Offshore Structures

KOBELCO has plenty supply record to all types of offshore structures.

Table of contents

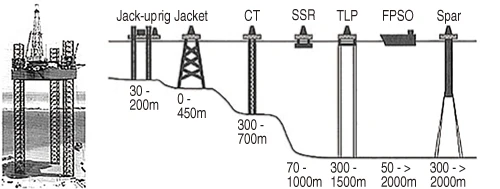

- Types of Offshore Structures / Operating Water Depth

- Jack-up Rig and Welding Materials

- TRUSTARC™ DW-55LSR/DW-A55LSR

FCAW with Unsurpassed Notch Toughness in AW/SR condition - TRUSTARC™ DW-A62LSR for 610MPa Class Steel

FCAW with Unsurpassed Notch Toughness in AW/SR condition - TRUSTARC™ DW-A61LSR for 610MPa Class Steel

FCAW with Unsurpassed Notch Toughness in AW/SR condition & Satisfying NACE MR0175 (Ni < 1.0%) - Welding Consumables for Duplex Stainless

- Welding Materials for Offshore Structures

Types of Offshore Structures / Operating Water Depth

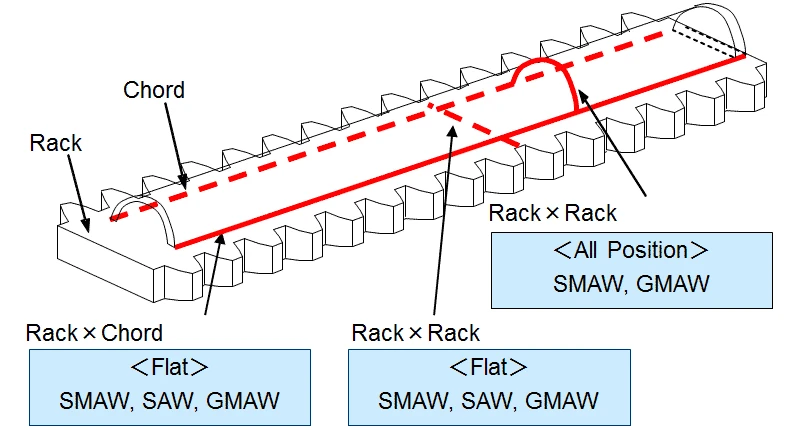

Jack-up Rig and Welding Materials

Typical Welding Process

Welding Consumables for 780 MPa Class Steel

| Process | Product | Specification | Absorbed energy / vEtemp. ≧47J |

Remark |

|---|---|---|---|---|

| SMAW |

LB-88LT

|

AWS A5.5 E11016-G JIS Z3211 E7816-N5M4 L |

-60 ℃ | Polarity:AC |

|

LB-80L

|

AWS A5.5 E11018-G H4 | -40 ℃ | Polarity:DCEP | |

| SAW |

PF-H80AK /

US-80LT

|

AWS A5.23 F12A10-EG-G JIS Z3183 S804-H4 |

-40 ℃ | Polarity:AC |

|

PF-H80AS/

US-80LT

|

AWS A5.23 F11A10-EG-G | -40 ℃ | Polarity:DCEP | |

| GMAW |

DW-A80L

|

AWS A5.29 E111T1-GM-H4 EN ISO 18276 -A- T69 4 Z P M 2 H5 |

-40 ℃ | Shield gas:Ar-CO2 All position |

|

MX-A80L

|

AWS A5.29 E111T1-GM-H4 EN ISO 1876 -A- T69 6 Mn2.5ni M M3 H5 |

-60 ℃ | Shield gas:Ar-CO2 Flat / Horizontal |

|

|

MG-S88A

|

AWS A5.28 ER120S-G JIS Z3312 G78A 6 U M N7M4T |

-40 ℃ | Shielding Gas:Ar-CO2 | |

| GTAW |

TG-S80AM

|

AWS A5.28 ER110S-G JIS Z3316 W78 A 6 N6C1M4 |

-60 ℃ | Polarity:DCEP |

- *stands for FAMILIARC™,stands for TRUSTARC™,and stands for PREMIARC™.

