Kobe Steel completes liquid hydrogen open rack vaporizer demonstration test

Jul. 16, 2025

Kobe Steel, Ltd.

Kobe Steel, Ltd. announces that it completed a demonstration test*1 of its Open Rack Vaporizer (ORV)*2 for liquid hydrogen at the Company’s production site Takasago Works (Hyogo Prefecture, Japan) in March.

In this demonstration, the newly developed ORV for liquid hydrogen stably achieved the specified vaporization performance targets—namely, the vaporized gas flow rate and temperature— throughout continuous operation. Following the successful completion of this demonstration test, we are now ready to deliver the following three types of liquid hydrogen vaporizers to the market.

- 1Intermediate Fluid Vaporizer (IFV)*3

— Its demonstration test using liquid hydrogen completed in March 2023.

- 2Printed Circuit Heat Exchange (PCHE)*4

— Its demonstration test using liquid hydrogen completed in March 2024.

- 3Open Rack Vaporizer (ORV)

— Its demonstration test using liquid hydrogen completed in March 2025.

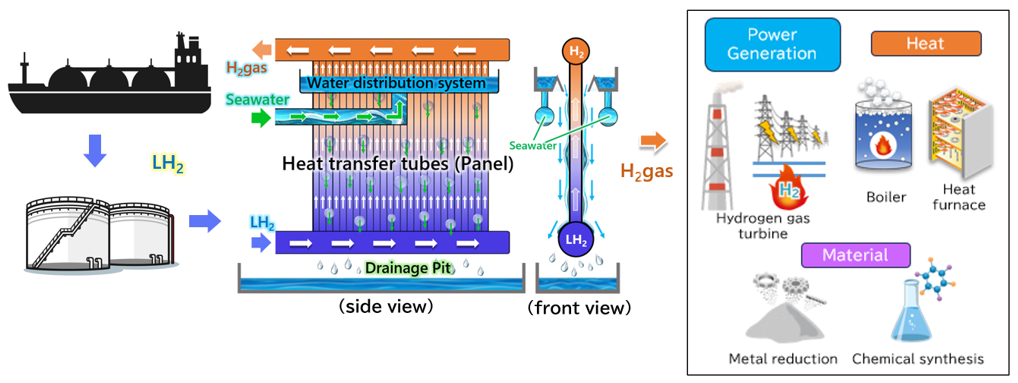

Liquid Hydrogen ORV & Hydrogen utilization

| Liquid Hydrogen (Transport・Storage) |

Liquid Hydrogen ORV | Hydrogen Utilization |

|---|---|---|

|

||

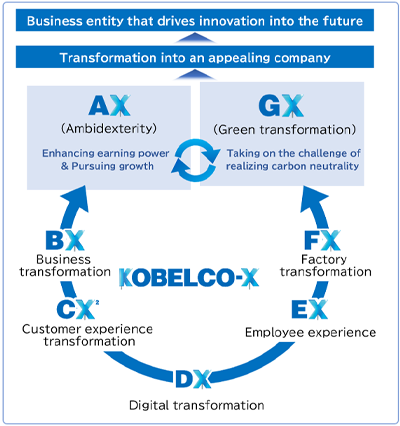

The Kobe Steel Group, also known as the Kobelco Group, is working on two priority issues: (1) enhancing earning power and pursuing growth and (2) taking on the challenge of realizing carbon neutrality, as set out in the Medium-Term Management Plan (Fiscal 2024–2026). As part of this effort, we are promoting an initiative called KOBELCO-X*5, which spans a wide range of transformations. The demonstration of the liquid hydrogen open rack vaporizer is linked to AX (Ambidexterity) and GX (Green transformation), as it helps reduce CO2 emissions during combustion and replace carbon-intensive fuels used in the industrial furnace with hydrogen by providing vaporized hydrogen gas for combustion testing in a heating furnace at Takasago Works and for other purposes. Utilizing our demonstration facilities, we will continue to explore hydrogen applications and new business opportunities.

This successful demonstration will pave the way for gaining new business opportunities by demonstrating our comprehensive capabilities that enable both hydrogen production and utilization (an AX effort), while also contributing to decarbonization through reducing CO2 emissions in the production process by making a new liquid hydrogen vaporizer available (a GX effort).

In addition to developing a wide range of technologies related to hydrogen supply (“production”), we are also actively conducting demonstrations of fuel-based applications (“utilization”) at our own plants, which have the potential to become large-scale hydrogen utilization facilities. By leveraging insights from both the production and utilization perspectives, our Group will continue to provide unique, optimal solutions and contribute to achieving a hydrogen society, as we strive for a world in which people, now and in the future, can fulfill their hopes and dreams while enjoying safe, secure, and prosperous lives.

