Building Structure

Welding of structural steel is required for high quality to ensure earthquake resistance in Japan with many earthquakes. Kobe Steel will propose welding processes, materials and systems that achieve both higher quality welding and higher efficiency.

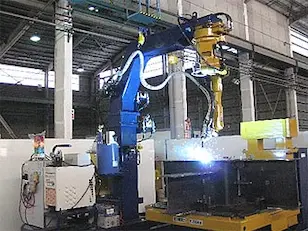

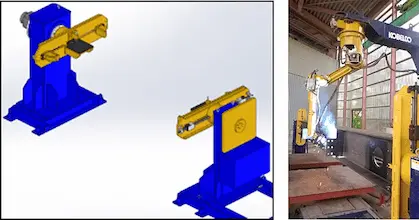

ARCMAN™ Welding Robot System and Welding Wire

ARCMAN™ Welding Robot System and Welding Wire

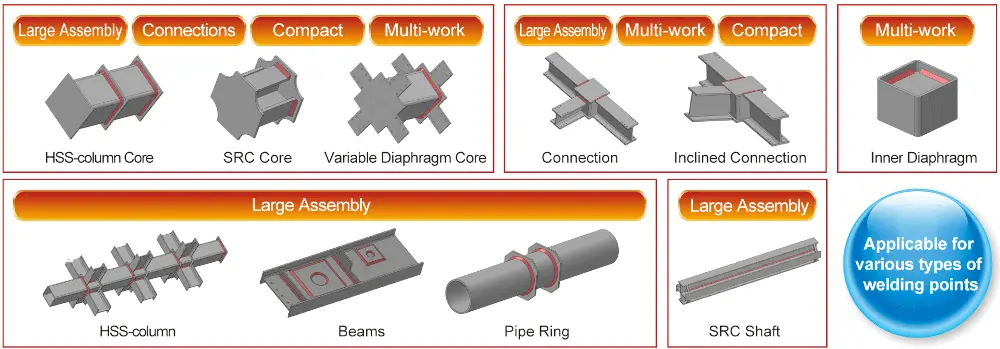

Line-ups of welding robot systems applicable for various type of welding points

| 490MPa TS Class | 550MPa class | 590MPa class | 690MPa class | |

|---|---|---|---|---|

| CO2 Welding |

MG-50R

MG-50R (N)

|

MG-50R

MG-56R

MG-56R (N)

|

MG-60

MG-60R (N)

|

MG-70

MG-70R (N)

|

| Ar-CO2/ Pulse-MAG welding |

MIX-50R

|

MIX-55R

|

MG-S63B

|

MG-S70

|

- * stands for FAMILIARC™, stands for TRUSTARC™

- *"R(N)"series-specially designed for REGARC™ Process / compatible with conventional constant voltage welding)

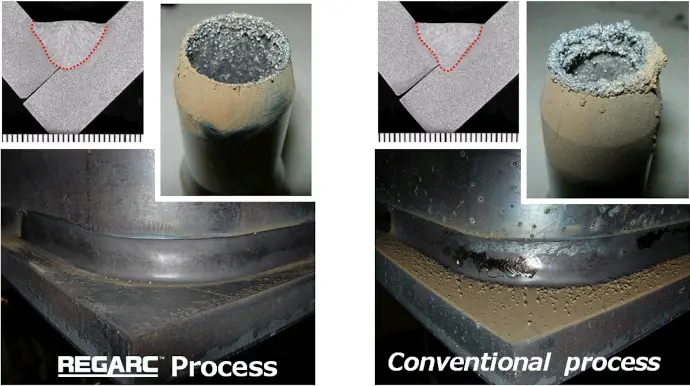

REGARC™ Process

- Achieves systenatic and smooth droplet transfer for global transfer through our original current / voltage wave form controller, and reduce production time with lower spatter generation

- REGARC™ Process can be equipped on Comact, Large assembly (2-arc), Core connection (2-Arc), Multi-work welding robot sysytem.

