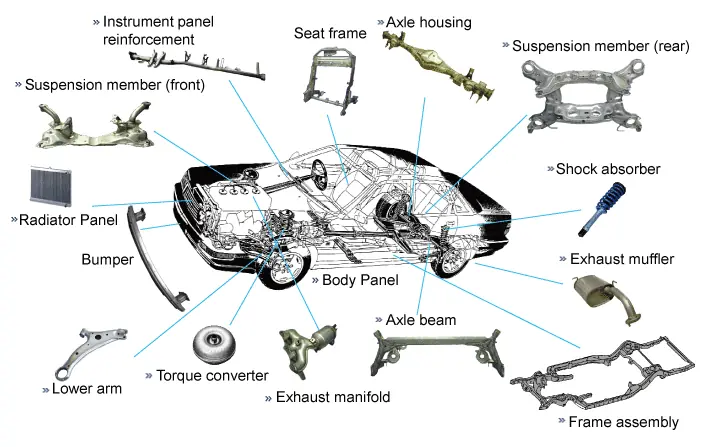

Automobile

Kobelco keeps on providing welding process and welding materials to solve all the problems car manufactures are facing.

- Welding Consumables for Automobiles

- SE wire, Non-Cu Coated Solid Wire

- Welding Solution - Galvanaized Steel Sheet

- Welding Wire for Ultra-High Tensile Steel

- Welding Process to Improve Rust Corrosion Resistance

- Welding Wire to Achieve Slag-Less welding

- Welding Wire Specially for Wire Feeding Control Process

Welding Consumables for Automobiles

-

Suspension member (front)

Suspension member

Suspension member - Plate thickness:

1.6 to 3.2mm

- Features:

galvanized steel plate

- Welding length:

long and short mixed

- Welding position:

Horizontal, Downhill

- Point:

Prevention of zinc-induced pits

Recommended welding procedure

- Power source:

Pulse or constant potential

- Shielding gas:

Ar 80% + CO2 20%, CO2 100%

- Welding position:

avoid vertical down welding as far as possible

- Welding current, speed:

150 to 250A – 60 to 120cm/min

- Welding wire:

FAMILIARC™ MIX-1TS, FAMILIARC™ MIX-1Z (Pulse)

FAMILIARC™ SE-50T, FAMILIARC™ MG-1Z (CO2) 1.2mmΦ

-

Instrument panel reinforcement

Instrument panel reinforcement

starting - Plate thickness:

0.8 to 1.4mm

- Features:

thin wall

- Welding length:

short

- Welding position:

Horizontal, Vertical-down

- Point:

Prevention measures to burn-through, consistent arc

Recommended welding procedure

- Power source:

Constant potential

- Shielding gas:

Ar 80-90% + CO2 20-10%, CO2

- Welding current, speed:

100 to 180A – 50 to 90cm/min

- Welding wire:

FAMILIARC™ SE-A50 1.0mmΦ

-

Axle housing

Axle housing

Axle housing - Plate thickness:

2.0 to 10.0mm

- Features:

Thick plate butt joint

- Welding length:

Fairly long

- Welding Position:

Flat

- Point:

Constant deep penetration

Recommended welding procedure

- Power source:

Constant potential (thick plate) or pulse

- Shielding gas:

CO2 100%, Ar 80%+CO2 20%

- Welding current, speed:

200 to 400A – 60 to 100cm/min

- Welding wire:

FAMILIARC™ MG-50 (CO2) , FAMILIARC™ SE-A50 (Pulse) 1.2, 1.6mmΦ

-

Shock absorber

Torque conveter, Shock absorber

Torque conveter - Plate thickness:

2.6 to 4.0mm

- Features:

circumferential welding

- Welding length:

long and short, mixed

- Welding position:

Horizontal

- Point:

Horizontal high-speed circumferential welding

Recommended welding procedure

- Power source:

Pulse or constant potential

- Shielding gas:

Ar 80% + CO2 20%, CO2

- Welding current, speed:

200 to 300A – 100 to 150cm/min

- Welding wire:

FAMILIARC™ MIX-50FS (Pulse)、FAMILIARC™ SE-A50FS (Pulse)、FAMILIARC™ SE-A50 (CP)

-

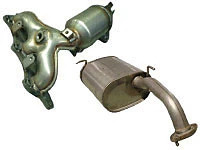

Exhaust muffler

Exhaust manifold, Muffler

Exhaust manifold - Plate thickness:

1.0 to 1.6mm

- Features:

Stainless steel

- Welding length:

long and short mixed

- Welding Position:

Flat

- Point:

Stainless steel, prevent sensitization, low spatter

Recommended welding procedure

- Power source:

Pulse

- Shielding gas:

Ar 98% + O2 2% Ar 80% + CO2 20%

- Welding current, speed:

120 to 200A – 30 to 80cm/min

- Welding wire:

PREMIARC™ MX-A430M, PREMIARC™ MM-430Nb (Ar100%)

