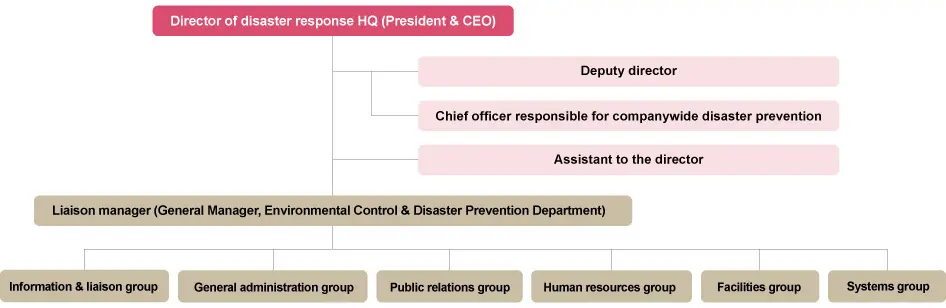

Companywide Disaster Prevention Management Structure

At the Kobe Steel Group, the head office, business units, business locations, and Group companies all promote disaster prevention management activities under the supervision of the president and the chief officer for companywide disaster prevention.

Kobe Steel Group Disaster Prevention Meeting

We organize the Kobe Steel Group Disaster Prevention Meeting every year in an effort to share information and strengthen disaster prevention initiatives. A total of 104 employees from 41 Group companies took part in our fiscal 2018 meeting. This year we invited an outside instructor who gave a talk entitled “BCPs for Corporate Survival,” about the importance of a BCP. We also renewed our awareness of the importance of disaster prevention by sharing information on case studies of those afflicted by the Osaka earthquake and heavy downpours in western Japan, both in 2018, as well as cases of disaster prevention trouble.

Countermeasures for Facility-Related Accidents

The Kobe Steel Group makes every effort to prevent fires and other accidents before they occur. We will keep striving to prevent accidents throughout the Kobe Steel Group, including by sharing information in and outside the company; making thorough efforts to prevent recurrences of accidents, including similar accidents; and taking special initiatives in coordination with voluntary action plans from industry associations.

Business Continuity Plan (BCP)

The Kobe Steel Group is proceeding with the formulation of a BCP, the basic policies of which are: (1) ensuring the lives and safety of employees, and (2) ensuring the supply of products and services to customers. As one initiative so far, we have conducted seismic reinforcement and taken anti-flood measures according to the location conditions of each site, in order to reduce damage from natural disasters such as earthquakes and tsunamis. At present, we are mainly working at further enhancing business plans for the restoration period.

In the event of heavy damage being sustained due to a large-scale earthquake, etc., we will establish a disaster response headquarters in the head office and provide support to business locations with the aim of achieving a quick restoration.

We carried out drills for establishing a disaster response headquarters using transceivers, which are effective for communication during a disaster, based on the scenario of damage over a wide area caused by a major earthquake in the Nankai Trough. In order to be prepared in the event of an emergency, we will continue to train and hold drills to ensure even smoother responses in the future.

KOBELCO 1.17 Walk

To prevent memories of the Great Hanshin Earthquake from fading, we held the KOBELCO 1.17 Walk on January 26, 2019 to check the routes employees use for commuting in the event that public transportation becomes unavailable due to an earthquake or other disaster.

The 62 participants each took a Map to Help You Return Home in a Disaster, which had been distributed in advance, and walked while noting areas near the route that would be submerged in a tsunami as well as the location of convenience stores, public toilets and other points of interest. We plan to continue this event at the Kobe Head Office and Tokyo Head Office in the future.

Disaster Prevention Inspections

We conduct document inspections and on-site inspections of Kobe Steel Group facilities in order to verify compliance with disaster prevention laws and regulations and to minimize risks that could potentially lead to accidents.

In the future, we will continue to reinforce the disaster prevention management structure throughout the Kobe Steel Group.