Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2010 > Products, Technologies and Services that Contribute to the Environment

Products, Technologies and Services that Contribute to the Environment

Products, Technologies and Services that Contribute to the Environment

| Providing products, technologies and services to help industry and society in a wide range of fields reduce the environmental impact |

|

UBC® low-grade coal conversion technology designed to effectively utilize untapped coal resources

| Short for upgraded brown coal, UBC® is a technology that upgrades low-grade coal such as brown coal, which is widely available in Indonesia but has been largely unused due to its high water content. Kobe Steel launched operations at a large-scale demonstration plant in Indonesia in December 2008 with the aim of developing the UBC Process for the power industry. With production running at up to 600 tons a day, the plant is providing large samples of UBC to a number of power stations in Japan. |

|

UBC briquettes |

UBC demonstration plant in Satui, Indonesia |

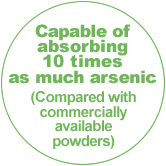

ECOMEL® Series environmental iron powders designed to purify contaminated soil and wastewater

| Kobe Steel has been developing ECOMEL® environmental iron powder with the aim of contributing to society in a new way by using atomized iron powder to combat the increasingly serious issue of groundwater and soil contamination. In addition to our iron powder for breaking down volatile organic compounds, which already have a proven track record, our newly developed ECOMEL® powder for absorbing and purifying arsenic has now been used for the first time in Hokkaido. The new ECOMEL® powder alloys components that stimulate arsenic absorption reactions and have outstanding absorption capabilities, absorbing ten times as much arsenic as commercially available powders. As ECOMEL® powders are also capable of purifying substances such as serene, chromium, lead and cadmium, they are expected to be used for an increasingly wide range of purposes in the future, such as tackling heavy metal and compound contamination. |

|

|

ECOMEL® atomized iron powder |

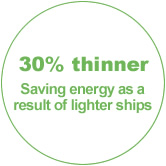

47kg steel plate used on large-scale car carrier for the first time

| Steel plate with a yield point of 47kg developed by Kobe Steel has been used on a large-scale car carrier built by Imabari Shipbuilding Co. Ltd. The 47kg steel plate will be used for the traverse bulkhead of the large-scale car carrier. This is one of the parts of the ship that is subject to the highest levels of stress and therefore requires steel plate with a thickness of over 50mm. As our steel plate can be made roughly 30% thinner than conventional steel plate, it has added benefits such as saving energy, as a result of lighter ships, and increasing productivity. We intend to extend applications to a wide range of other ships and parts in the future. |

|

TopicsDevelopment of high-strength steel plate provide ships with improved structural safety presented with Contribution Award at the 42nd Ichimura Industrial Awards

|

||||||||

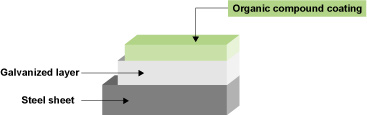

Zinkobella GX-COTE Series chromate-free surface treated steel sheet

| In 1998, Kobe Steel was the first in the steel industry to market a chromate-free steel sheet, Zinkobella GX-COTE, as a substitute for chromate-coated electrogalvanized steel sheet. Since then, chromate-free products have been consistently upgraded and now all galvanized steel sheets are chromate-free. It is now possible to offer customers a higher grade product to help reduce their environmental impact, and the working environment at steelworks has also benefited. |

|

Chromate-free steel sheet

TopicsChromate-free steel sheet awarded 36th Environment Prize

|

||||||||

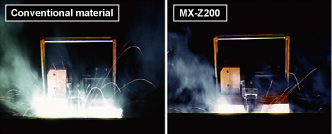

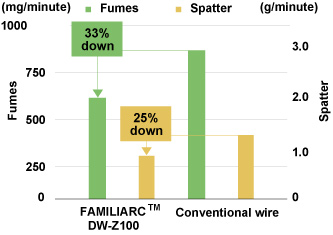

Low-fume, low-spatter welding materials

| During the welding process, the high temperature arc inevitably produces metal vapor (fumes) and metallic debris (spatter). Kobe Steel has developed a range of groundbreaking low-fume, low-spatter welding materials (FAMILIARCTM Z-44, DW-Z100, MX-Z200, etc.) that significantly reduce the volume of fumes and spatter produced during welding, thereby helping to improve working environments for welders and reducing their workload. Reducing the volume of fumes produced will also help minimize environmental impact in various ways, including reducing air pollution, bad odors and noise and saving energy wasted on removing spatter from steel plates. |