-

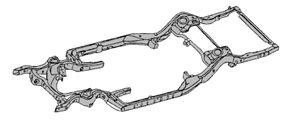

Frame assembly

Frame

Frame - Plate thickness:

2.3 to 4.0mm

- Features:

Many horizontal lap joints

- Welding length:

quite long

- Welding position:

Horizontal

- Point:

Large part, high speed, low spatter

Recommended welding procedure

- Power source:

Pulse or constant potential

- Shielding gas:

Ar 80% + CO2 20%

- Welding current, speed:

250 to 360A – 100 to 150cm/min

- Welding wire:

FAMILIARC™ SE-A50, FAMILIARC™ MIX-50FS 1.2mmΦ

-

Axle beam

Arm, axle beam

Arm, axle beam - Plate thickness:

2.6 to 3.2mm (arm), 2.6 to 4.0mm (axle)

- Features:

High strength, fatigue design

- Welding length:

Fairly long

- Welding position:

H, F, Downhill

- Point:

Strength part, extra-low spatter, high speed

Recommended welding procedure

- Power source:

Pulse or constant potential

- Shielding gas:

Ar 80% + CO2 20%

- Welding current, speed:

250 to 330A – 100 to 150cm/min

- Welding wire:

FAMILIARC™ SE-A50 (General), FAMILIARC™ MIX-1TS (VD), FAMILIARC™ MIX-50FS (H)

-

Body Panel

Body Panel

Body Panel - Plate thickness:

0.6 to 0.9mm

- Features:

Very thin plate

- Welding length:

very short

- Welding position:

Horizontal fillet, Vertical down, Horizontal

- Point:

Prevent burn-through and control root gap of very thin plate

Recommended welding procedure

- Power source:

Variable AC machine

- Shielding gas:

Ar 80% + CO2 20%

- Welding current, speed:

50 to 120A – 30 to 80cm/min

- Welding torch recommended:

Push-pull type

- Welding wire:

FAMILIARC™ MIX-1T 0.6 to 0.9mmΦ

-

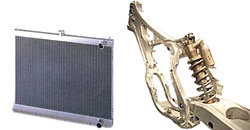

Radiator Panel

Radiator, Bike frame

Radiator, Bike frame - Plate thickness:

1.0 to 4.0mm

- Features:

Aluminum alloy

- Welding length:

long and short, mixed

- Welding position:

All positon

- Point:

Aluminum alloy

Recommended welding procedure

- Power source:

Pulse for aluminum alloys

- Shielding gas:

Ar 100%

- Welding current, speed:

100 to 250A – 50 to 100cm/min

- Welding wire:

PREMIARC™ A-5356WY, PREMIARC™ A-4043WY 1.2mmΦ

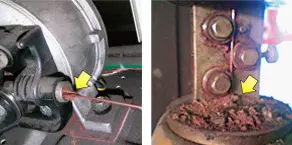

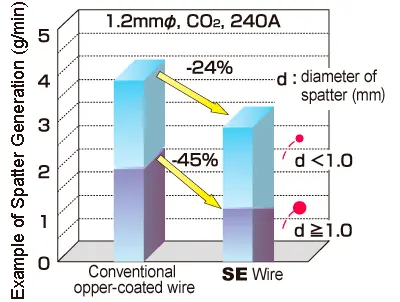

SE wire, Non-Cu Coated Solid Wire

With Kobelco's original wire surface treatment technology, non-copper-coated solid wire offers revolutionary level of wire feedability and unrivaled arc stability.

The copper coating process is eliminated from the manufacturing process to minimize the impact on the global environment.

Features

KOBELCO's own copper free, special wire surface treatment technology offers;

- Excellent wire feedability & stable arc

- Low spatter

- No trouble caused by copper coating scrap

Click the link below for "Technical Highlight Vol.12", advanced wires for car manufacturing.

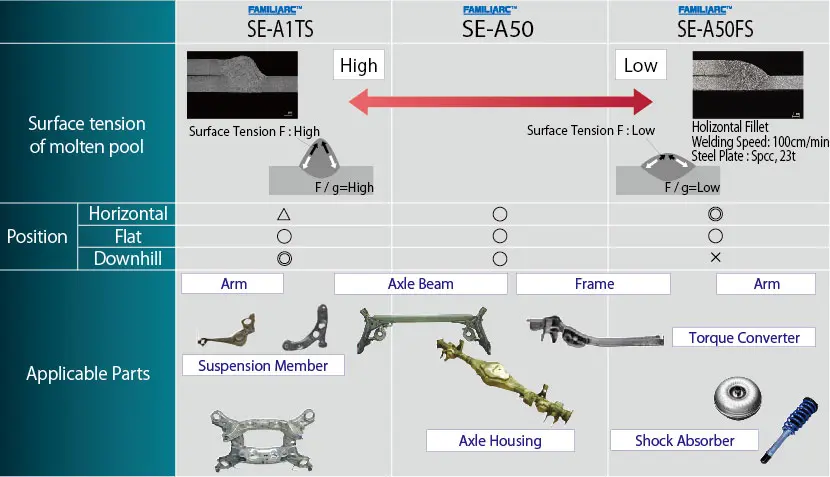

Series of SE Wire for Automobile

| Brand | Welding Process | Type of Steel (MPa) Thickness |

Chemical Composition (Example) | Mechanical properties (Example) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Y.S. (MPa) |