Comparison of State of Arc - Conventiocal CV and REGARC™ process

REGARC™ greatly reduces the amount of spatter adhensive to Torch Nozzle and Work

- Low spatter generation

- Low hume generation

- High deposition efficiency

- Deep penetration

Stable of spatter generation

Stable droplet transfer

REGARC™ Welding Robot System Installed

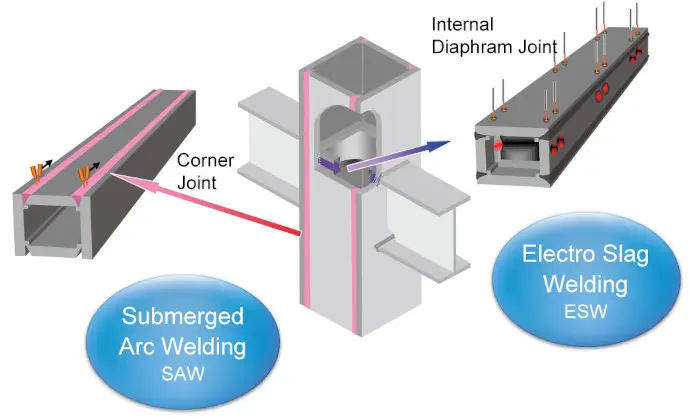

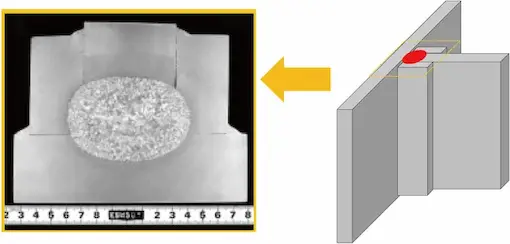

Welding of Box Column and Inner Diaphram

Submarged arc welding (SAW)

| Tensile strength of Base Metal (Yield Strength) | Carbon Steel | High HAZ Toughness Steel |

|---|---|---|

| 400MPa class (235MPa) | US-36L / PF-I53ES | — |

| 490MPa class (325MPa) | US-36L / PF-I53ES US-36L / PF-I55ES |

US-55ST / PF-I55ST |

| 520MPa class (355MPa) | US-36L / PF-I55ES US-49 / PF-I53ES |

|

| 550MPa class (385MPa) | US-36L / PF-I55ES US-49 / PF-I53ES |

US-60ST / PF-I60ST |

| 590MPa class (440MPa) | US-49 / PF-I53ES US-49 / PF-I55ES |

|

| 790MPa class (720MPa) | US-80LT / PF-H80AK (Only for multi-pass welding) |

— |

- * stands for FAMILIARC™, stands for TRUSTARC™

- Example of welding parameter

Plate Thickness: 50mm Wire: 6.4mm dia

L:1950A-38V-22cm/min

T:1450A-48V

Electroslag welding (ESW)

| Tensile Strength of Base Netal (Yield Strength) | Carbon Steel | High HAZ Toughness Steel |

|---|---|---|

| 400MPa class (235MPa) | ES-55 / EF-38 | — |

| 490MPa class (325MPa) | ES-55ST / EF-38 | |

| 520MPa class (355MPa) | — | |

| 550MPa class (385MPa) | — | ES-56ST / EF-38 |

| 590MPa class (440MPa) | — | ES-60ST / EF-38 |

- * stands for FAMILIARC™, stands for TRUSTARC™

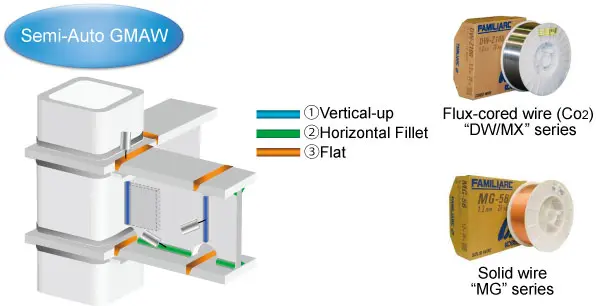

Site Welding of Beam to Column

Flux core wire (FCAW)