Comparison of fumes produced using FAMILIARCTM MX-Z200 |

The low-fume, low-spatter performance of FAMILIARCTM DW-Z100

|

|

Environmentally friendly, corrosion-resistant cutting aluminum

| The KE (Kobe Ecology) Series of 100% lead-free extruded cutting aluminum alloys developed by Kobe Steel is a range of environmentally friendly alloys that offer improved resistance to corrosion whilst still providing the same outstanding level of cutting performance as free-cutting aluminum alloys containing lead. With the increasingly widespread use of automatic machinery in recent years, free-cutting aluminum alloys have tended to be the first choice of aluminum or aluminum alloy materials for processing, due to their superior properties in terms of handling metal chips. Until now, lead has always been added to free-cutting aluminum alloys in quantities of just under 1% to make chips more brittle. By rigorously controlling the structure of materials and volumes of trace elements added, in combination with heat treatment, Kobe Steel has successfully achieved an outstanding level of cutting performance without lead. |

Car ABS systems are one example (ABS framework)  |

Next-generation inverter oil-free compressor, for outstanding environmental performance

| Emeraude-Aqua developed by Kobe Steel is a high-performance water-injection, oil-free screw compressor. With excellent cooling and sealing characteristics, Emeraude-Aqua is equipped with a Kobe Steel-designed non-contact screw unit directly coupled to an inverter-drive, IPM high-speed motor, giving excellent performance covering a wide range of air volume. |

|

Emeraude-Aqua water-injection oil-free screw compressor |

High Efficiency Mini II: The Industry's Most Energy-Efficient Water-Cooled Screw Chiller

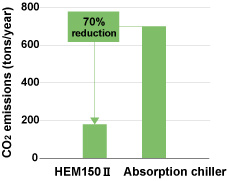

| Developed in conjunction between Kobe Steel, Chubu Electric Power Company, Tokyo Electric Power Company and Kansai Electric Power Company, the High Efficiency Mini II remains a compact feature of the conventional system, High Efficiency Mini, which has already achieved industry-leading levels of energy efficiency. With an energy efficiency rating of COP 6.0 and an annual energy efficiency of IPLV 9.2 it is the highest ranked water-cooled screw chiller in its class. In addition to significantly reducing running costs compared to other commercially available gas-fired absorption chillers, it also cuts annual CO2 emissions by 70%, making a major contribution to the environment. The High Efficiency Mini II offers a wide range of possibilities in terms of applications, ranging from air conditioning, industrial use and food processing. |

|

High Efficiency Mini II ultra-high efficiency water-cooled inverter screw chiller |

Comparison of CO2 emissions when used for industrial purposes

Operated for 8,760 hours per year (compared with 150RT)

Energy-saving air separation system

| Kobe Steel has a long and proud history as a manufacturer of air separation systems, dating back to the release of our first system in Japan in 1934. In addition to developing energy-saving processes and establishing CFC-free systems, we make the most of our expert sound technology to achieve sound levels no louder than a normal urban residential area. We were also the first air separation system manufacturer to develop environmentally friendly systems. Through initiatives such as increasing product yield, reducing pressure loss using packed towers and improving compressor performance, we have managed to reduce specific power consumption (power consumed) by just over 20% over the course of the last 20 years. |

Air separation system for steel manufacturers |

Multifunctional film coating systems

| Kobe Steel has launched the W35 Series of compact sputter roll coaters designed to apply metal coatings to materials such as plastic films. W35 Series systems roll up plastic films and apply a continuous coating via processes such as chemical vapor deposition (CVD) and sputtering. With demand for barrier film systems used in manufacturing processes likely to increase in the future in line with the commercial development of organic EL and other new energy-saving displays, the W35 Series is expected to serve as an essential testing system for the purposes of research into manufacturing processes. |

W35 Series sputter roll coater |

Shinko Bolt, Ltd.

