Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2015 > Disaster Prevention Initiatives

Disaster Prevention Initiatives

Disaster Prevention Initiatives

The Kobe Steel Group makes groupwide efforts to comply with laws and regulations, implement measures to guard against equipment accidents, and prepare for natural disasters through such means as establishing disaster management systems and holding regular training exercises. These measures are actively pursued to prevent accidents from occurring and to minimize damage if a disaster does strike.

We will continue to raise each and every employee's awareness for disaster preparedness while continuing to carry out disaster prevention activities on a groupwide basis.

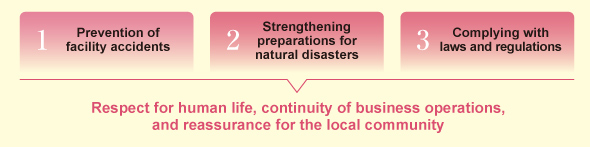

Fiscal 2014 Companywide Disaster Prevention Management Policy

![]()

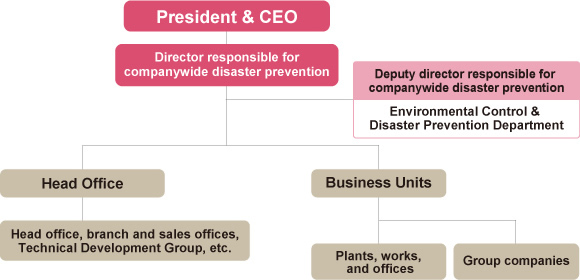

Companywide Disaster Prevention Management Structure

![]()

At the Kobe Steel Group, the head office, business units, business locations, and Group companies all implement disaster prevention management activities under the supervision of the president and the director responsible for companywide disaster prevention.

Companywide Disaster Prevention Management Structure

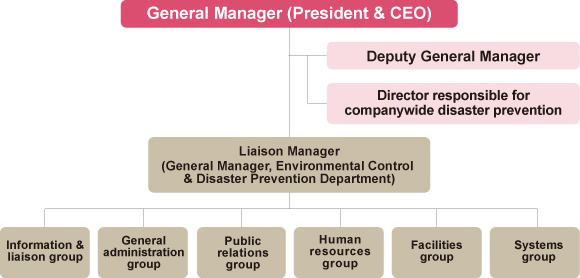

Kobe Steel Group Disaster Prevention Meeting

![]()

Disaster Prevention Meeting

We organize the Kobe Steel Group Disaster Prevention Meeting every year in an effort to share information and strengthen disaster prevention initiatives. A total of 130 employees from 54 Group companies took part in our fiscal 2014 meeting. In addition to natural disaster countermeasures such as companywide business continuity plans (BCP) for large-scale earthquakes, tsunami countermeasures, earthquake early warning systems and heavy rainfall countermeasures, we also reported on examples of accidents from other companies. The meeting once again made participants aware of the risks of natural disasters and the importance of effective countermeasures.

Response System in the Event of a Disaster

![]()

Drill for setting up the disaster

response headquarters

In the event of a large-scale earthquake or other natural disaster or accident, we will set up a disaster response headquarters at our Tokyo Head Office or Kobe Head Office to coordinate relief efforts and restoration activities.

When the Great East Japan Earthquake struck in March 2011, we established a headquarters at our Tokyo Head Office to verify people's safety and provide assistance for affected locations. We also provided support to get operations up and running again as quickly as possible, including arranging and shipping relief supplies.

On March 16, 2015, in preparation for the possibility of a large-scale earthquake occurring in Tokyo, we carried out drills for setting up a disaster response headquarters. The drills focused on initial post-earthquake response.

We intend to continue our educational and training activities in the future to ensure that we can respond as smoothly as possible in times of emergency.

Disaster Response Headquarters Organization

Disaster Prevention Measures at Works, Plants and Offices

![]()

Although the Kobe Steel Group makes every effort to prevent fires and other accidents before they occur, we were once again unable to completely eliminate all such accidents in fiscal 2014. We have investigated the causes of all accidents and are taking appropriate action.

