FASTMET® Process

FASTMET® is a direct reduction process using rotary hearth furnace (RHF).

Various carbon sources such as coal, coke breeze or carbon bearing wastes can be used as reductant. Reduction process is completed in 6 - 12 minutes.

Application

Ironmaking from iron ore

FASTMET® plant to be used as a core or supplemental ironmaking plant in a steel mill

High quality product, with a metallization degree of 85 - 92%, in the form of DRI (Direct Reduced Iron) or HBI (Hot Briquetted Iron), will be charged to Blast Furnace, Basic Oxygen Furnace or Electric Arc Furnace as a core or supplemental source of iron. Carbon content in DRI can be adjusted as per customer's requirement.

DRI can also be melted to produce hot metal (FASTIRON™) via FASTMELT® process, which combines RHF with the Electric Ironmaking Furnace (EIF™) to produce hot metal directly from hot DRI. This method provides an economical source of high purity hot metal and remarkably increases productivity for the succeeding steelmaking process.

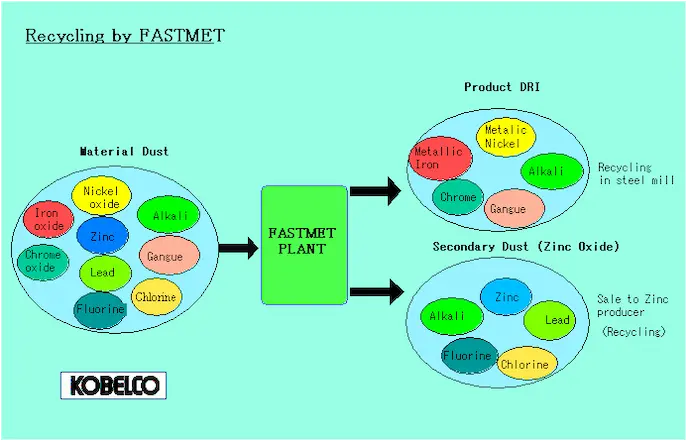

Recycling of steel mill wastes

FASTMET® plant to be used as a steel mill waste recycling plant

Steel mill wastes such as BF dust, BF Sludge, BOF dust, Sinter dust, EAF dust, mill scale, and etc., will be processed by FASTMET® plant. Benefits from this application will be ;

- Elimination of waste disposal cost and landfill liability

- Waste changed to a quality source of iron (DRI)

- To be recycled in iron or steel making process

Metallization degree:

Iron: 85 - 92%

Nickel: 95 - 100%

- To be recycled in iron or steel making process

- Recovery of Zinc contained in wastes (Zn deriving from scrap)

- To be sold to zinc producer

Zinc removal: 95% or higher

- To be sold to zinc producer

- Reclamation of carbon

- Carbon contained in dusts will be used as reductant

- Carbon content in DRI can be adjusted as per customer's requirement

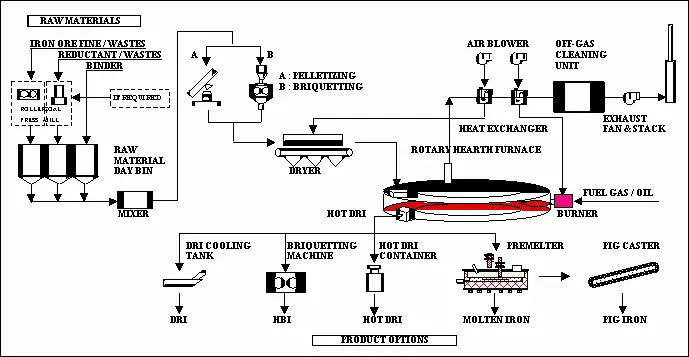

FASTMET® Process Flow

Environment

Kobe Steel, Ltd. also has abundant experiences on environmental matters, such as incinerator and sewerage plants. Experiences on incinerator plant have been adopted to FASTMET® process facilities, especially to off-gas system. All the environmental restrictions such as particulate, NOx, SOx, dioxin etc. will be cleared as was done in existing FASTMET® plants.

Reference List

| Client | Capacity (material processed) |

Start-up |

|---|---|---|

| Nippon Steel & Sumitomo Metal (Hirohata Works) |

190,000 tpy | April, 2000 |

| Kobe Steel, Ltd. (Kakogawa Works) |

16,000 tpy | April, 2001 |

| Nippon Steel & Sumitomo Metal (Hirohata Works No.2) |

190,000 tpy | February, 2005 |

| Nippon Steel & Sumitomo Metal (Hirohata Works No.3) |

190,000 tpy | December, 2008 |

| JFE (Fukuyama Works) |

190,000 tpy | April, 2009 |

| Kobe Steel, Ltd. J/V with NSSM (Nittetsu Shinko Metal Refine) |

190,000 tpy | October, 2011 |

Contact Us

You can reach us by clicking the inquiry button.