Robots and Electric Power Sources

System

Swing Frames Welding System: ARCMAN™-MP

- The four-robot system offers significant reduction in the welding cycle time.

- The arrowhead-pattern weaving mode provides good bead appearance in vertical welding, making it unnecessary to use a conventional positioner and workpiece-clamping jig.

- The laser sensor contributes to obtaining high quality weld beads, overcoming root gap variation.

Robot

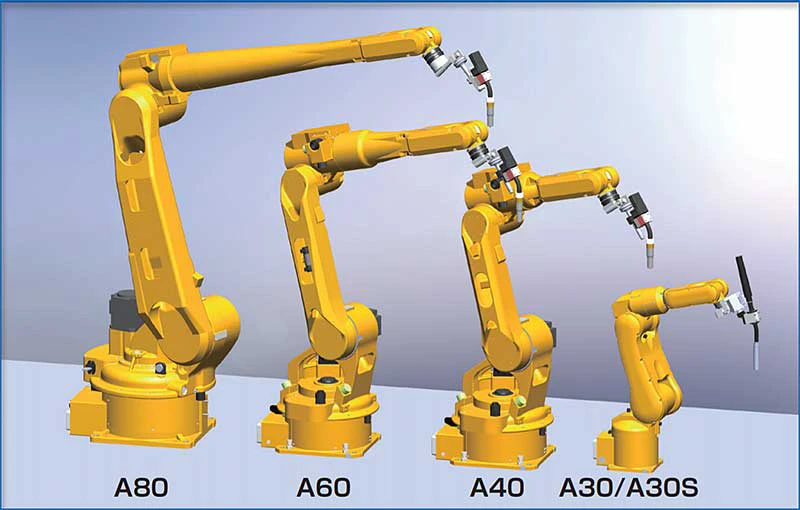

ARCMAN™ series Robot

- Four types of robot from large to ultra small

- ARCMAN™ A40, A60 and A80 are suitable for midium to thick plate welding with improved cable management

| Payload | Maximum reach | |

|---|---|---|

| ARCMAN™ A80 | 10kg | 2735mm |

| ARCMAN™ A60 | 10kg | 1646mm |

| ARCMAN™ A40 | 8kg | 1258mm |

| ARCMAN™ A30/A30S | 5kg | 858mm |

Power Sources

SENSARC™ RA500 (Designed for ARCMAN™ series)

- High-end welding power source for high productivity welding process

-

- Upgrade performance and function from conventional machine

- Achieve time saving in the welding process with stable low-spatter welding

- Excellent arc stability with new output control

- Maintenance friendly

Software for ARCMAN™ Welding System

- Offline teacing system

- Production support system