Home > About Us > Corporate Social Responsibility > Sustainability Report > Sustainability Report 2009 > Resource Recycling Measures

Menu

- Corporate Social Responsibility

-

- Third-Party Comment and Editorial Postscript

- Reader Evaluations

- Emission Data of Production Facilities

- Thorough risk management

- Promotion of Employee Initiatives

- Cooperation with the Local Community

- Disclosure of Environmental Information

- Contributing to the Environment through R&D

- Products, Technologies and Services to Benefit the Environment

- Environmental Accounting

- Reducing the Environmental Burden

- Proper Control of Chemical Substances

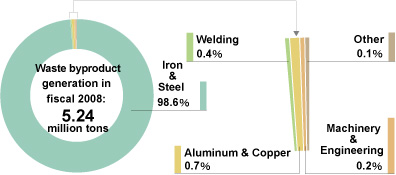

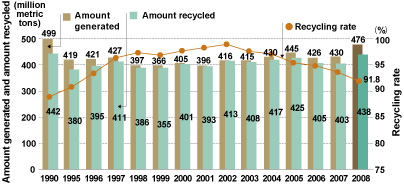

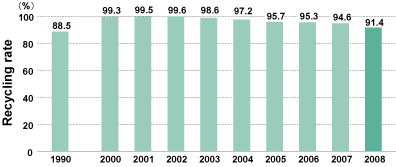

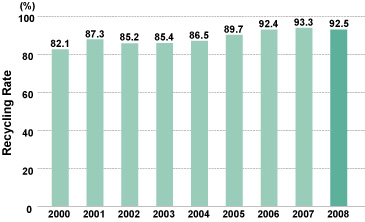

- Resource Recycling Measures

- Measures Against Global Warming

- Medium-Term Environmental Targets, Results and Evaluation

- Material Balance

- Countermeasures for Air Emission Problem at Steelworks

- Policy and Framework for Environmental Management

- Eco Highlights

- Disaster Prevention Activities

- Creating an Attractive Working Environment

- Relations with Shareholders and Investors

- Relations with Customers and Business Partners

- Contributing to Society

- Highlights on Society

- Strengthening Compliance

- Corporate Social Responsibility and Corporate Governance

- 2. Upgraded Brown Coal

- 1. ITmk3 Ironmaking Technology

- Overview of the Kobe Steel Group

- Message from the President

- Home

- About Us

- Corporate Social Responsibility

- Sustainability Report

- Sustainability Report 2009

- Resource Recycling Measures