FCAW: Flux-Cored Wire TRUSTARC™ DW-A80L

- Rutile based flux-cored wire for Ar-CO2 shielding gas, good usability in all positional welding.

- Good notch toughness down to -40°C in as-welded condition.

- Excellent crack resistance due to low diffusible hydrogen.

- Applicable for 780 MPa class grade steel of offshore structure

AWS A5.29 E111T1-GM-H4

EN ISO 18276-A-T69 4 Z P M 2 H5

Shipping approvals: ABS, LR, DNV, GL and NK

Typical Test Result of Depositied Metal

| Chemical Composition | Diffusible Hydrogen Content (ml/100g) |

||||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | Mo | |

| 0.07 | 0.31 | 1.86 | 0.007 | 0.006 | 2.49 | 0.16 | 2.4 |

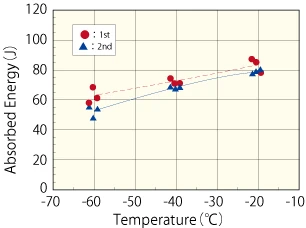

Typical Mechanical Test Results of Weld Joint

Welding parameter

- Position

vertical up

- Welding parameter

200A-24V

- Base metal

K-TEN780, 50 mmt

- Shielding gas

80% Ar-20%CO2

Tensile Test Result

| 0.2% Y.S. (MPa) |

T.S. (MPa) |

Elongation (%) |

|

|---|---|---|---|

| 1st | 738 | 817 | 24 |

| 2st | 736 | 811 | 23 |

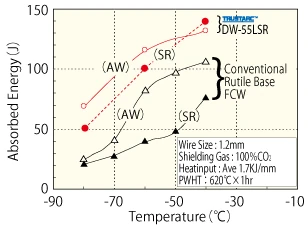

TRUSTARC™ DW-55LSR/DW-A55LSR

FCAW with Unsurpassed Notch Toughness in AW/SR condition

Features

- Revolutionary rutile-base flux-cored wires having unsurpassed notch toughness in SR condition as well as in the as-welded condition at low temperatures down to -60°C and excellent usability in all position welding.

Typical Test Result of Depositied Metal

| Product | Chemical Composition | Diffusible Hydrogen Content (ml/100g) |

|||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | ||

DW-55LSR |

0.06 | 0.26 | 1.15 | 0.008 | 0.007 | 1.39 | 3.9 |

DW-A55LSR |

0.05 | 0.33 | 1.32 | 0.009 | 0.008 | 0.90 | 3.9 |

- *stands for FAMILIARC™,stands for TRUSTARC™,and stands for PREMIARC™.