T.S. (MPa) |

El. (%) |

IV (J) |

|||

| CO2, MAG | Carbon steel pipe / plate (1 to 5mm) |

0.07 | 0.49 | 1.02 | 0.008 | 0.016 | 433 | 541 | 28 | 110 (0℃) |

|

| MAG, Pulsed MAG | Carbon steel pipe/plate (1 to 5mm) |

0.06 | 0.62 | 1.27 | 0.010 | 0.015 | 460 | 559 | 28 | 120 (-20℃) |

|

| MAG, Pulsed MAG | Carbon steel pipe / plate (3mm Above) |

0.08 | 0.35 | 1.06 | 0.009 | 0.011 | 460 | 540 | 28 | 150 (-20℃) |

|

| MAG, Pulsed MAG | Carbon steel pipe / plate (2 to 4mm) |

0.04 | 0.70 | 1.20 | 0.010 | 0.060* | 430 | 530 | 31 | 90 (0℃) |

|

| MAG, Pulsed MAG | Galvanized steel Anti-corrosive pipe (1 to 4mm) |

0.08 | 0.60 | 1.01 | 0.010 | 0.004 | 440 | 540 | 31 | 150 (-20℃) |

|

- *Although S content is higher than conventional wire, it is designed to maintain high-crack resistability.

Application to Automobile Parts

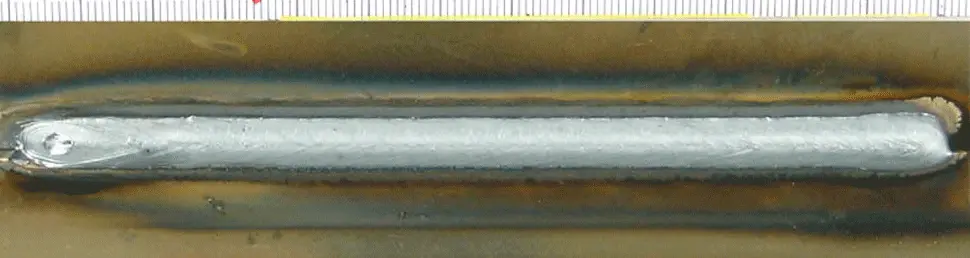

FAMILIARC™ SE-A50FS: Beautiful Flat and Expansive Beads

- Excellent bead contour in high speed welding, such as 90 to 140cm/min, without humping and undercut.

- Welding slag is condensed in one spot, not dispersed, and low in quantity.

- Its flat, wide bead shape is less likely affected by welding parameter, and more tolerble to deviated wire tracking.

Welding Solution - Galvanaized Steel Sheet

Welding Consumables for Galvanized Steel Sheet

| Process | Brand | Coating Weight | Anti-Porosity Resistance |

Welding Speed (cm/min) |

|

|---|---|---|---|---|---|

| CO2 | General | to 60g/m2 | Fair to Good | to 80 | |

| Special for galvanized steel | to 100g/m2 | Good | to 80 | ||

| PulseMAG | General | to 45g/m2 | Fair | to 100 (Horizontal) |

|

| Special for galvanized steel | to 60g/m2 | Good | |||

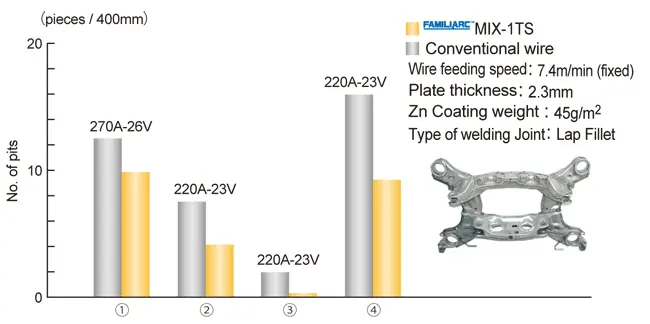

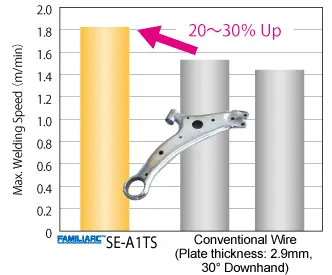

FAMILIARC™ MIX-1TS / FAMILIARC™ SE-A1TS

Excellent Anti-Porosity Resistance

| ① | ② | ③ | ④ | |

|---|---|---|---|---|

| Root gap | 0 | 0 | 1 | 0 |

| Welding powersouce | Constant potential | Pulse | ||

| Positon | Horizontal | 45° Downhill |

||

Excellent weldability with root gap

Butt joint (Thickness 3.2 mm, root gap 1.0 mm)

