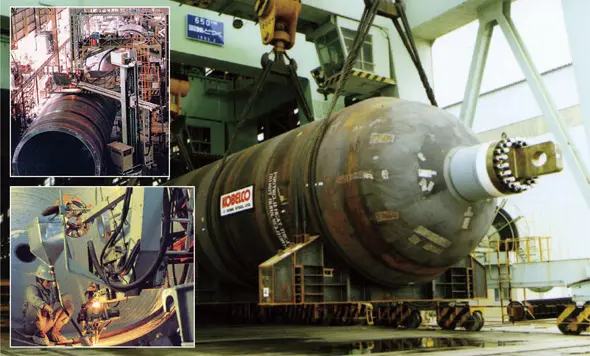

Reactor

Kobe Steel, as reactor manufacturer and welding expert, develop and provide high quality welding materials which meet the stringent requirement under high-temperature and high-pressure hydrogen environment.

Table of contents

Welding Consumables for Pressure Vessel

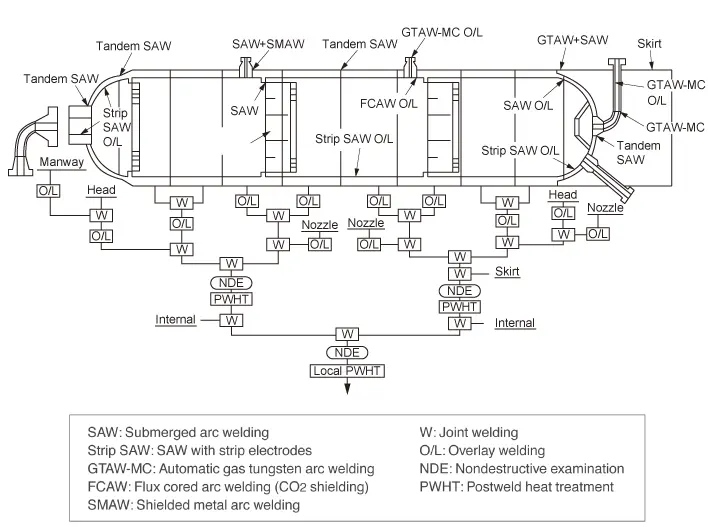

Welding Applied to Reactor

Welding Consumables for Reactor - Products and Features

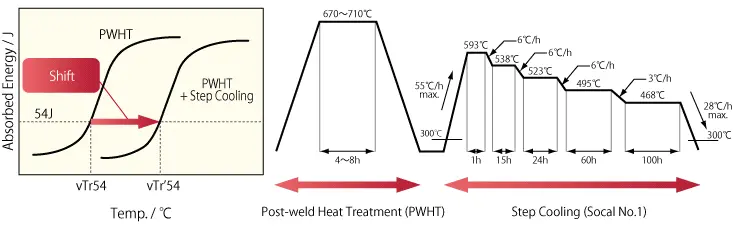

- *Measurement of temper embrittlement properties with step cooling

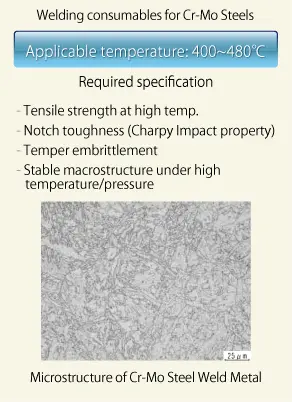

Welding Consumables for Cr-Mo Steel

| Type of Steel | Process | Porality | Product | ASME / AWS |

|---|---|---|---|---|

| 1.25Cr-0.5Mo | SAW | AC |

PF-200 /

US-511N

|

SFA / A5.23 F8P2-EG-B2 |

| SMAW | AC |

CM-A96MB

|

SFA / A5.5 E8016-B2 | |

| GTAW | DCEN | SFA / A5.28 ER80S-G | ||

| 2.25Cr-1Mo | SAW | AC |

PF-200 /

US-521S

|

SFA / A5.23 F9P2-EG-B3 |

| SMAW | AC | SFA / A5.5 E9016-B3 | ||

| GTAW | DCEN | SFA / A5.28 ER90S-G | ||

| 2.25Cr-1Mo-V | SAW | AC | SFA / A5.23 F9P2-EG-G (ASME Sec.Ⅷ Div.2) |

|

| SMAW | AC | SFA / A5.5 E9016-G (ASME Sec.Ⅷ Div.2) |

||

| GTAW | DCEN | SFA / A5.28 ER90S-G (ASME Sec.Ⅷ Div.2) |

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

Welding Consumables for Cr-Mo Steel and Mechanical Properties

| Product | PWHT | 0.2%YS MPa | T.S. MPa | EL.(4D)% | vE J |

|---|---|---|---|---|---|

|

PF-200 /

US-511N

|

680°C × 6h | 490 | 595 | 29 | 152 (-18°C) |

|

CM-A96MB

|

680°C × 6h | 479 | 582 | 29 | 152 (-18°C) |

| 680°C × 6h | 509 | 612 | 28 | 166 (-18°C) | |

|

PF-200 /

US-521S

|

690°C × 8h | 550 | 661 | 25 | 150 (-29°C) |

| 690°C × 8h | 512 | 653 | 28 | 166 (-29°C) | |

| 690°C × 8h | 538 | 677 | 26 | 244 (-29°C) | |

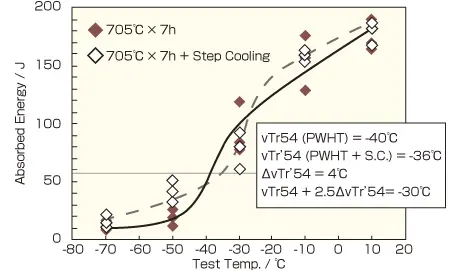

| 705°C × 7h | 620 | 710 | 26 | 83 (-29°C) | |

|

CM-A106H

|

705°C × 7h | 609 | 708 | 24 | 90 (-29°C) |

|

TG-S2CMH

|

705°C × 7h | 623 | 718 | 23 | 208 (-29°C) |

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

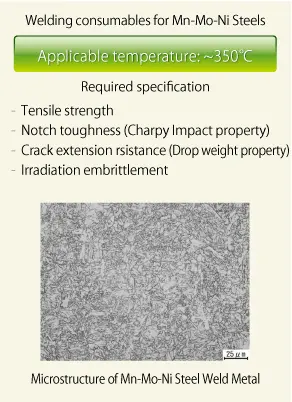

Welding Consumables for Mn-Mo-Ni Steel

| Type of Steel | Process | Porality | Product | ASME / AWS |

|---|---|---|---|---|

| 80ksi class Mn-Mo-Ni |

SAW | AC / DCEP |

PF-200 /

US-56B

|

– |

| SMAW | AC / DCEP |

BL-96

|

SFA / A5.5 E9016-G | |

| GTAW | DCEN |

TG-S56

|

SFA / A5.28 ER80S-G | |

| 90ksi class Mn-Mo-Ni |

SAW | AC / DCEP |

PF-200 /

US-63S

|

SFA / A5.23 F10P2-EG-G |

| SMAW | AC / DCEP |

BL-106

|

SFA / A5.5 E10016-G | |

| GTAW | DCEN |

TG-S63S

|

SFA / A5.28 ER90S-G |

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