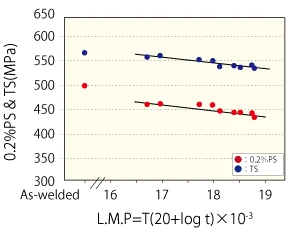

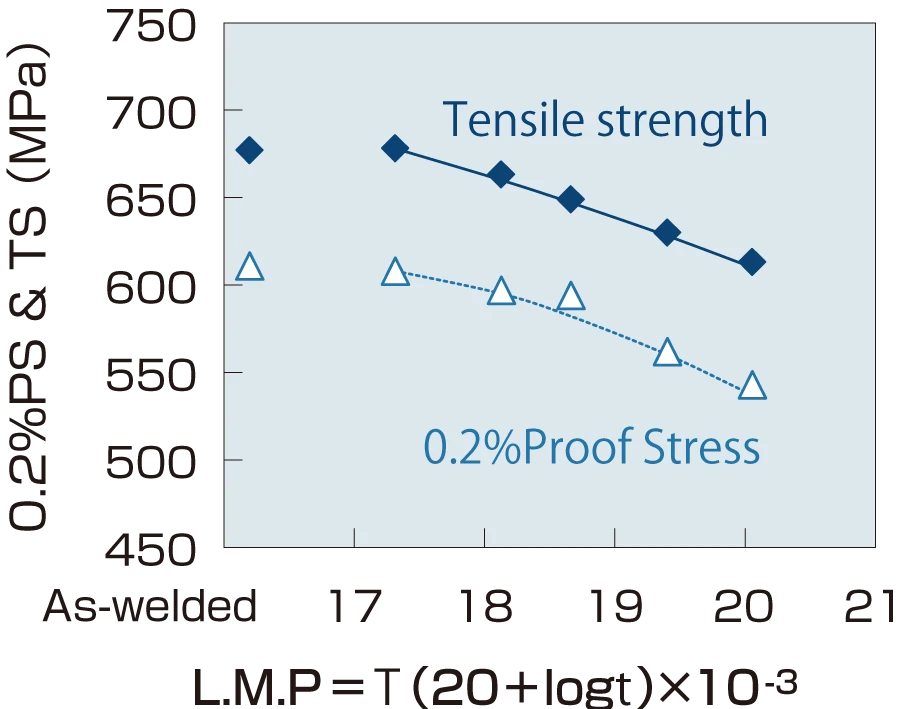

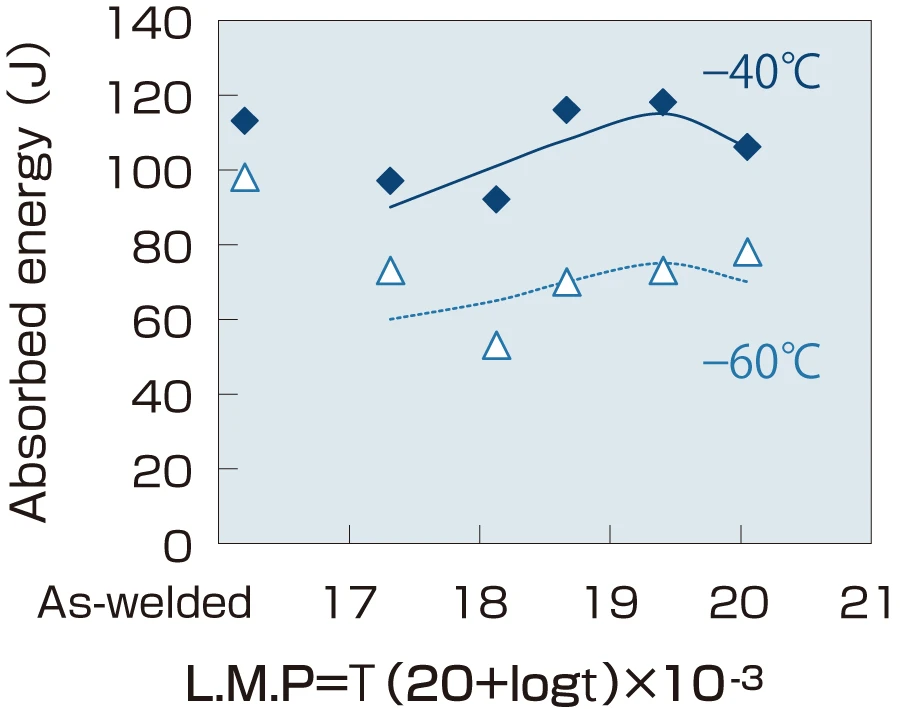

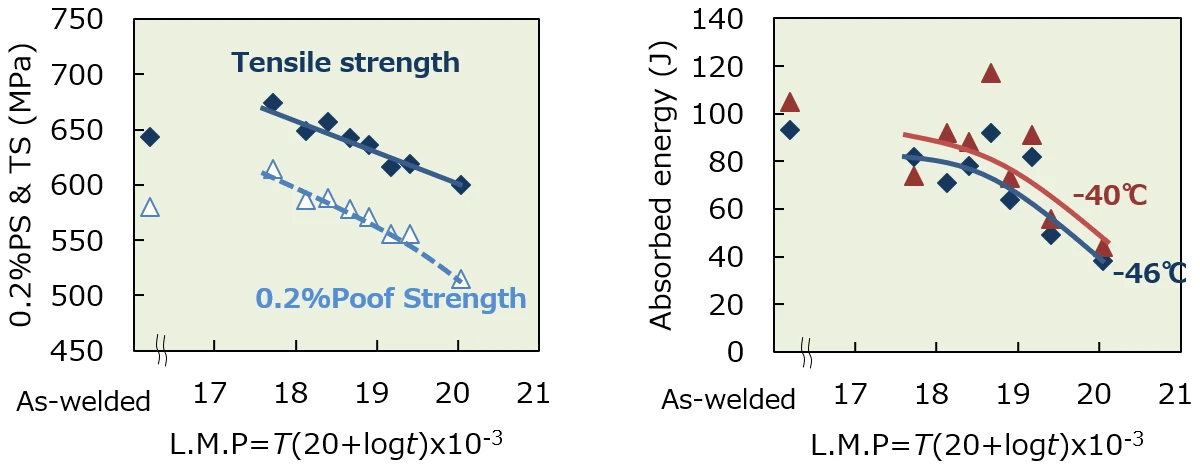

Typical Mechanical Test Results

TRUSTARC™ DW-A62LSR for 610MPa Class Steel

FCAW with Unsurpassed Notch Toughness in AW/SR condition

Application and Features

- Application: Presssure vessels, spherical tank, and etc.

- Less deterioration of notch toughness with SR

- Excellent notch toughness at -60℃ with as-welded condition/-40℃ with SR

- Excellent usability in all position welding

AWS A5.29 E91T1-GM

Typical Chemical Composition and Mechanical Properties of Deposited Metal

| Chemical Composition of Deposited Metal (%) | Diffusible Hydrogen (ml/100g) |