High Speed welding at downhill positon

Welding Wire for Ultra-High Tensile Steel

Feature 1

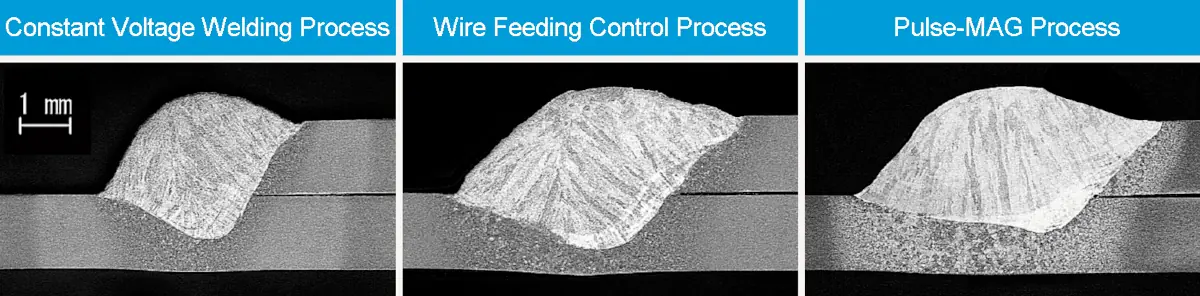

Applicable for various welding process, such as short circuit, pulse-MAG, and wire feeding control process

- *Shielding gas: Ar+20%CO2, sheet: 980TRIP/2.0mmt

Click here for "Technical Highlight Vol.28", MG-S120T & latest our welding techmology for car manufacture.

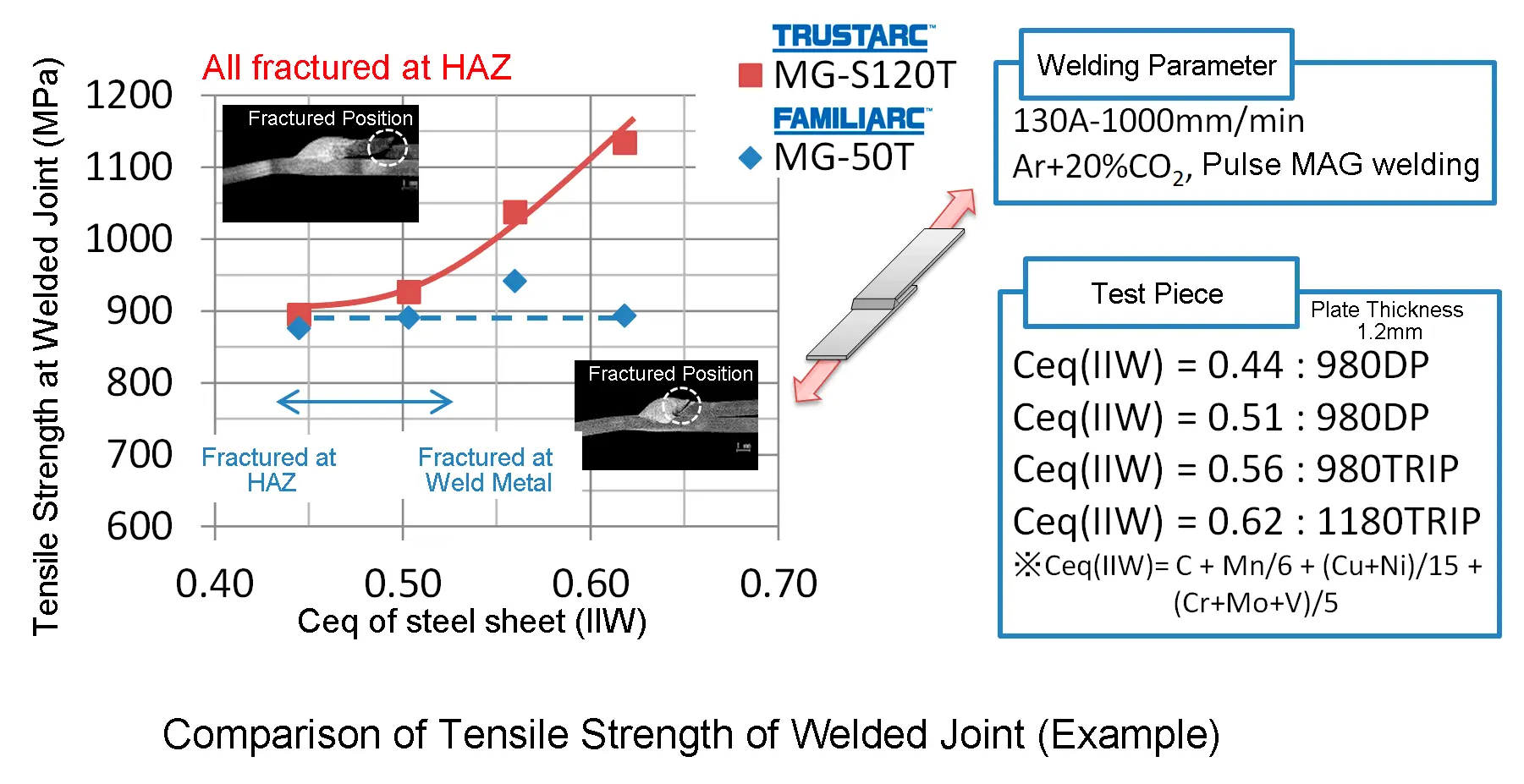

Feature 2

Achives sufficient strength welded joint with ultra-high tensile steel, while general welding wire does not achieve