Line-up as per Type of Steel / Process

SMAW

| Grade (Type of Steel) |

DCEP | AC | ||

|---|---|---|---|---|

| AWS Class. | Product | AWS Class. | Product | |

| Gr.11 (1.25Cr-0.5Mo) |

E8016-B2 | E8016-B2 |

CM-A96MB

|

|

| Gr.22 (2.25Cr-0.1Mo) |

E9015-B3 | – | – | |

| E9016-B3 | E9016-B3 |

CM-A106N

|

||

| Gr.22V (2.25Cr-1Mo-V) |

E9016-G | E9016-G |

CM-A106H

|

|

| Gr.5 (5Cr) |

E8018-B6 |

CM-5

|

E8018-B6 |

CM-5

|

| Gr.9 (9Cr) |

E8018-B8 |

CM-9

|

E8018-B8 |

CM-9

|

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

SAW

| Grade (Type of Steel) |

DCEP | AC | ||

|---|---|---|---|---|

| AWS Class. | Product | AWS Class. | Product | |

| Gr.11 (1.25Cr-0.5Mo) |

F8P2-EG-B2 | F8P2-EG-B2 |

PF-200 /

US-511N

|

|

| F8P2-EB2R-B2R | – | – | ||

| Gr.22 (2.25Cr-0.1Mo) |

F9P2-EG-B3 | F9P2-EG-B3 |

PF-200 /

US-521S

|

|

| Gr.22V (2.25Cr-1Mo-V) |

F9P2-EG-G | – |

PF-500 /

US-521H

|

|

| Gr.5 (5Cr) |

– | – | F7P2-EG-B6 |

PF-200S /

US-502

|

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

GMAW and GTAW

| Grade (Type of Steel) |

AWS Class. | Product | |

|---|---|---|---|

| GMAW | GTAW | ||

| Gr.11 (1.25Cr-0.5Mo) |

ER80S-G |

MG-S1CM

|

TG-S1CM

|

| Gr.22 (2.25Cr-0.5Mo) |

ER90S-G |

TG-S2CM

|

|

| Gr.22V (2.25Cr-1Mo-V) |

ER90S-G | – |

TG-S2CMH

|

| Gr.5 (5Cr) |

ER80S-B6 |

MG-S5CM

|

TG-S5CM

|

| Gr.9 (9Cr) |

ER80S-B8 |

MG-S9CM

|

TG-S9CM

|

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

Welding Consumables for Overlay Cladding

For corrosion resistance, Austenite stainless are overlayed on inner wall of reactor.

| Type of Steel | Base Metal Layer | SAW | ESW |

|---|---|---|---|

| SUS 308 | 1st |

PF-B1 / US-B309L

|

PF-B7FK / US-B309L

|

| 2nd |

PF-B1 / US-B308EL

|

PF-B7FK / US-B308EL

PF-B7FK / US-B308L

|

|

| SUS 316 | 1st | – |

PF-B7FK / US-B309L

|

| 2nd | – |

PF-B7FK / US-B316EL

|

|

| SUS 317 | 1st | – |

PF-B7FK / US-B309L

|

| 2nd | – |

PF-B7FK / US-B317L

|

|

| SUS 347 | 1st |

PF-B1FP / US-B347LP

|

PF-B7FK / US-B309LCb

|

| 2nd |

PF-B1FK / US-B347LD

|

PF-B7FK / US-B347LD

|

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

Chemical Composition of Overlaid Weld Metal

(%)

| Product | C | Si | Mn | P | S | Ni | Cr | Mo | Nb |

|---|---|---|---|---|---|---|---|---|---|

|

PF-B7FK /

US-B309L Base metal: A533-B-1 1layer |

0.01 | 0.51 | 1.4 | 0.02 | 0.01 | 10.6 | 20.8 | 0.05 | < 0.01 |

|

PF-B7FK /

US-B309LCb Base metal: A387-22 1layer |

0.02 | 0.53 | 1.5 | 0.02 | < 0.01 | 10.1 | 18.2 | 0.18 | 0.45 |

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

Contact Us

You can reach us by clicking the inquiry button.