||||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | Others | |

| 0.05 | 0.14 | 1.29 | 0.007 | 0.008 | 2.59 | Mo, Ti, B | 3.9 |

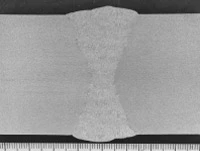

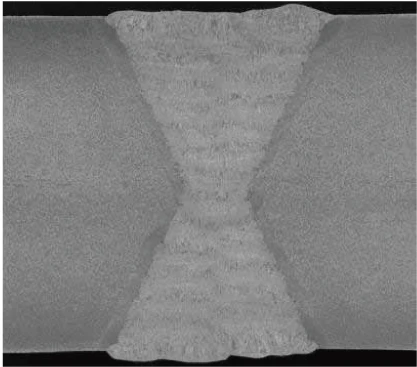

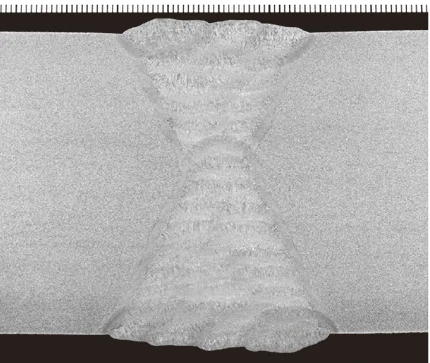

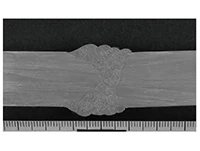

Macrostructures (Example)

Welding parameter

- Welding Position

Vertical Upward

- Current-Voltage

220A-24V

- Base Metal

K-TEN610,60mm

- Shielding Gas

80%Ar-20%CO2

TRUSTARC™ DW-A61LSR for 610MPa Class Steel

FCAW with Unsurpassed Notch Toughness in AW/SR condition & Satisfying NACE MR0175 (Ni < 1.0%)

Application and Features

- Application: Presssure vessels, spherical tank, and etc.