Feature 3

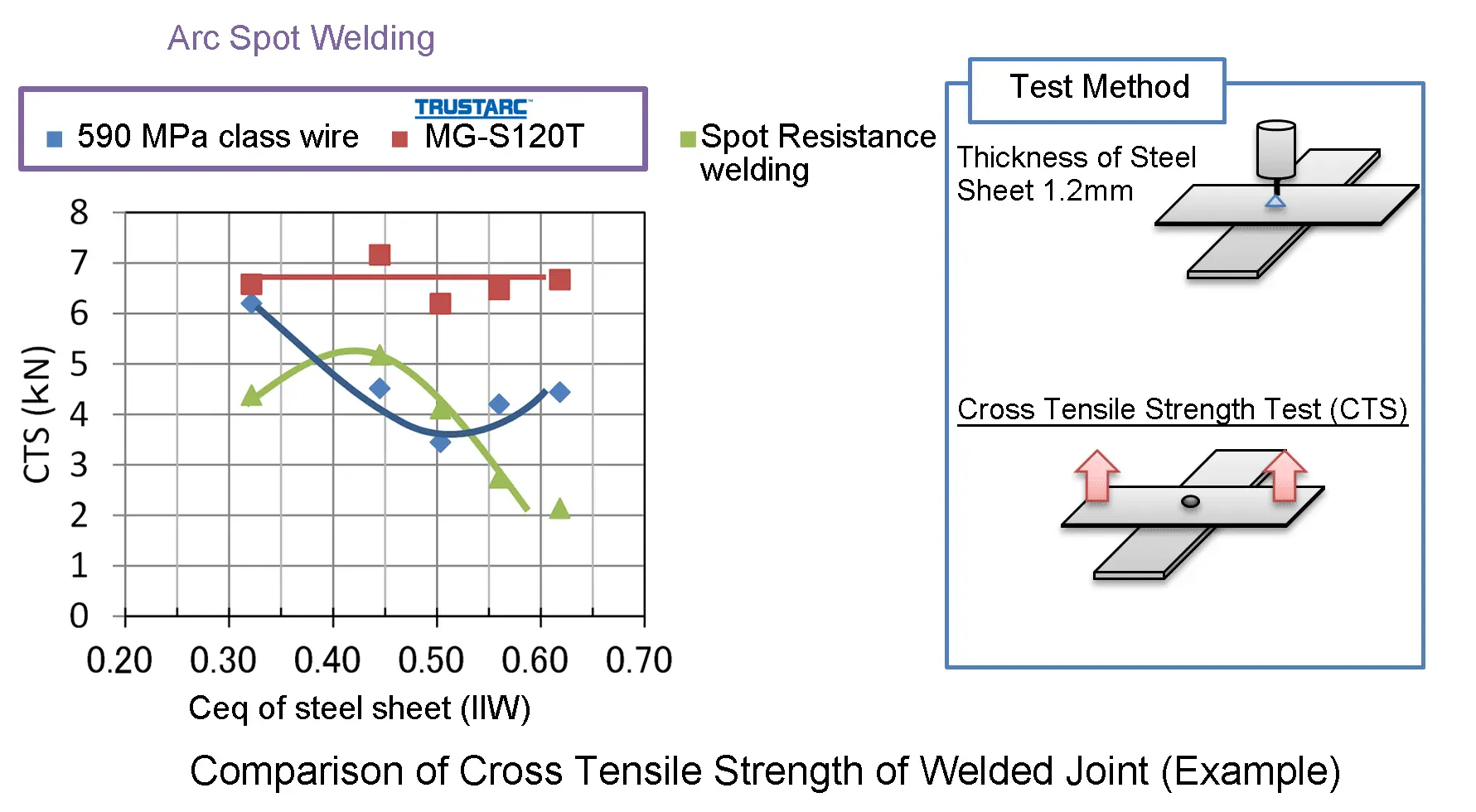

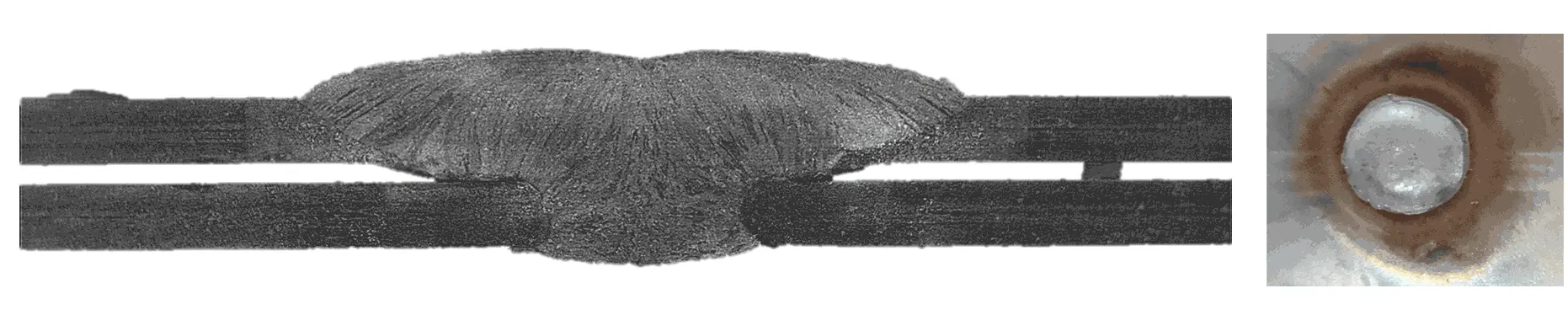

Achieves higher strength joint than spot resistance welding

- Welding current:

210A

- Arc time:

0.5sec

- Diameter of spot at lower plate:

4√t

- Current:

4KA

- Press:

440kgf

- Welding time:

15 cycle

- Nugget diameter:

4√t

TRUSTARC™ MG-S120T

Diffusible Hydrogen Content (According to JIS Z 3118)

Superior cold crack resistance due to low hydrogen content in weld metal

| Diffusible Hydrogen Content (ml/100g) | |||

|---|---|---|---|

| 1 | 2 | 3 | Average |

| 1.8 | 1.7 | 1.5 | 1.7 |

Applicable type of steel

780 to 1180MPa class carbon steel

- *Mechanical properties are affected by steel sheet. Users are kindly requested to confirm whether the weld metal have sufficient tensile strength with steel sheet which they intend to use.

