Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2010 > Disaster Prevention Activities

Disaster Prevention Activities

Disaster Prevention Activities

| With the company-wide organization and structure, we further upgrade our activities aiming to prepare for natural disasters and eliminate accidents. |

|

Fiscal 2009 Company-Wide Disaster Prevention Management Policy

|

Initiatives in Fiscal 2009

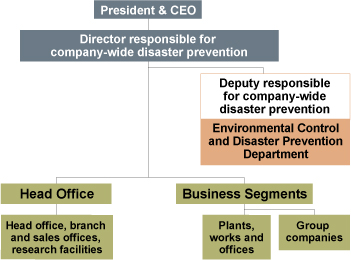

| Under the supervision of the President and the Director responsible for company-wide disaster prevention, we continue to implement disaster prevention management activities throughout the Kobe Steel Group based on the organizational structure outlined below. During fiscal 2009, we focused on the following three priorities and implemented a range of disaster prevention management activities in accordance with our Company-Wide Disaster Prevention Management Policy. |

Main priorities

|

Company-Wide Disaster Prevention Management Structure

Disaster Management in Times of Emergency

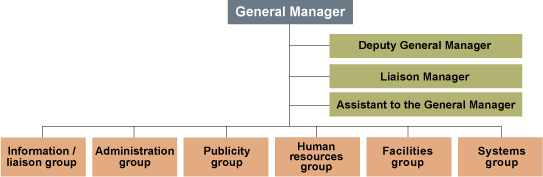

| In the event of a large-scale earthquake or other natural disaster or accident, a Disaster Management Headquarters will be set up to conduct relief work and restoration activities. In this event, we will also use emergency contact information on the Kobe Steel Group website to share emergency information, news regarding employees' safety and other important details, directly from affected companies. |

Organization Chart for Disaster Management Headquarters

| * The General Manager of the Disaster Management Headquarters is the President of Kobe Steel. The President appoints the Deputy General Manager of the Disaster Management Headquarters. |

|

Disaster Prevention Inspections

| In addition to existing site-specific disaster prevention activities, we have also introduced disaster prevention inspections at individual sites, carried out by the Environmental Control and Disaster Prevention Department from Head Office, with the aim of verifying details such as levels of compliance with disaster-related legislation. As a result of this year's inspections, we found no violations of any applicable laws. We will continue to reinforce our disaster prevention management structure through disaster prevention inspections in the future, focusing on areas such as legal compliance and risk avoidance at individual sites. |

The Environmental Control and Disaster Prevention Department carrying out a disaster prevention inspection (Ibaraki Plant) |

Earthquake Early Warning System

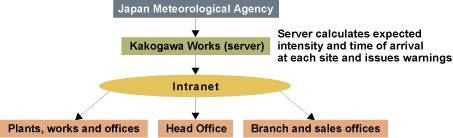

| At Kobe Steel, we are working to introduce an earthquake early warning system in order to keep the human and physical impact in the event of a large-scale earthquake to a minimum at our plants and works, head office, branch offices and sales offices. In response to alerts issued by the Japan Meteorological Agency, we calculate the expected intensity and time of arrival at each of our sites via an internal server at the Kakogawa Works and issue simultaneous earthquake early warnings to all locations that are expected to experience an earthquake above a certain scale. Initiatives such as these enable us to provide advance warning. We will continue to enhance our ability to prevent disasters in the future via initiatives such as emergency response drills based on earthquake early warnings. |

Outline of the Earthquake Early Warning System

Disaster Prevention Measures at Plants, Works and Offices

| Despite striving to prevent accidents, we were unable to completely eliminate fires and other accidents during fiscal 2009. We have nonetheless investigated the relevant causes and are taking appropriate action. We will make every effort to prevent such accidents or similar accidents from reoccurring in the future. |

Accidents and Incidents at Manufacturing Locations in FY2009

|

| * After a string of fires at the Takasago Works, we are in the process of removing flammable materials and conducting comprehensive inspections to prevent any reoccurrences, whilst also compiling documentation and establishing practices aimed at eliminating risks and preventing accidents from occurring in the future. |

Main Incidents in Fiscal 2009

|

Emergency drill at sites

| The area in which Kobe Steel and Shinko Kobe Power Station (Shinko Kobe Power) are located is designated as a special disaster prevention zone containing petrochemical complexes (Kobe district). As petrochemical complexes handle large quantities of substances such as oil and high-pressure gas, they are required to have their own in-house firefighting unit and are subject to other obligations such as maintaining disaster prevention equipment. They are also required to implement comprehensive disaster prevention measures in accordance with the Fire Service Act and other legislation. Via a committee made up of the nine companies located in the Kobe district, we organize comprehensive emergency drills every year in conjunction with the Kobe City Fire Department. In fiscal 2009, we organized an emergency drill at Kobe Steel in June. The drill involved three fire trucks and around 30 members of staff from Kobe Steel and other committee members, as well as ten fire trucks and around 30 firefighters from the Nada and Chuo Fire Departments. Based on the premise that a fire had broken out in an external tank containing hazardous materials and had to be prevented from spreading to the coal silo, the drill effectively demonstrated the committee's high level of disaster prevention awareness. |

Firefighting activities on the site of an external tank containing hazardous materials  Practicing emergency care for injured victims  Spraying cold water onto the coal silo |

Group Disaster Prevention Meeting

| The Kobe Steel Group holds an annual Group Disaster Prevention Meeting that is attended by representatives from Kobe Steel's works, plants and offices and Group companies. These meetings give disaster prevention managers an opportunity to share information and find lateral applications for their knowledge. The meeting held in November, 2009 was attended by 119 people from 63 Group companies. In addition to an outline of medium-term disaster prevention plans and a report on disaster prevention activities at individual sites courtesy of the secretariat, the meeting also featured a special presentation by Professor Kimiro Meguro from the University of Tokyo. |

Group Disaster Prevention Meeting in November 2009 |

TopicsKobelco 1/17 Walk

|

|||||||