| 490MPa class | 550MPa class | 590MPa class | |

|---|---|---|---|

①Vertical up

|

|

DW-55

|

DW-60

|

②Horizontal fillet

|

|

MX-55F | MX-60F

|

③Flat

|

|

|

MX-60 |

- * stands for FAMILIARC™, stands for TRUSTARC™

- *MP for multi-pass welding, BF for single pass welding for large leg length

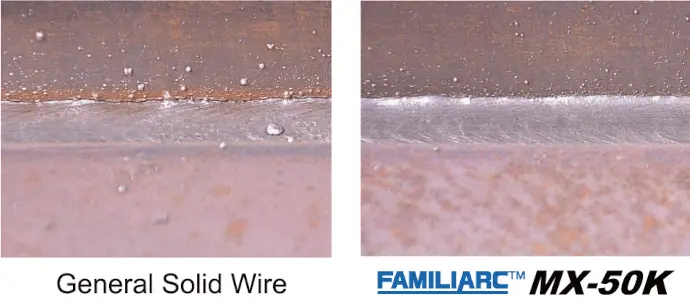

FAMILIARC™ MX-50K

JIS Z 3313 T 49J 0 T15-0 C A-U

- Excellent deep penetration as solid wire

- Superior high deposition rate / efficiency to that of solod wire

- Excellent arc stability

- Excellent slag removal

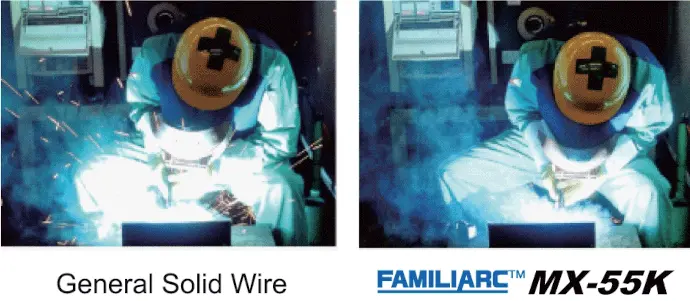

FAMILIARC™ MX-55K

JIS Z 3313 T 55 0 T15-0 C A-U

- Achieves high efficiency eelding

- Soft arc and less spatter generation

FAMILIARC™ MX-Z50F

JIS Z 3313 T 49J 0 T1-0 C A-U

- Smooth bead shape even at the toe of weld

- Excellent fitness of the bead even with steel plate covered with mill scale

- Excellent arc stability

- Excellent slag removal

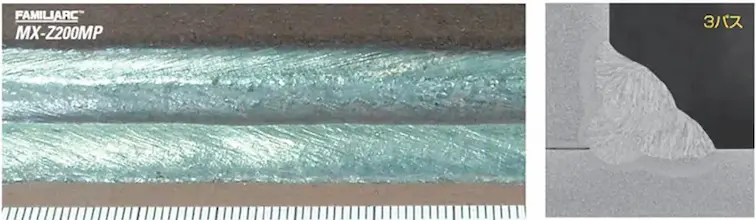

FAMILIARC™ MX-Z200MP

JIS Z 3313 T 49J 0 T1-0 C A-U

- Suitable for multi-pass horizontal fillet welding

- Excellent usability

- Excellent porosity resistance

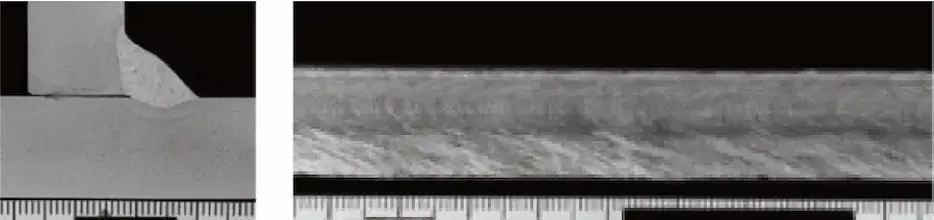

FAMILIARC™ DW-50BF

JIS Z 3313 T 49J 0 T1-0 C A-U

- Achieves big leg length (10mm max) even with single pass horizontal fillet welding

- Excellent bead appearance

- Excellent slag removal

- Low hume generation / low spatter generation

Solid wire

| 490MPa TS Class | 550MPa class | 590MPa class | 690, 780MPa class | For fire-resistant steel | |

|---|---|---|---|---|---|

③Flat

|

MG-50 | MG-55 | MG-60 | MG-70 | MG-490FR |

| MG-56 | MG-80 | MG-520FR | |||

| MG-82 |

- * stands for FAMILIARC™, stands for TRUSTARC™

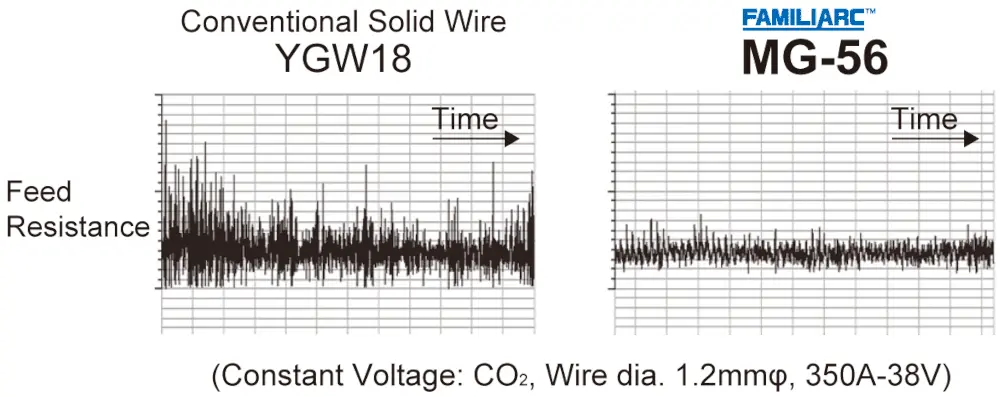

NEW FAMILIARC™ MG-56

JIS Z 3312 YGW18

- Excellent arc stability and wire feeding

- Excellent mechanical properties of weld metal

- Example of welding parameter

Plate thickness: : 60mm Wire dia.: 1.4mmΦ

Welding Current 250~300A

Position : Flat

Structural Beam Welding Robot System

- Applicable for wide range of welding points with specialized positioner and turn welding function