- Low Ni content (<1.0%) satisfying NACE MR0175 & ISO 15156

- Excellent notch toughness at -50℃ with as-welded condition/-40℃ with SR

- Excellent usability in all position welding

AWS A5.29 E91T1-GM

Typical Chemical Composition and Mechanical Properties of Deposited Metal

| Chemical Composition of Deposited Metal (%) | Diffusible Hydrogen (ml/100g) |

||||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | Others | |

| 0.05 | 0.16 | 1.39 | 0.007 | 0.004 | 0.92 | Cu, Mo, Ti, B | 3.3 |

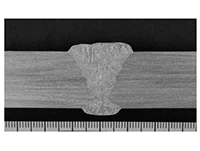

Macrostructures (Example)

Welding parameter

- Welding Position

Vertical Upward

- Welding Conditions

200A-23V

- Base Metal

TEN610,60mm

- Shielding Gas

80%Ar-20%CO2

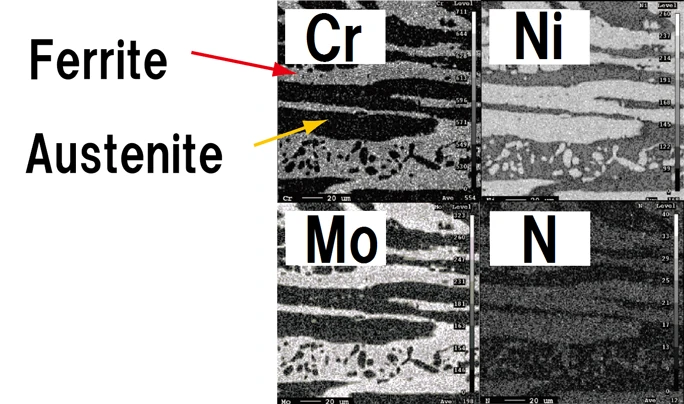

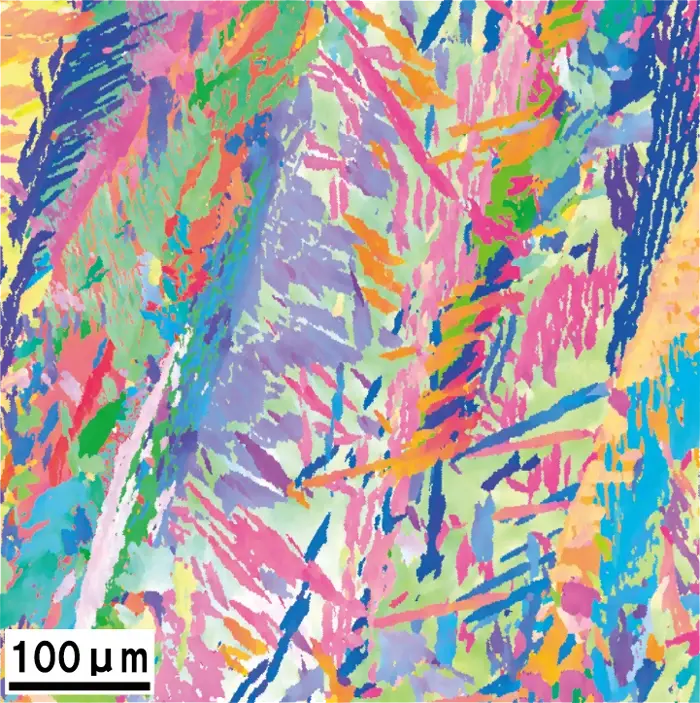

Welding Consumables for Duplex Stainless

What is Duplex Stainless ?

- With microstructure consisting virtually 50% austenite phase and 50% ferritic phase, duplex stainless possesses

- excellent ductility, notch toughness, and resistance to stress corrosion cracking

- -is classified into standard, lean, and super duplex.

Class of Duplex Stainless Steel and Applicable Welding Material

| Class | Feature | Welding Material / Grade |

Welding Process | Trade Designation | ||

|---|---|---|---|---|---|---|

| FCAW | DW-2307 |

DW-2209/

DW-329AP

|

DW-2594 |

|||

| SMAW | - | NC-2209 |

NC-2594 |

|||

| GTAW | - |

TG-S2209

|

TG-S2594

|

|||

| Lean Duplex | Less Ni, Mo content than standard duplex. substitute for SUS304 (L) and SUS316 (L) | UNS-S32101 | ◎ | ○ | ○ | |

| UNS-S32304 | ◎ | ○ | ○ | |||

| UNS S82122 | ◎ | ○ | ○ | |||

| Standard Duplex | Most common duplex, applicable for wide range of industries | UNS S31803 | × | ◎ | ○ | |

