Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2010

Energy-saving "Only One" technology designed to increase efficiency and utilize untapped energy

From compressors pumping out compressed air to compact generators to heat pumps, an essential component of large-scale air conditioning systems... The Kobe Steel Group's Only One products are designed to offer plants and industrial facilities outstanding efficiency and energy-saving performance in the industrial machinery sector.

They also make a major contribution to reducing energy consumption and CO2 emissions.

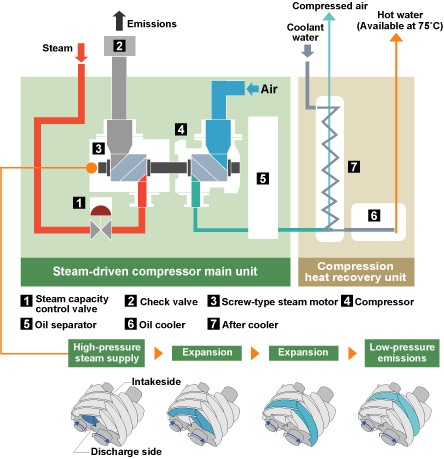

Outline of the screw-type steam motor-powered Kobelion® SD

Efforts with compressors that consume approximately 30% of industrial power

Compressors, which are used as utility systems by all industries, are known to be "power-guzzlers" that consume a huge amount of electricity. Compressors consume 25% to 30% of overall electric power volume at a typical Japanese factory.

To improve upon this, the Kobe Steel Group focused its accumulated machinery and engineering technologies and developed the KOBELIONTM, a standard compressor that realizes a significant reduction in energy consumption. Having become a mainstay product, the KOBELIONTM-VS/VX series maximizes the inverter control range to curb wasted power consumption.

Responding to various load fluctuations, this product realizes low-energy operation that cuts power consumption by approximately 40%.

KobelionR SD screw compressors are powered by screw-type steam motors, which effectively harness steam produced by boilers rather than using electricity, also reduce annual CO2 emissions by approximately 90% compared with conventional electric compressors.

Utilization of untapped steam energy spreads

SteamStar®, our range of compact screw-type steam generators, is another technology developed by the Kobe Steel Group that effectively harnesses steam, an underutilized energy source.

SteamStar® utilizes steam emitted from compact boilers used in small- to mid-sized manufacturing facilities to enable highly efficient power generation. Compared to the 30% to 40% power generation efficiency of traditional turbine-type power generators, SteamStar® realizes efficiency of 60%, the world's highest. If 10% of the approximately 250,000 small boilers in Japan were SteamStar®, it has been calculated that 5 million metric tons of CO2 emissions could be cut annually.

The industry's most energy-efficient water-cooled screw chiller

In the field of water-cooled screw chillers, Kobe Steel has developed the High Efficiency Mini series that realizes high energy efficiency. The main product in the lineup, High Efficiency Mini II, achieves the highest ranked energy efficiency of COP6.0-six units of heat energy are removed for every one unit of energy consumed-to realize a 70% cut in CO2 emissions over a year.

Here at the Kobe Steel Group, we will continue to push ahead with the development of technology based on the principle "environmental = performance" in an effort to contribute to the creation of a low-carbon society through energy-saving industrial machinery.

Remarks from the Key Technologist

Developing new products with the aim of harnessing renewable energy

Masayoshi Matsumura, General Manager

Technical Development Department,

Development Center,

Machinery Business

We are currently developing products that are designed to promote the use of renewable energy in the industrial machinery sector. In particular, we are working on the development of products such as binary generators and solar thermal generation systems in an effort to strike a balance between high performance and low cost and make a difference in terms of effectively harnessing geothermal heat, solar heat and general industrial exhaust heat.

Easy to use, environmentally friendly hydraulic excavators that improve fuel efficiency by an average of 20%

CO2 emissions reduction effect from construction machinery Launched in 2006 by Kobelco Construction Machinery Co., Ltd., the ACERA GEOSPEC hydraulic excavator complies with Tier III regulations that control NOX and hydrocarbon emissions and has improved fuel efficiency by 20% compared with conventional machinery. ACERA GEOSPEC significantly cuts operational noise and vibration while offering advanced features that consider both the environment and people. On a factory delivery basis, approximately 50,000 units of this model have been sold both in Japan and overseas. In fiscal 2009, ACERA GEOSPEC contributed to CO2 emissions reductions of approximately 400,000 metric tons through improved fuel efficiency.

Kobelco Construction Machinery Co. Ltd. is currently developing technology such as hybrid excavators, in an effort to reduce CO2 emissions even further, and environmental recycling construction machinery. We will continue to role out our range of environmentally friendly construction machinery on a global scale.

Remarks from the Key Technologist

Developing hybrid excavators capable of improving fuel efficiency by 40%

Shigeaki Saito, General Manager

Engineering Manufacturing Division

Hydraulic Excavator Engineering Group

Kobelco Construction Machinery Co., Ltd.

Having carefully designed each individual product so as to minimize energy loss and carried out repeated simulations and tests on actual machines, we have taken steps to reduce emissions from our ACERA GEOSPEC range whilst also managing to achieve a 20% improvement in fuel efficiency. Using the same technology as a base, we have also launched a hybrid excavator that improves fuel efficiency by 40%.

The eco-friendly ACERA GEOSPEC hydraulic excavator