Welding Process to Improve Rust Corrosion Resistance

Click the link below for welding wire and process to improve rust-corrosion resistance.

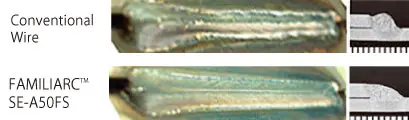

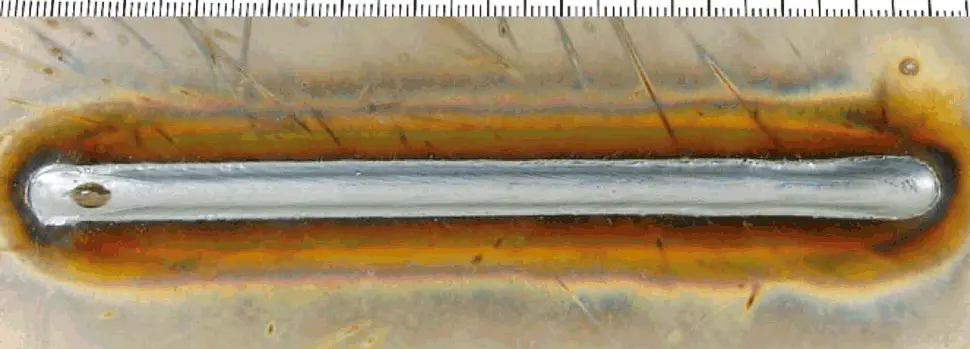

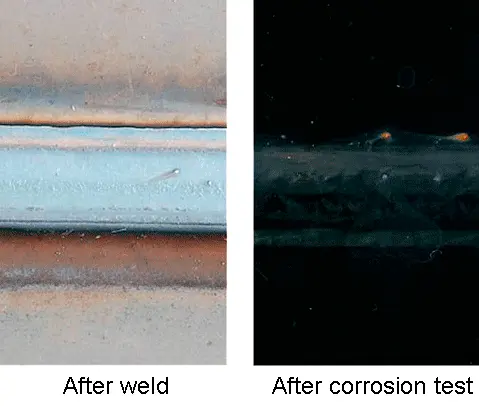

FAMILIARC™ MIX-1TR -the Solid Wire to Improve Electrodeposition Coating Property

- FAMILIARC™ MIX-1TS provides the weld with improved electroposition coating properties with the exsititing equipment.

- Undercut is not likely to occur at the toe of the welded bead even in the welding of sheets with gaps.

- Bead configuration is not likely to become convex even in high speed welding.

- Stable welding with little spatter is possible by selecting optimum welding parameters.