| UNS S32205 | × | ◎ | ○ | |||

| SUS329J3L | × | ◎ | ○ | |||

| SUS329J4L | × | × | ○ | |||

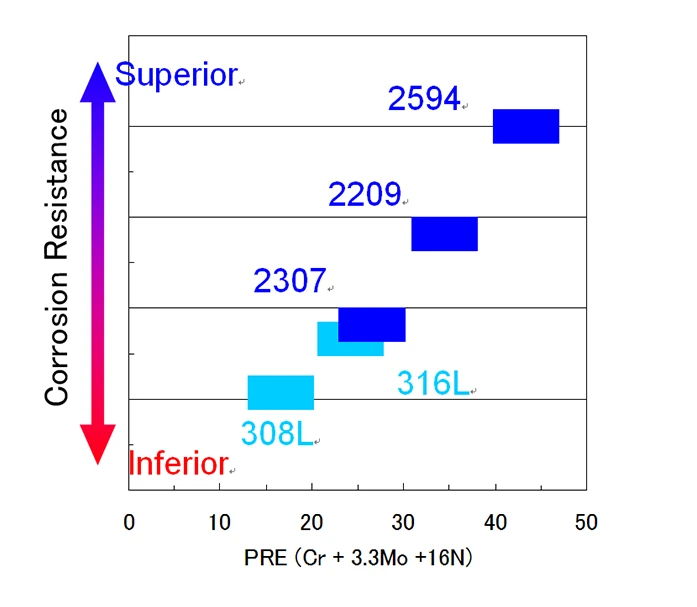

| Super Duplex | With PRE=Cr+3.3Mo+16N≧40, most excellent corrosion resistance | UNS S32750 | × | × | ◎ | |

| UNS S32760 | × | × | ◎ | |||

- ◎: Applicable, with similar composition ○: Applicable ×: Not-applicable

Our Product Line-up

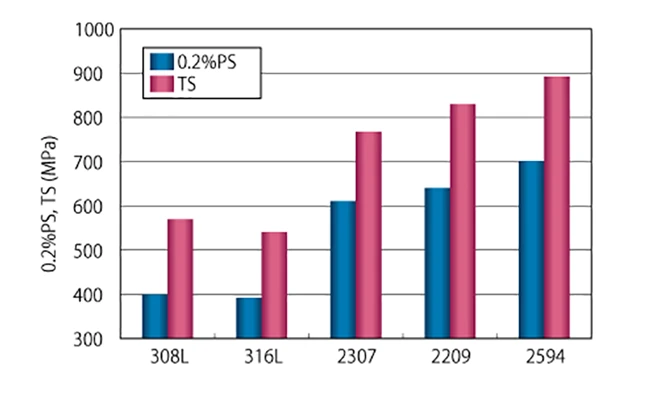

| Class | Trade Designation | Process | AWS | Typical Chemical Composition (mass.%) | PRE* | Typical Mechanical Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Ni | Cr | Mo | N | 0.2% PS |

