Construction Machinery

Construction machinery creates infrustructure all over the world. KOBELCO provides welding process, system, and materials which contributes high quality and productivity.

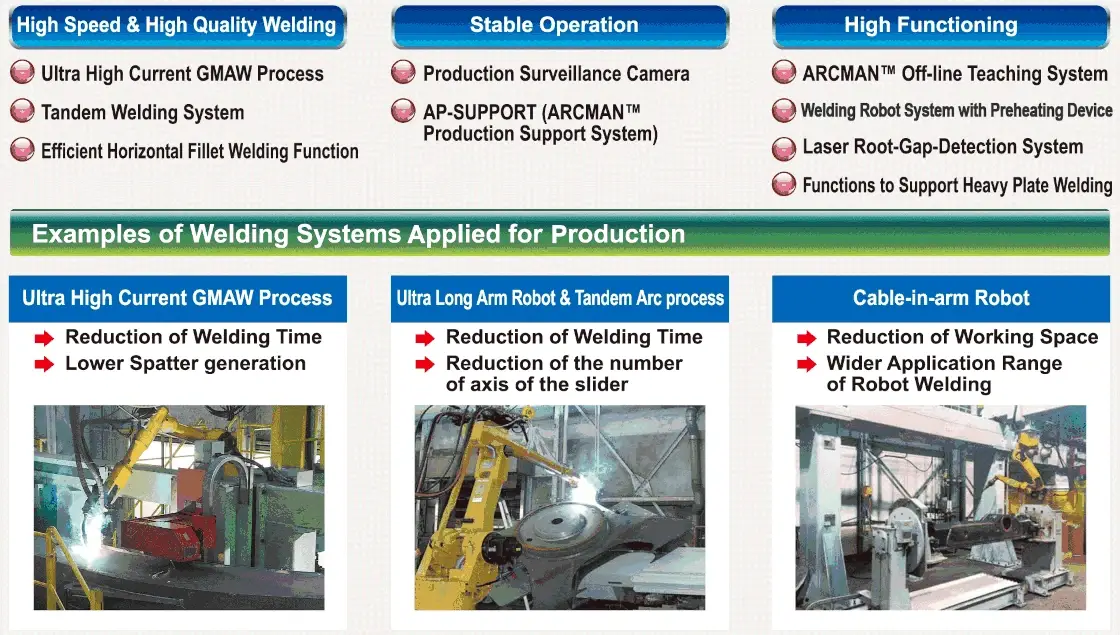

- Welding Solutions to Achieve High Quality & High Speed Automation

- Ultra High Current GMAW welding process

- Ultra High Current GMAW welding process (Approx. 2 minutes)

- Ultra-high current GMAW welding process provides high efficiency

- Spray arc provides low spatter, even at high current

- Deep Penetration

- Typical Welding Joint

- Features of Ultra High Current GMAW welding Process / the Tandem MAG welding process

- Configuration of ultra high current GMAW process

- Tandem Arc Welding System

- Efficient Horizontal Fillet Welding with CB controller

- Laser Root-Gap Detection System

- Welding Robot System with Preheating Device

- AP-SUPPORT™

Welding Solutions to Achieve High Quality & High Speed Automation

KOBELCO offers welding solutions package, original welding process integrated with welding robot system and welding consumables

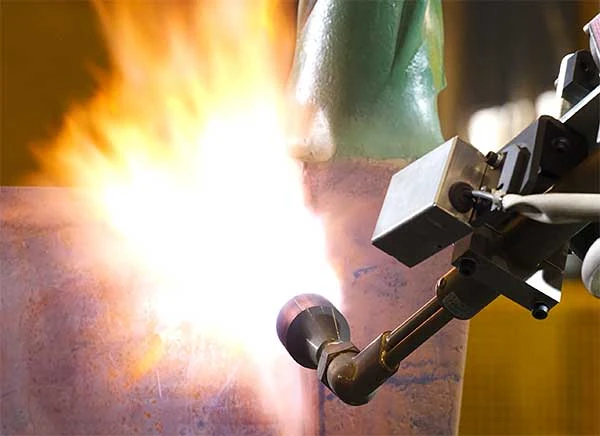

Ultra High Current GMAW welding process

Ultra High Current GMAW welding process (Approx. 2 minutes)