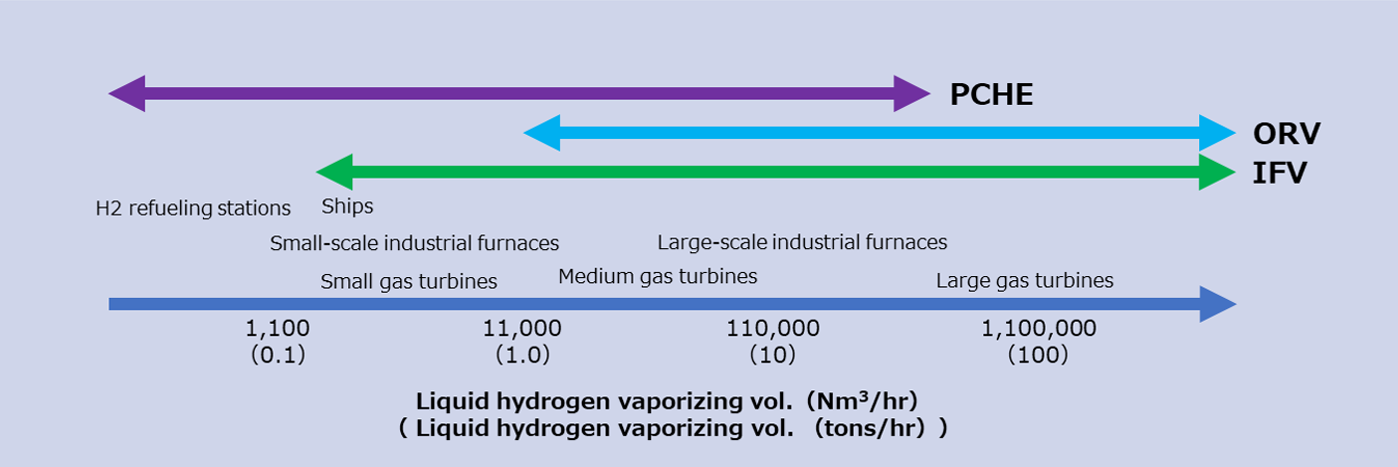

Liquid hydrogen vaporizer product lineup

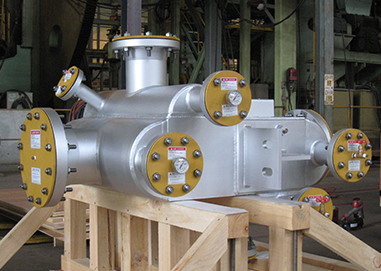

| Type | (1) IFV | (2) PCHE | (3) ORV |

|---|---|---|---|

| Appearance |  |

|

|

| Features |

Material: Stainless steel, titanium (for seawater)

|

Material: Stainless steel

|

Material: Aluminum alloy + thermal spray

|

| Demo Schedule | Completed in March 2023 | Completed in March 2024 | Completed in March 2025 |

Vaporizing volume by application

- *1Liquid hydrogen open rack vaporizer demonstration test

- *2Open Rack Vaporizer (ORV)

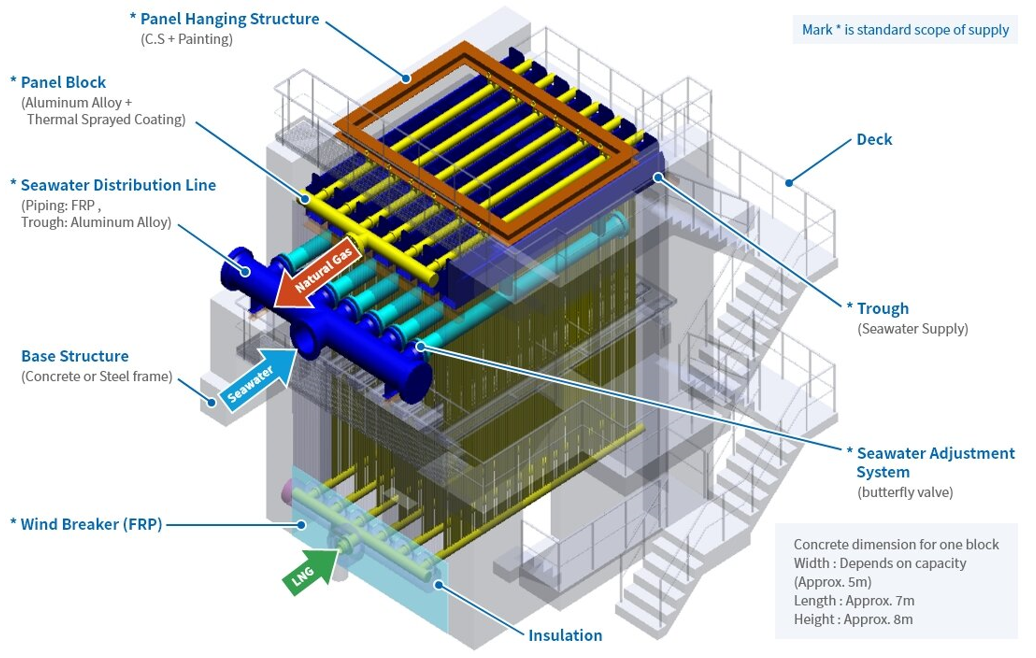

In many LNG receiving terminals around the world, ORVs function as base-load LNG vaporizers utilizing seawater as a heating medium. Kobe Steel, one of the world’s leading ORV manufacturers, has nearly 50 years of experience and a proven track record of reliability in this field. We developed the ORV for liquid hydrogen by leveraging our expertise in the design and manufacture of vaporizers. Our ORV is designed to vaporize liquid hydrogen inside by pouring seawater over the heat transfer panel, which is composed of aligned heat transfer tubes.

ORV for LNG Structure Illustration

- *3Intermediate Fluid Vaporizer (IFV)

- *4Kobe Steel’s PCHEs are commercialized under the brand name of Diffusion-bonded Compact Heat Exchanger (DCHE)

- *5KOBELCO-X (Medium-Term Management Plan (Fiscal 2024–2026))

- *The information on this web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.