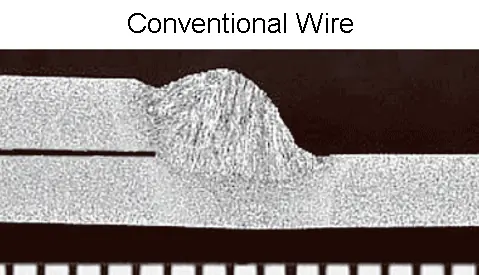

| Wire | Bead appearance comparison after electrodeposition coating (High Tensile Steel, Lap joint) |

|---|---|

| Conventional Wire |

|

| MIX-1TR |

|

- *Wire diameter 1.2mm, Shielding Gas Ar-20%CO2 (Pulse MAG)

| Wire | Bead appearance comparison before electrodeposition coating (High Tensile Steel, Lap joint) |

|---|---|

| Conventional Wire |

|

| MIX-1TR |

|

- *Wire diameter 1.2mm, Shielding Gas Ar-20%CO2 (Pulse MAG)

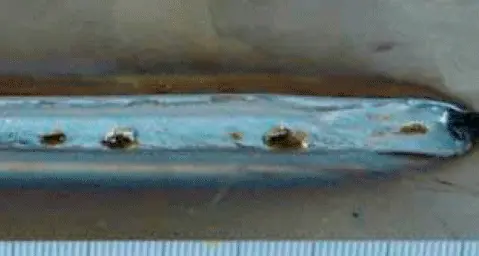

Welding Wire to Achieve Slag-Less welding

FAMILIARC™ SE-A50FS / MIX-50FS

JIS Z 3312 YGW15, Shielding gas: Ar-CO2 Pulse-MAG welding

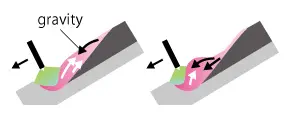

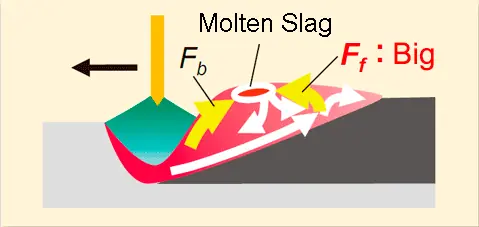

How to Achieve “Slag-Less”

Reduce slag of weldind bead with controlling flow of molten pool and bring slag together at the end of welding bead

Smooth Bead Appearance even at Toe of the Bead

Collect slag on the welding bead by balancing the power affacting molten pool

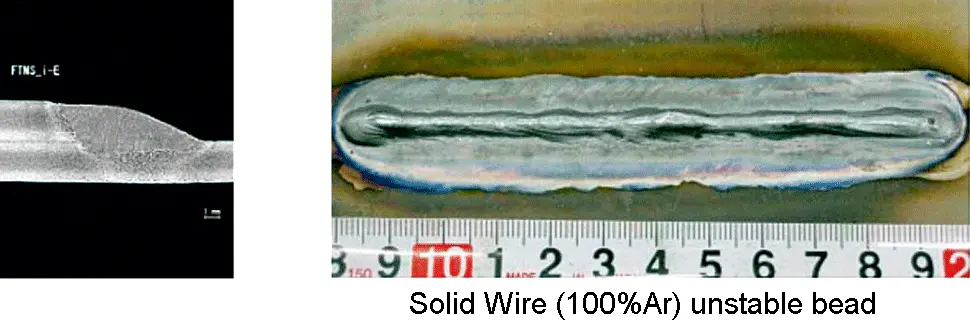

MX-MIG Process FAMILIARC™ MM-1S

Shielding gas: 100%Ar Flux-cored wire for Pulse-MAG

MM-1S enable 100%Ar welding which is unable with solid wire

Minimized Slag Generation

100%Ar welding minimize slag generation with reduction of oxidezed gas

Smooth bead shape even at Toe of the Bead

Corrositon Resistance after Paint Coating

- *Chemical treatment: immerding phosphastisation, Paint coating 25μm, Corrosion test according to JASOM609-91, 60 cycle