TS | EI | vE | |||||

| (MPa) | (MPa) | (%) | (0°ree;C, J) | ||||||||||||

| Lean Duplex | DW-2307 |

FCAW | A5.22/A5.22M E2307T1-1/4 | 0.026 | 0.45 | 1.26 | 7.9 | 24.6 | 0.03 | 0.15 | 27.1 | 571 | 750 | 29 | 58 |

| Standard Duplex | TG-S2209 |

GTAW | A5.9/A5.9M ER2209 | 0.008 | 0.39 | 1.67 | 8.7 | 22.7 | 3.10 | 0.16 | 35.5 | 598 | 773 | 39 | 270 |

NC-2209 |

SMAW | A5.4/A5.4M E2209-16 | 0.028 | 0.54 | 1.14 | 8.8 | 23.1 | 3.34 | 0.15 | 36.5 | 667 | 845 | 30 | 97 | |

DW-2209 |

FCAW | A5.22/A5.22M E2209T1-1/4 | 0.028 | 0.61 | 0.74 | 9.1 | 22.7 | 3.30 | 0.13 | 35.6 | 639 | 820 | 28 | 73 | |

DW-329AP |

FCAW | A5.22/A5.22M E2209T1-1/4 | 0.024 | 0.63 | 0.80 | 9.2 | 23.0 | 3.49 | 0.13 | 36.6 | 643 | 832 | 28 | 55 | |

US-2209/ PF-S1D |

SAW | A5.9/A5.9M ER2209(Wire) | 0.021 | 0.31 | 1.56 | 8.9 | 23.0 | 3.28 | 0.15 | 35.9 | 618 | 798 | 29 | 69 | |

| Super Duplex | TG-S2594 |

GTAW | A5.9/A5.9M ER2594 | 0.019 | 0.44 | 0.57 | 9.3 | 25.0 | 3.82 | 0.28 | 42.0 | 721 | 870 | 31 | 286 |

NC-2594 |

SMAW | A5.4/A5.4M E2594-16 | 0.035 | 0.55 | 0.66 | 9.8 | 26.6 | 3.86 | 0.25 | 43.3 | 750 | 935 | 28 | 55 | |

DW-2594 |

FCAW | A5.22/A5.22M E2594T1-1/4 | 0.026 | 0.50 | 1.18 | 9.6 | 25.7 | 3.79 | 0.24 | 42.0 | 712 | 905 | 27 | 55 | |

- * PRE = Cr + 3.3Mo +16N, mass%

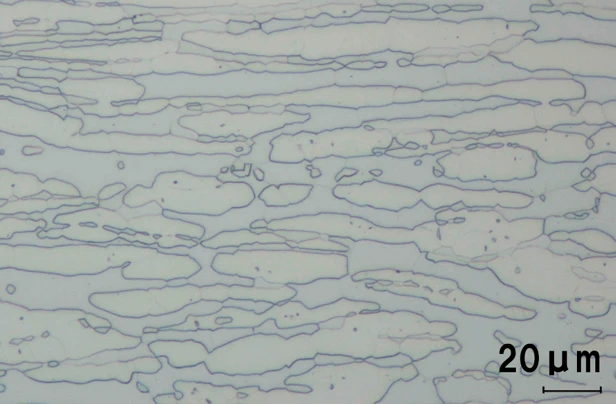

Excellent Corrosion Resistance / Strength

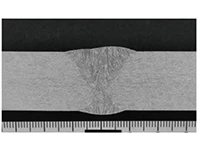

Excellent Porosity-Resistance, Sound Weld-joint

High porosity-resistant and sound weld joint

Base metal: S31803 (20t)

Welding position: Horizontal (2G)

Base metal: S32760 (20t)

Welding position: Vertical-up (3G)

Base metal: S32304 (20t)

Welding position: Flat (1G)

Welding Materials for Offshore Structures

- *Use polarity as indicated. Products with "SR" can be used in PWHT condition and As-welded condition, otherwise in As-welded only.

FCAW: Flux-Cored Wire

CO2 100%

Ar + 20% CO2

| TS (MPa) min. | 490 | 520 | 550 | 610 | 670 | 700 | |

|---|---|---|---|---|---|---|---|

| PS (MPa) min. | 350 | 400 | 420 | 500 | 550 | 690 | |

| vE (J) min. | 35 | 40 | 42 | 50 | 55 | 69 | |

| Service temperature ( ℃) |

-20 | DW-A50 |

DW-A81Ni1 DW-A62LSR(SR) |

DW-A61LSR(SR) DW-A65L DW-A65Ni1 |

DW-A70L |

DW-A80L |

|

| -40 | DW-A55ESR(SR) |

||||||

| -50 | DW-A55L MX-A55Ni1 MX-A55T |

DW-A55L MX-A55Ni1 MX-A55T |

DW-A81Ni1 |

DW-A61LSR |

MX-A80L |

||

| -60 | DW-A55L DW-A62LSR MX-A55Ni1 MX-A55T |

MX-A62L |

|||||

- *MG: Solid wire

- *MX: Metal-cored wire

SMAW: Stick Electrode (DC)

