MIDREX® Process

MIDREX® Process

What is the MIDREX® Process?

- The direct reduced iron (DRI) is an ironmaking process alternative to a blast furnace. It uses hydrogen-rich reducing gas produced by reforming natural gas or hydrogen itself as the reducing gas to directly reduce iron ore.

- Since direct reduction ironmaking does not require coke or large-scale facilities like blast furnaces, DRI plants have been typically built in natural gas-producing countries. In recent years, there has been a rise in demand for DRI as a clean iron source to replace scrap and as an ironmaking process with low CO2 emissions.

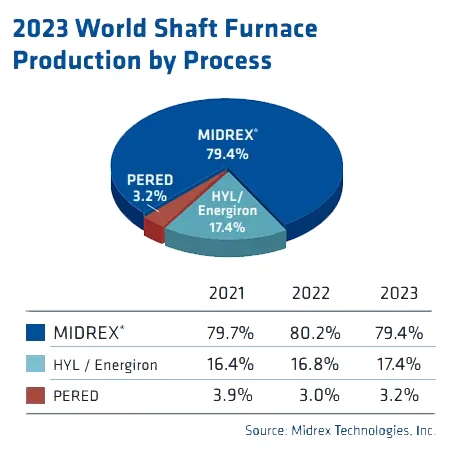

- Kobe Steel owns the license for the MIDREX® Process, which has approximately 80% of the global market share in gas-based direct reduction ironmaking. We are expanding our business globally in collaboration with Midrex Technologies (Kobe Steel's wholly owned subsidiary).

- The MIDREX process lineup comprises MIDREX Flex™, which allows for the flexible replacement of the reducing agent from natural gas to 100% hydrogen, and MIDREX H2™, which uses 100% hydrogen as the reducing gas, in addition to the conventional MIDREX Process. We offer solutions suited to our customers' demands at various phases of the energy transition to hydrogen.

MIDREX NG™

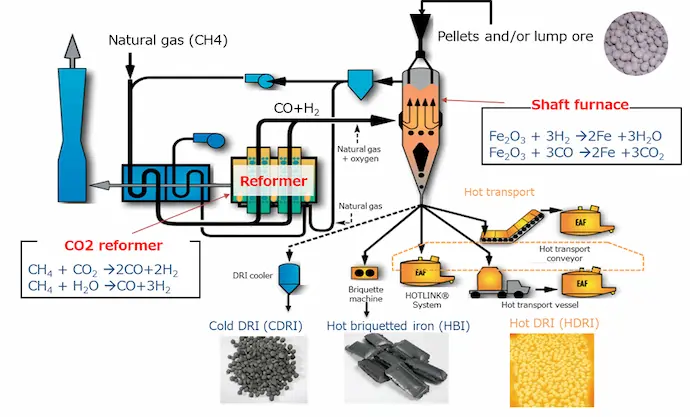

MIDREX NG™ uses natural gas as reductant to produce DRI from iron ore.

- The competitive edge of the MIDREX Process lies in two key elements : a shaft furnace that reduces iron ore and a reformer that reforms natural gas to hydrogen-rich reducing gas.The recycling of the top exhaust gas from the shaft furnace is a key component of the process, facilitating the efficient utilization of natural gas. This is an eco-friendly process with reduced fuel consumption.

- A wide variety of lump ores and iron ore pellets can be used as raw materials.

- The MIDREX® Process produces not only hot DRI (HDRI) and cold DRI (CDRI), but also hot briquetted iron (HBI), which is less susceptible to reoxidation and suited for long-distance transportation. Its market share accounts for approximately 90% of HBI production.

- An HDRI plant uses HOTLINK® System and conveyors to deliver hot DRI directly into the electric arc furnace while maintaining a high temperature, enabling energy savings and increased output.