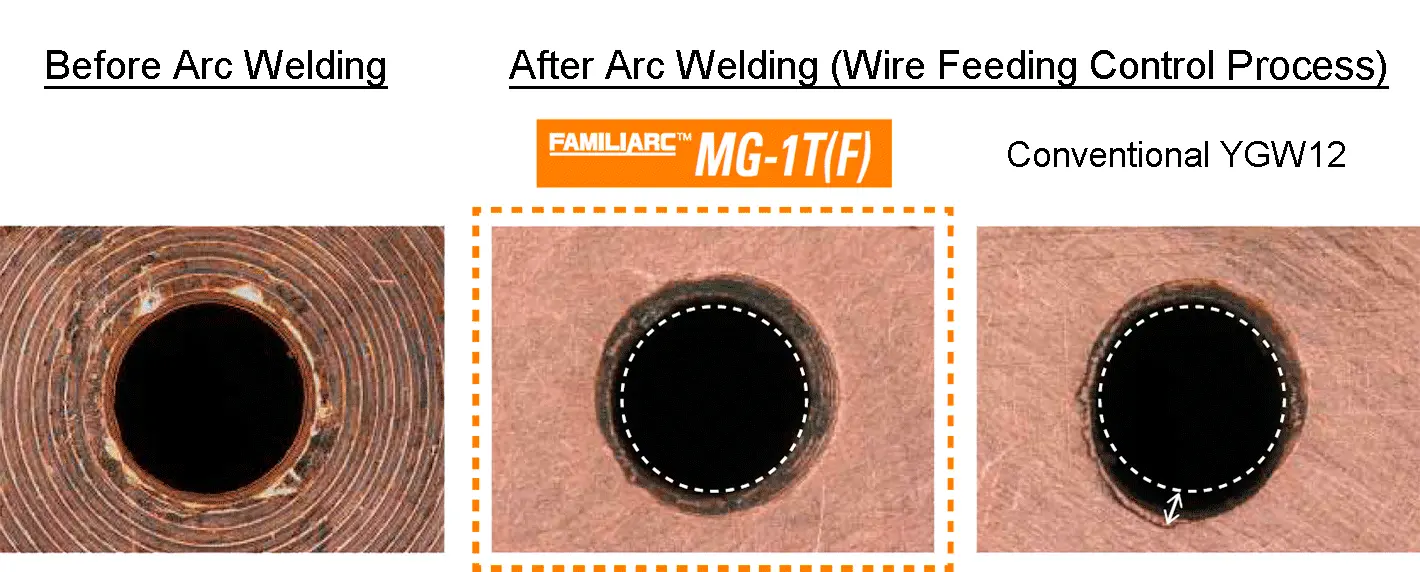

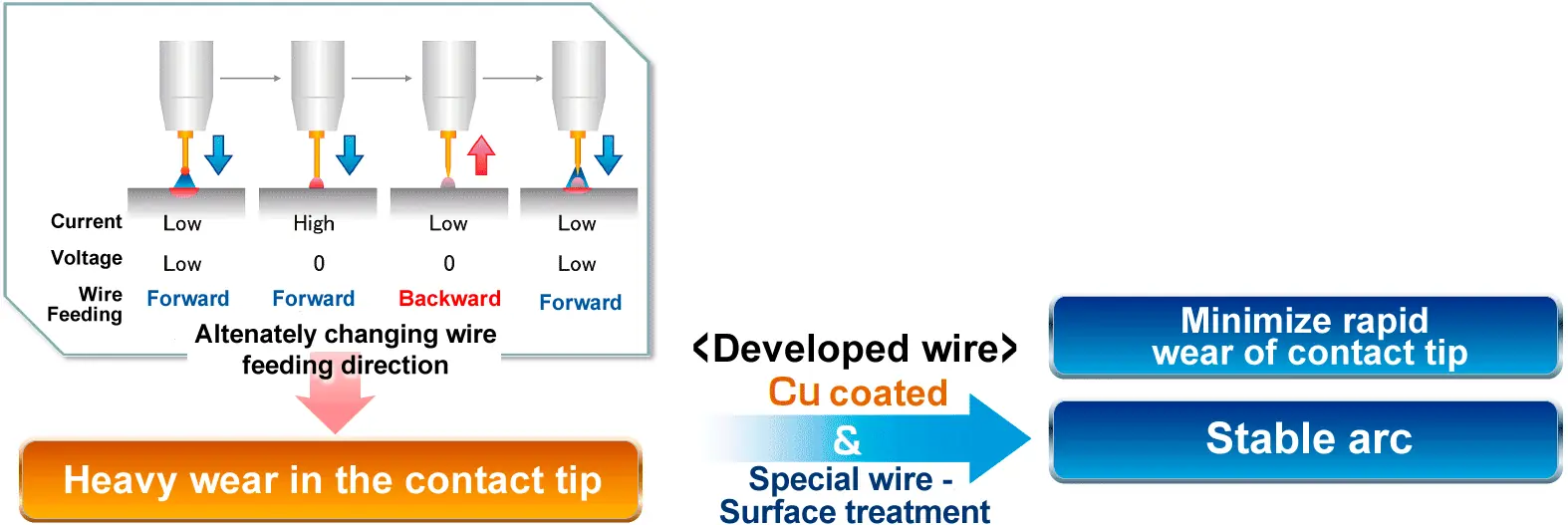

Welding Wire Specially for Wire Feeding Control Process

FAMILIARC™ MG-1T(F)

JIS Z 3312 YGW12 Shielding gas: CO2 & Ar-CO2

Features

- Reduce wear amount of contact tip by special wire-surface treatment

- Stable of weld bead shape with improved wire feeding

- Suitable for thin steel plates such as parts of automobile parts

- *Wire: 1.2mm dia, Welding parameter: 200A-25V-30cpm, 100%CO2, after welding for 1hr continusouly

FAMILIARC™ MG-1S(F): Improve Coating / Painting Property by Reduction of Slag Generation

Reduce slag amount on welding bead which harms painting / coating, by collecting slag at the end of welding bead

Contact Us

You can reach us by clicking the inquiry button.