Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2015 > Contributing to the Environment through R&D

Contributing to the Environment through R&D

Contributing to the Environment through R&D

Developing Material Technologies that Contribute to Lower CO2 Emissions

![]()

We aim to create and help bring about the widespread use of innovative materials that are strong, light and heat resistant—and designed to help curb CO2 emissions.

At Kobe Steel, we are working on research and development of materials that enable lower automobile and aircraft CO2 emissions, techniques for joining such materials and structural design technologies. We aim to help ease environmental loads by developing technologies that take full advantage of specific characteristics found in a diverse range of materials including high-strength steel sheets, titanium alloys and aluminum alloys, which are core products of the Kobe Steel Group.

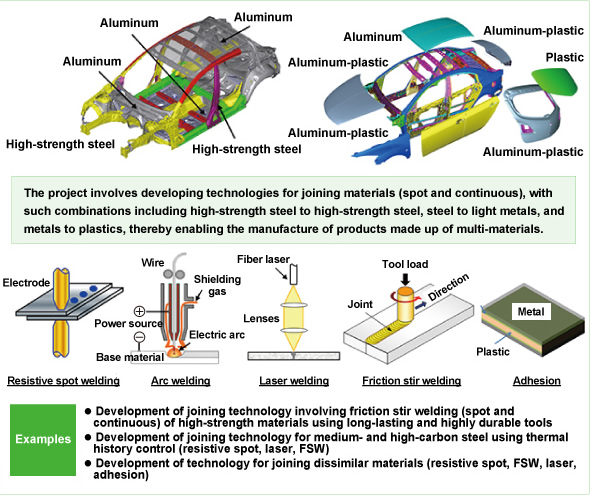

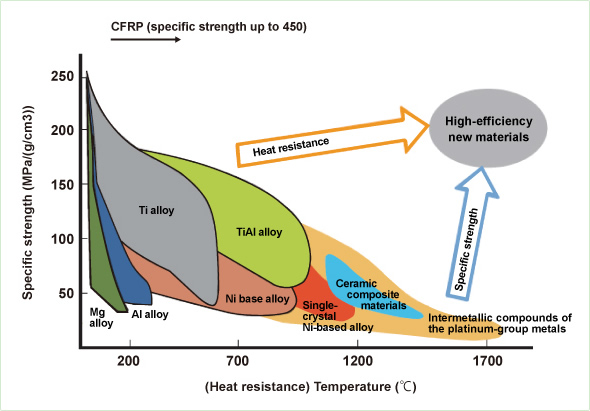

Beyond our own R&D initiatives in the field of material technologies, we also take part in national government projects. Examples include a project to develop new and innovative structural material technologies1 and also the Cross-ministerial Strategic Innovation Promotion Program for Innovative Structural Materials2.

As a materials manufacturer, Kobe Steel will continue its efforts to develop practical applications while strengthening its base of industrial technologies, through industry-academia partnerships and cooperative initiatives with companies that use such materials.

1. Implemented by the Innovative Structural Materials Association (ISMA), and commissioned by the New Energy and Industrial Technology Organization (NEDO)

2. Research project of the Strategic Innovation Program (SIP), commissioned by the Japan Science and Technology Agency (JST)

Aims of the project for the development of new and innovative structural material technologies

(Illustration courtesy of ISMA)

Aims of the Strategic Innovation Promotion Program for Innovative Structural Materials

(Illustration courtesy of JST)

Reducing Environmental Impact by Decreasing the Frequency of Bridge Repainting

![]()

Development of Eco-View Steel Plate for Bridges Enables Longer-lasting Painted Surfaces

Use of Eco-View steel plate on

the Taima Number 2 Bridge,

located on the Minami-Hanna

Road in Nara Prefecture

(steel superstructure public

works project)

Kobe Steel has developed Eco-View steel plate for bridges which extends intervals between paintings by 1.5 times in comparison with bridges using conventional steel. Results of 10-year weathering experiments confirmed that Eco-View steel plate has effective corrosion resistance1 in comparison with conventional steel. The use of Eco-View steel plate installed on bridges helps reduce environmental loads by improving the durability of steel bridges while also reducing the number of times a bridge needs to be repainted during its service life.

As of April 2015, Eco-View steel plate has been used in 15 bridges in Japan. Moreover, it has also been registered with the Ministry of Land, Infrastructure and Transport’s New Technology Information System (NETIS)2 and is expected to become more widely used going forward.

1. Eco-View steel plate curbs the spread of corrosion that occurs beginning in areas that are inadequately coated, such as places where paint has been scratched.

2. NETIS, and acronym for New Technology Information System, is a database maintained by Japan’s Ministry of Land, Infrastructure and Transport for tracking new technologies that are used in public works projects and other such undertakings. It is designed to provide general information on such technologies in order to promote their use.