- Low-pressure operation (easy operation)

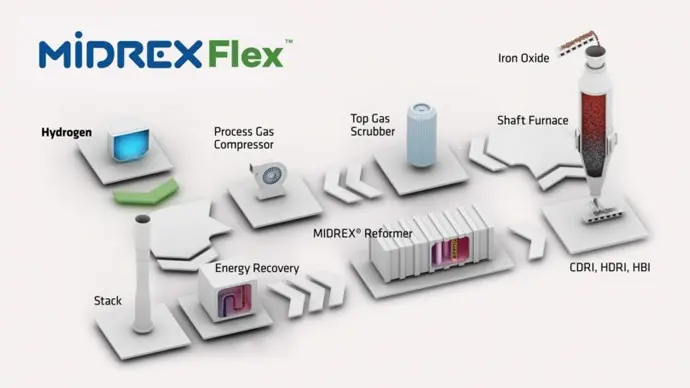

MIDREX Flex™

MIDREX Flex™ is a process that allows for the flexible replacement of the reducing agent from natural gas to hydrogen in the range of 0% to 100%.

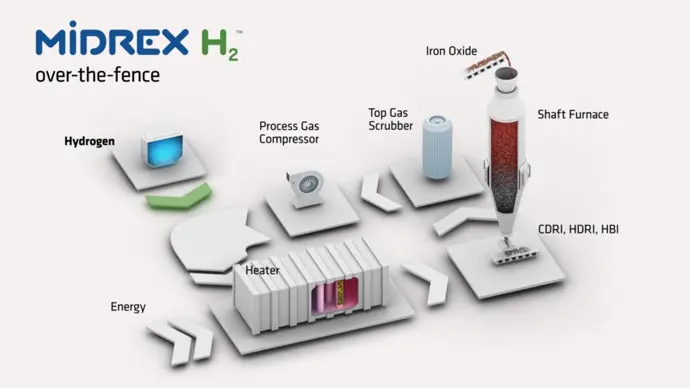

MIDREX H2™

MIDREX H2™ uses 100% hydrogen as reductant. This process employes an electric heater to heat the reducing gas (hydrogen), instead of the reformer to process natural gas.

MIDREX® Direct Reduction Plants Around the World

Since 1969, we have delivered over 90 plants to 21 countries around the world. (As of December 2024)

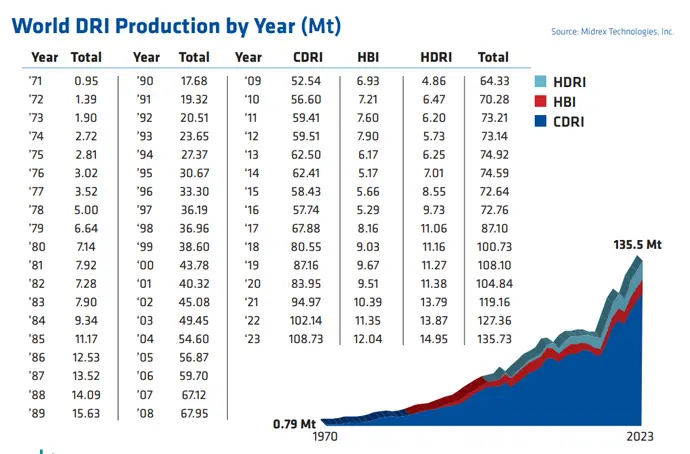

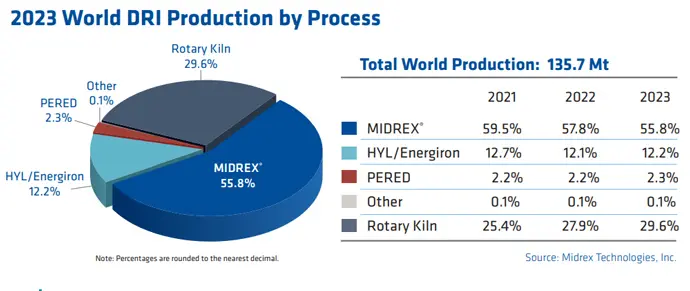

Global DRI Production (as of the end of 2023)

Global market share of direct reduction steelmaking processes

Midrex Technologies, Inc.

| Company name | Midrex Technologies, Inc. (USA, A wholly owned subsidiary of Kobe Steel, Ltd) |

|---|---|

| Location | 3735 Glen Lake Drive, Suite 400 Charlotte, North Carolina 28208 USA Phone: +1-704-373-1600, Email: info@midrex.com |

| Business Description |

|

| Website |

Contact Us

You can reach us by clicking the inquiry button.