- Simple operation with specialized software for teaching

- FAMILIARC™ MX-Z200MP enables low spatter welding and beautiful bead shape

Visit our YouTube Channel and watch KOBELCO robot welding solutions, REGARC™ and various welding robot systems.

Welding Consumables for Galvanized Steel

Application

- Water pipe / Gas pipe

- Sound insulating-wall

- Light weight steel structure

- Parts of bus / Truck

- Solar panel suppot

Example-Application

Line-up of "1Z" series

| Welding Process | Trade name | Shielding Gas | Polarity | Recommended Zn Coating Mass (g/m2) |

|---|---|---|---|---|

| Solid wire | SE-1Z JIS Z 3312 G 49 A 0 C 12 |

CO2 | DC(+) | ≦100g/m2 |

| MG-1Z JIS Z 3312 G 49 A 0 C 12 |

CO2 | DC(+) | ≦100g/m2 | |

| Flux-cored Wire |

|

CO2 | DC(+) | ≦150g/m2 * Recommended for not kess than 200A |

| MX-100Z JIS Z 3313 T 49J 0 T15-1 C A-U |

CO2 | DC(+) | ≦150g/m2 * Recommended for equal or less than 200A |

|

|

CO2 | DC(-) | ≦550g/m2 | |

Self shield wire

|

— | DC(-) | ≦550g/m2 | |

| Stick Electrode |

|

— | AC DC(±) |

≦550g/m2 |

- *stands for FAMILIARC™

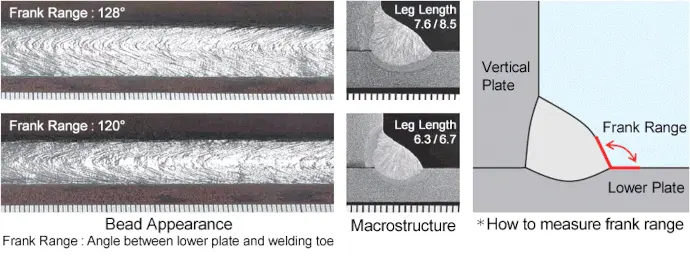

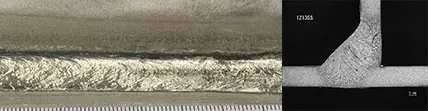

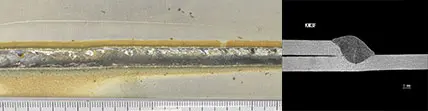

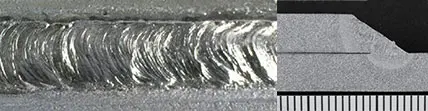

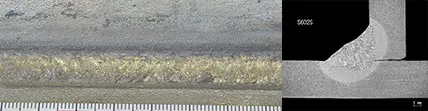

Example of Bead Appearance and Macrostructure

Recommended Zn Coating Mass: 90g/m2

FAMILIARC™ SE-1Z

- Horizontal fillet Plate thickness: 2.3mm、180A-22V-500mm/min.

- Wire dia.: 1.2mm、Gas CO2、DCEP

Recommended Zn Coating Mass: 135g/m2

FAMILIARC™ MX-1Z

- Horizontal fillet Plate thickness: 3.2mm、240A-30V-450mm/min.

- Wire dia.: 1.2mm、Gas CO2、DCEP

FAMILIARC™ MX-100Z

- Lap joint (Horizontal fillet) Plate thickness: 2.3mm、140A-19V-300mm/min.

- Wire dia.: 1.2mm、Gas CO2、DCEP

Recommended Zn Coating Mass: 450g/m2

FAMILIARC™ Z-1Z

- Horizontal fillet Plate thickness: 6.0mm、130A

- 3.2mm dia

FAMILIARC™ Z-1Z

- Lap joint (Horizontal fillet) Plate thickness: 6.0mm、130A

- 3.2mm dia

Recommended Zn Coating Mass: 550g/m2

FAMILIARC™ DW-1SZ

- Horizontal fillet Plate thickness: 6.0mm、240A-22V-250mm/min.

- Wire dia.: 1.4mm、Gas :CO2、DCEN

Contact Us

You can reach us by clicking the inquiry button.