Pellet Plant (KOBELCO Pelletizing System)

KOBELCO Pelletizing System

Features of KOBELCO Pelletizing System

In 1966, Kobe Steel obtained a license for the Great Kiln process from Allis-Chalmers and developed the current KOBELCO Pelletizing System as its own exclusive technology.

The Great Kiln process utilizes a rotary kiln in the induration area, which decreases uneven pellet firing compared to other systems and facilitates the production of high-quality pellets.

The KOBELCO Pelletizing System exhibits its strength, incorporating Kobe Steel's extensive experience and know-how:

- Utilizing Kobe Steel's know-how as a pellet plant supplier and as a pellet manufacturer operating a pellet plant at its Kakogawa Works.

- Capable of designing optimal pellet plants from the user's perspective, leveraging the experience of using pellets as a raw material in blast furnaces at Kakogawa Works as well as in direct reduction (DR) plants overseas.

- Our delivery record includes the world's largest grate-kiln pellet plant using 100% hematite ore, with an annual production capacity of 6 million tons.

We implement optimal process design based on sample testing to provide reliable plants capable of producing high-quality pellets. Customers from around the world have been praising our expertise in building highly-efficient pellet plants, as well as our exceptional technical assistance and after-sales support.

Together with our subsidiary Midrex Technologies, Inc., a leading company in the direct reduction ironmaking process, we can provide pellet and DR plants in package form, as well as seamless solutions tailored to customer needs, encompassing pellets as raw materials to direct reduced iron (DRI).

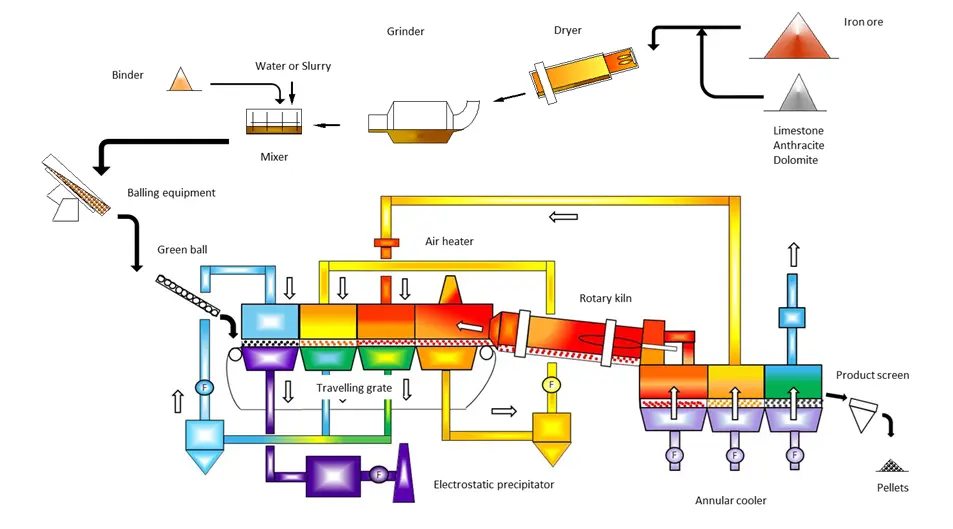

Process Flow

- Balling equipment

Forms the raw material into spherical green pellets

- Travelling grate

Dries, dehydrates, and preheates green pellets to prepare them for rolling in the kiln

- Rotary kiln

Fires pellets uniformly at high temperatures and at a low revolution

- Annular cooler

Cools the pellets to temperature suitable for transportation through horizontal rotation

- Product screen

Separates product pellets from raw materials for recycling

Delivery Record

| Country | Delivery location | Production capacity (million tons/year) |

Year of construction | Operation status |

|---|---|---|---|---|

| Japan | Kobe Steel's Kobe Works | 1.0 | 1966 | Shutdown |

| Japan | Nippon Steel Corporation | 0.4 | 1967 | Shutdown |

| Japan | Tetsugen Corporation | 0.2 | 1970 | Shutdown |

| Japan | Kobe Steel's Kakogawa Works No. 1 unit | 2.0 | 1970 | In operation (About 4 million tons/year) |

| Japan | Nippon Steel's Hirohata Works | 2.5 | 1973 | Shutdown |

| Japan | Kobe Steel's Kakogawa Works No. 2 unit | 2.0 | 1973 | Shutdown |

| Chile | Compañía de Acero del Pacífico S.A. de Inversiones | 3.5 | 1978 | In operation |

| Bahrain | Gulf Industrial Investment Co. (Current Bahrain Steel) |

4.0 | 1985 | In operation |

| Venezuela | C.V.G. Ferrominera Orinoco, C.A. | 3.3 | 1994 | In operation |

| Iran | Chador Malu Mining & Industrial Co. (Ardakan steelworks) | 3.4 | 2008 | In operation |

| Bahrain | Gulf Industrial Investment Co. (Current Bahrain Steel) |

6.0 | 2010 | In operation |

| Oman | Vale International S.A (Current Vale Oman Pelletizing Company L.L.C.) |

9.0 (4.5 x 2) |

2011 | In operation |

| Middle East | Not disclosed | 5.0 | 2019 | In operation |

(4.5 million tons/year x 2 pellet plants)

Contact Us

You can reach us by clicking the inquiry button.