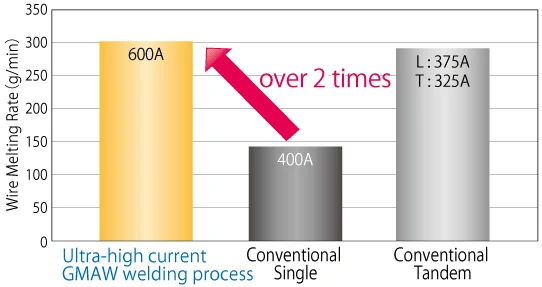

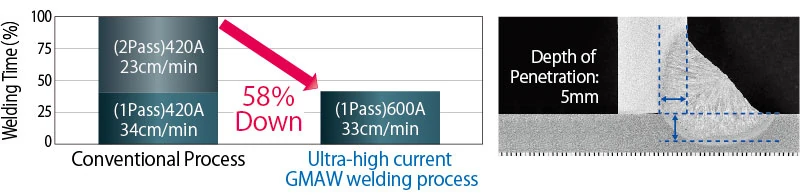

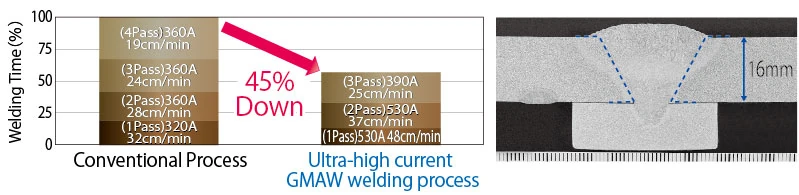

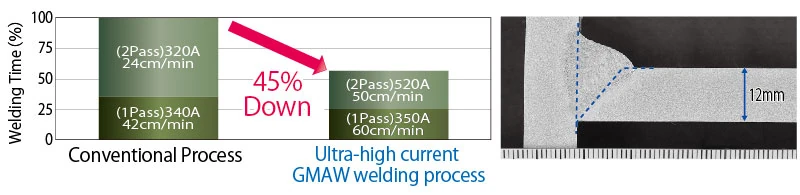

Ultra-high current GMAW welding process provides high efficiency

Ultra-high current MAG welding process provides high efficiency. Double productivity of conventional single arc, and same as tandem arc process.

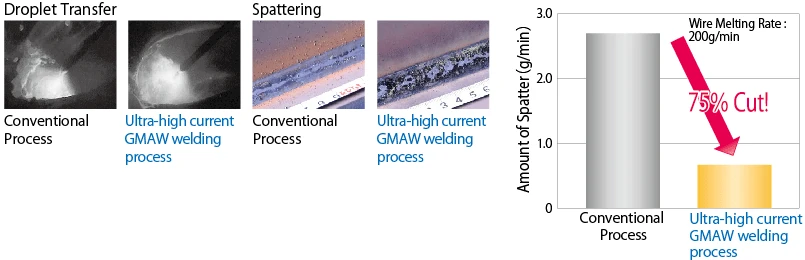

Spray arc provides low spatter, even at high current

Low spatter and stable arc has been achieved with Ultra high current GMAW process and MX-A100D specially designed for this process.

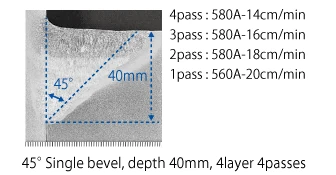

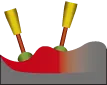

Deep Penetration

Obtain deeper penetration than conventional process.

Ultra High Current GMAW welding process

Depth of Penetration: 5.0mm

Welding Current: 600A

Welding Speed: 33cm/min

Conventional / Tandem Arc Process

Depth of Penetration: 2.5mm

Welding Current:

L 350A T 320A

Welding Speed:

1pass 55cm/min

2pass 40cm/min

- *Flat-Fillet (Leg Length: 15mm)

Typical Welding Joint

1F, Leg length 15mm * Conventional Process = 100%

1G 50° V-groove, thickness 16mm, root gap=5mm

1G 45° Single bevel, thickness 12mm, root face 2mm

Features of Ultra High Current GMAW welding Process / the Tandem MAG welding process

Ultra High Current GMAW welding process, with single torch, promise wide application of robot welding with easy teaching and handling.