| TS (MPa) min. | 490 | 520 | 550 | 610 | 670 | 770 | |

|---|---|---|---|---|---|---|---|

| YS (MPa) min. | 350 | 400 | 420 | 500 | 550 | 690 | |

| IV (J) min. | 35 | 40 | 42 | 50 | 55 | 69 | |

| Service temperature ( ℃) |

-20 | LB-52(SR) LB-52-18 |

LB-57 |

LB-62UL LB-62(SR) LB-62U(SR) |

LB-106 |

||

| -40 | LB-52U LB-7018-1 |

LB-55NS(SR) |

LB-67L(SR) LB-67LJ |

LB-70L |

|||

| -60 |

LB-52NSU(SR) |

– | |||||

SMAW: Stick Electrode (AC)

| TS (MPa) min. | 490 | 520 | 550 | 610 | 670 | 770 | |

|---|---|---|---|---|---|---|---|

| YS (MPa) min. | 350 | 400 | 420 | 500 | 550 | 690 | |

| IV (J) min. | 35 | 40 | 42 | 50 | 55 | 69 | |

| Service temperature ( ℃) |

-20 | LB-52(SR) LB-52-18 |

LB-57(SR) |

LB-62UL LB-62(SR) LB-62U(SR) |

LB-106 |

LB-80UL LB-116 |

|

| -40 | LB-52U(SR) |

LB-52NSU(SR) |

LB-62L(SR) |

LB-Y75 |

LB-88LT |

||

| -60 | LB-52NSU(SR) |

||||||

- *TRUSTARC™ LB-52U, LB52NSU and TRUSTARC™ LB-62U: for Uranami welding

SAW: Submerged Arc Welding (DCEP)

| TS (MPa) min. | 490 | 520 | 610 | 670 | 770 | |

|---|---|---|---|---|---|---|

| YS (MPa) min. | 350 | 400 | 500 | 550 | 690 | |

| IV (J) min. | 35 | 40 | 50 | 55 | 69 | |

| Service temperature ( ℃) |

-20 | PF-H55AS / US-36J(SR) |

PF-H55AS / US-36J PF-H58AS / US-36J |

PF-H80AK / US-56B |

PF-H80AS / US-255 |

PF-H80AS / US-80LT |

| -40 | ||||||

| -60 | PF-H62AS / US-2N |

– | ||||

SAW: Submerged Arc Welding (AC)

| TS (MPa) min. | 490 | 520 | 550 | 610 | 670 | 770 | |

|---|---|---|---|---|---|---|---|

| YS (MPa) min. | 350 | 400 | 420 | 500 | 550 | 690 | |

| IV (J) min. | 35 | 40 | 42 | 50 | 55 | 69 | |

| Service temperature ( ℃) |

-20 | PF-H55LT / US-36(SR) |

MF-38 / US-49A(SR) |

MF-38 / US-40 |

PF-H80AK / US-255 |

PF-H80AK / US-80LT |

|

| -40 | PF-H55S / US-49A(SR) |

PF-H55S / US-40 PF-H80AK / US-56B |

|||||

| -60 | PF-H55LT / US-36 PF-H55LT / US-36J(SR) |

PF-H55LT / US-36J |

PF-H80AK / US-56B PF-H55S / US-2N(SR) |

||||

- MF-38: Fused type flux

- TRUSTARC™ PF-H: Bonded type flux

GTAW: TIG

| TS (MPa) min. | 490 | 520 | 550 | 610 | 670 | 770 | |

|---|---|---|---|---|---|---|---|

| YS (MPa) min. | 350 | 400 | 420 | 500 | 550 | 690 | |

| IV (J) min. | 35 | 40 | 42 | 50 | 55 | 69 | |

| Service temperature ( ℃) |

-20 | TG-S50(SR) TG-S51T(SR) |

TG-S62(SR) |

TG-S80AM(SR) |

|||

| -30 | TG-S60A(SR) |

||||||

| -40 | TG-S1MT TG-S1N |

||||||

| -60 | |||||||

Contact Us

You can reach us by clicking the inquiry button.