In the future, in an effort to eliminate facility accidents throughout the Kobe Steel Group, we will carry out extensive initiatives to reduce risks, including sharing information on accidents occurring within and outside the company and activities carried out in coordination with the voluntary action plans of industrial associations.

Accidents and Incidents at Company Locations in Fiscal 2014

| Location | Number of Incidents | Location | Number of Incidents |

|---|---|---|---|

| Kobe Works | 1 | Moka Plant | 0 |

| Kakogawa Works | 2 | Chofu Works | 0 |

| Fujisawa Plant* | 0 | Daian Plant | 0 |

| Ibaraki Plant | 0 | Harima Plant | 0 |

| Saijo Plant | 0 | Kobe Corporate Research Laboratories | 0 |

| Fukuchiyama Plant | 0 | Takasago Works | 1 |

*Includes the Production Center, Technical Center, and group company facilities.

Facility Accidents in Fiscal 2014

| Date and Location | Incident |

|---|---|

| April 2014 Kobe Works |

High temperature matter came into contact with water that had collected in the byproduct pit at the steelmaking plant, resulting in an eruption of steam and causing the building roof to catch on fire. |

| May 2014 Kakogawa Works |

A transformer at the rolling mill broke down, causing damage to a transformer substation power switch and resulting in a power outage. |

| June 2014 Kakogawa Works |

During a trial run of the air separation plant, which had undergone some construction work, oxygen leaked into the nitrogen line and caused a reaction with atmospheric gas in the rolling mill's annealing furnace, resulting in burn damage to a portion of the bearing cover. |

| February 2015 Takasago Works |

Oil leaked from the forging plant's quenching tank and caught fire due to radiant heat from the heating furnace. |

Disaster Prevention Activities at Locations

![]()

Regular Emergency Drills

Rescue and relief drill

(Moka Plant)

We conduct regular emergency drills at each of the Kobe Steel Group's works, plants, offices and other locations.

Knowing that an earthquake could occur at any time, the Moka Plant carries out separate earthquake drills to prepare for the possibility of an earthquake occurring during on weekdays, weekends or holidays. During drills carried out in fiscal 2014 for weekends and holidays, the plant practiced a variety of operations, including evacuating to primary and secondary evacuation sites, collecting and transmitting information, giving aid to injured people, and setting up temporary on-site response headquarters.

Additionally, as a means to minimize any damage or injury due to earthquakes, an early earthquake warning system was deployed at all manufacturing bases, headquarters, branch offices and sales offices.

In the future we will continue to strengthen hard and soft measures that are designed to both protect employee life and minimize damage to the surrounding community.

Disaster Prevention Inspections

![]()

Disaster prevention inspection

(Shinko Metal Products Co.,

Ltd.)

Kobe Steel's management at its locations conducts on-site disaster prevention inspections of facilities in order to verify levels of compliance with disaster prevention laws and regulations and to minimize risks that could potentially lead to accidents.

In fiscal 2014 we once again conducted inspections at Kobe Steel locations and group companies. We found no serious legal violations, but had to correct deficiencies in equipment management.

Going forward, we will continue to reinforce disaster prevention management systems throughout the Kobe Steel Group.

We engage in disaster preparedness activities, with the aim of becoming a corporate group that is trusted by the community.

Koji Yamamoto

Director Responsible for

Companywide Disaster

Prevention (Officer)

Disaster prevention activities for the Kobe Steel Group are carried out according to three basic principles: prevention of facility accidents, strengthening preparations for natural disaster, and compliance with disaster-related laws and regulations.

In fiscal 2014, in reference to examples of accidents that occurred within and outside the company, we carried out extensive initiatives to reduce the risk of accidents and increased our disaster preparedness.

In preparation for the possibility of a disaster occurring, we also implemented a variety of disaster prevention and disaster reduction initiatives, including establishment of business continuity plans (BCP) for large-scale earthquakes and guidelines for responding to tsunamis.

Twenty years have passed since the Great Hanshin-Awaji Earthquake, and four years since the Great East Japan Earthquake. Remembering the lessons we learned from these disasters, we will continue to be diligent in implementing activities, one by one. Our aim is to be a corporate Group that is strong against disasters, and which is trusted and respected by the community and society at large.