Major orders for large-diameter bolts for wind power generation facilities

| Shinko Bolt has developed and obtained certification from the Minister of Land, Infrastructure and Transport for large-diameter bolts that are strong enough to be used in large-scale structures as part of wind power generation facilities. During fiscal 2009, Shinko Bolt received orders for approximately 140 metric tons of large diameter bolts for wind power generation facilities. The large-diameter high-tension bolts and other galvanized high-strength bolts in question are due to be used at around 50 wind power generation facilities. |

Large-diameter high-tension bolts |

Kobelco Eco-Solutions Co., Ltd.

Trial project launched for using biogas as city gas

| In conjunction with the city of Kobe and Osaka Gas, Kobelco Eco-Solutions is working on a trial project aimed at using biogas produced at the Higashinada Sewage Treatment Plant in Kobe as municipal gas, under the name "Kobe Biogas". This will be the first time that anyone in Japan has tried to supply biogas, which is produced from sewage sludge purified to municipal gas specifications, directly via city gas pipes. Kobelco Eco-Solutions intends to examine operational procedures and economic viability through this project in an effort to promote similar projects and to help harness biogas resources more effectively. |

Bio-natural gas conversion facilities |

Kobelco Eco-Solutions Co., Ltd.

PCB detoxification facilities (plasma melting)

| We have completed construction of a PCB (polychlorinated biphenyl) treatment facility (phase 2) for the Japan Environmental Safety Corporation (JESCO) at its Kitakyushu Facility. Developed by Kobelco Eco-Solutions Co., Ltd. in conjunction with Nippon Steel Engineering Co., Ltd. the technology used at the facility is capable of simultaneously treating a wide range of PCB contaminated materials regardless of their shape or properties, including small electronic devices (fluorescent and mercury lamp ballasts, low voltage transformers and capacitors, etc.), sludge containing PCB and fabric or pressure sensitive copying paper soaked with PCB. PCB is broken down and detoxified inside a furnace, which is kept at a high temperature by combining the effects of high temperature plasma (at least 15,000?C) produced using electric energy with a molten bath (at least 1,400?C). |

|

Photos courtesy of JESCO |

|

Kobelco Eco-Solutions Co., Ltd.

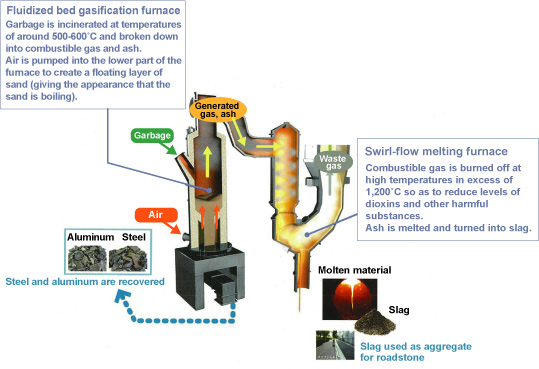

Fluidized Bed Gasification and Melting Furnace

| Construction completed on one of Japan's largest facilities Having worked on the project for four years since fiscal 2006, we have now completed construction of the Minami Refuse Incineration Plant and handed control over to Sagamihara City. The plant is a household waste treatment facility equipped with a fluidized bed gasification and melting furnace. Features (1) Largest capacity facilities in Japan The plant is equipped with a fluidized bed gasification and melting furnace designed to handle 525 metric tons of household waste per day, making it the largest facilities of its kind in Japan. (2) Reduced CO2 emissions through high efficiency power generation Equipped with a high-temperature, high-pressure boiler and a low-temperature economizer, the plant, with some of the highest standards in Japan, achieves higher levels of power generation efficiency. (3) Promoting recycling and environmental conservation The plant also handles incinerated ash from Sagamihara City's Kita Refuse Incineration Plant.The ash is melted, reduced in volume and detoxified, in an effort to promote recycling and reduce the volume of waste sent to landfill. |

Sagamihara City Minami Refuse Incineration Plant |

|

Fusion between fluidized bed gasification furnace + swirl-flow melting furnace = Fluidized bed gasification and melting furnace

Shinko Kenzai, Ltd.