| Ultra High Current GMAW welding process* | Tandem MAG welding Process* | |

|---|---|---|

| Deposition rate | Better | Better |

| Spatter generation | Better | Fair |

| Welding speed | Good | Better |

| Penetration | Better | Fair |

| Handling | Better | Fair |

| Gas Cost | Better | Fair |

Configuration of ultra high current GMAW process

- Welding Robot ARCMAN™ MP

- Welding wire FAMILIARC™ MX-A100D 1.4mmΦ

- Welding Power Source SENSARC™ AB500

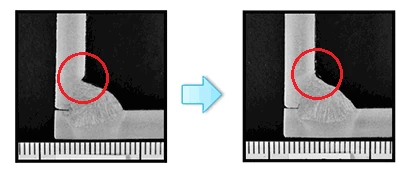

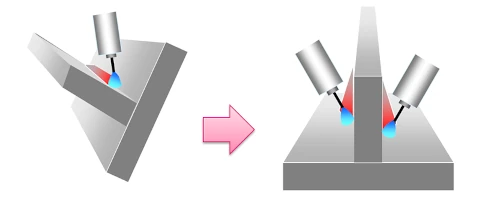

Tandem Arc Welding System

Features

- Tandem welding reduces the cycle time by about 40% compared to single welding.

- Advanced Lord Characteristic Control and Synchronous Amplitude Modulation Control function ensures stable arc and lower spatter welding.

- Dual Arc Sensor detects the difference in the amperage of the leading and the trailing wire and adjusts the alightment of the leading wire as well as correct the misalignment of the trailing wire during welding. This function significantly improves the welding quality and reduces the need for repair welding.

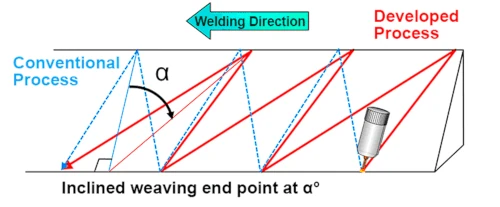

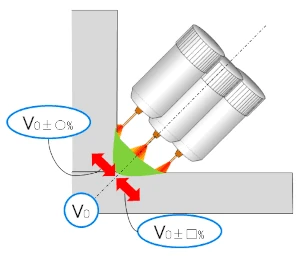

Efficient Horizontal Fillet Welding with CB controller

Features

- Able to achieve high speed horizontal fillet welding with single arc, 6mm leg length at 700mm/min, without undercuts and overlaps.

Able to simplify positioner by changing welding position from Flat positon to Horizontal Fillet position.

Function

- Setting arc voltage at vertical and flat member sides independently

- Changing weaving direction

Cofigulation

- Manupilator: ARCMAN™ GS, ARCMAN™ MP

- Robot Controller: CB Controller

- Welding Power Source: SENSARC™AB500

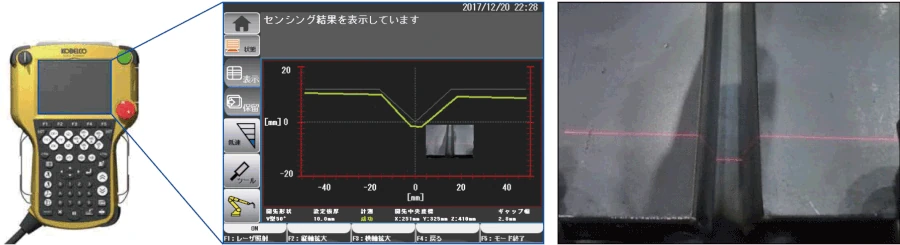

Laser Root-Gap Detection System

Features

- Able to apply various figures, even detect the root-gap at flare and T-joint

- Able to reduce detection time by around 60% comparing to wire touch sensing

- Able to detect more precisely than wire touch sensing

Welding Robot System with Preheating Device

It offers fully automatic preheating and welding;

- Switching between welding torch and preheating device

- Iginiting and fire extinguishment

- Detecting completion of preheating with sensor and proceed to welding

Visit our YouTube Channel and watch KOBELCO Welding Robot System with Preheating Device

AP-SUPPORT™

- Automatically records information such as operation

- Software program for productivity, weld quality, and cycle time improvement, with helping identify possible cause of stoppage operation

Contact Us

You can reach us by clicking the inquiry button.