Development of sound-absorbing partition panels in conjunction with partition manufacturer

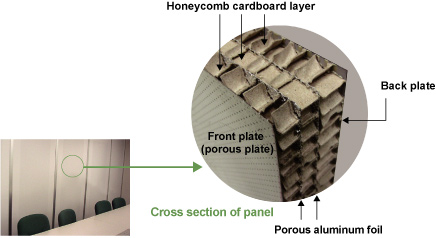

| In conjunction with leading partition manufacturer Comany, Shinko Kenzai, Ltd. has developed Q-PANE high-performance sound absorbing partition panels, applying a microporous sound absorption technology. With porous aluminum foil for increased sound absorption performance, the partition panels are the first of their kind in Japan and make it possible to create pleasant sound environments, by protecting privacy in medical institutions for example or improving working conditions in offices and factories. Q-PANE consists of a combination of porous aluminum foil and colored steel sheet around a honeycomb cardboard core. Despite being the same thickness as standard partition panels, their superior sound absorption capabilities enable Q-PANE to regulate indoor sound reverberation to create quieter, more pleasant environments. Shinko Kenzai and Comany are now planning to work together on sales promotion activities. |

|

* Some panels feature two honeycomb cardboard layers and one aluminum foil. |

Shinko Engineering & Maintenance Co., Ltd.

CO-PSA carbon monoxide separation and recovery systems

| CO-PSA systems use chemical absorbents to recover high purity carbon monoxide (CO) from mixed gases made up of hydrogen, CO, nitrogen, carbon dioxide and other elements. Shinko Engineering & Maintenance Co., Ltd. provides users with the best possible process depending on the required scale, gas source, product CO purity and purpose. Systems are characterized by the fact that high purity CO is separated and recovered via a single stage process and by their ability to easily recover high purity CO from mixed gases thanks to unique operating patterns and continuous fully automatic operation. They also help prevent global warming by increasing the amount of gas that can be used effectively. Through the application of CO-PSA technology, we have also developed the first PSA* process in Japan to separate and recover ethylene and propylene in raw gas form from mixed gases emitted by chemical plants. Whereas mixed gases are currently burnt off or used as boiler fuel, the ability to harness added value through the recovery of high purity gases will help significantly reduce environmental impact. * PSA: Pressure swing adsorption |

Commercial CO-PSA plant (Kakogawa Works) Product CO flow: 150Nm3/hour |

|

Kobelco Construction Machinery Co., Ltd.

Development and launch of a hybrid hydraulic excavator capable of reducing fuel

consumption by 40%

| Having already managed to reduce fuel consumption by 20% compared to conventional machines in the 20-ton class, Kobelco Construction Machinery Co., Ltd. has now developed the SK80 Hybrid hydraulic excavator, a machine capable of reducing fuel consumption by 40% even compared to conventional seven-ton machines. By continuing to supply hybrid technology that boasts such outstanding levels of fuel consumption, we intend to firmly establish the reputation that Kobelco is synonymous with fuel efficiency. In the run-up to the launch of the new SK80 Hybrid hydraulic excavator, Kobelco Construction Machinery has focused preparations on its outstanding levels of fuel consumption and the fact that the SK80 Hybrid will play a key role in residential areas so that people can really appreciate the results. As a piece of urban construction machinery, we have total confidence that the SK80 Hybrid will reduce CO2 emissions and keep noise levels to an absolute minimum. |

SK80 Hybrid hydraulic excavator |

|

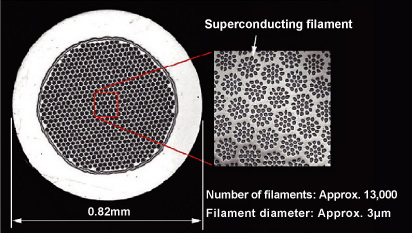

Japan Superconductor Technology, Inc.

Nb3Sn superconducting wire for the International Thermonuclear Experimental Reactor (ITER)

| More and more research is being carried out into the use of fusion energy in order to cater to growing worldwide energy demand safely and securely. The International Thermonuclear Experimental Reactor (ITER) is an international project that is aimed at demonstrating that it is possible to use nuclear fusion to generate power and gathering the necessary technical data to design and operate an actual power plant. To control fusion reactions, the ITER requires a number of superconducting magnets, of which one of the key materials is Nb3Sn superconducting wire. Of the 540 metric tons of Nb3Sn superconducting wire required in the ITER plans, 225 metric tons is due to be manufactured in Japan, with Nb3Sn superconducting wire produced by Japan Super Conductor Technology, Inc. set to also play a role. |

Nb3Sn superconducting wire for the ITER |

|