Boiler

For reduce CO2 emission higher generation efficiency of thermal power plant are required, therefore welding of boiler have to endure high temperature and pressure steam to the turbine. Kobe Steel keep on providing sophisticated welding technology and products to meet stringent specification, such as ferritic high chromium heat-resistant steel and stainless steel.

Table of contents

Welding materials for Coal-fired steam boiler

Welding materials for T/P91, T/P92 steel

Our product line-up per PWHT temperature

| Process / Product (Polarity / AWS Classification) |

Mn+Ni content of deposit -ed metal (wt%) |

Recomm -ended PWHT temp. (℃) |

||||

|---|---|---|---|---|---|---|

| SMAW AWS A5.5: 2014 |

SAW AWS A5.23: 2011 |

GTAW AWS A5.28: 2005 |

GMAW AWS A5.28: 2005 |

|||

| T/P91 (9Cr-1Mo-V-Nb) |

CM-95B91

(DCEP / E9015-B91) CM-96B91

(AC / E9016-B91) |

PF-90B91/

US-90B91

(DCEP / F9PZ-EB91-B91) PF-200S/

US-90B91

(AC / F9PZ-EB91-B91) |

TG-S90B91

(ER90S-B9) |

MG-S90B91

(ER90S-B9) |

≦1.0 (SAW: ≦1.2) |

750~800 |

|

CM-95B9(DCEP)

CM-96B9(AC)

|

PF-90B9/

US-90B9(DCEP)

PF-200S/

US-90B9(AC)

|

TG-S90B9

|

MG-S90B9

|

1.0~1.5 | 750~780 | |

|

CM-9Cb

(AC/DCEP) |

PF-200S/

US-9Cb(AC/DCEP)

|

TG-S9Cb

|

MG-S9Cb

|

1.5~3.0 | 710~760 | |

| T/P92 (9Cr-2W-0.5Mo-VNb) |

CR-12S

(AC/DCEP) |

PF-200S/

US-12CRS(AC)

PF-200S/

US-12CRSD(DCEP)

|

TG-S12CRS

|

MG-S12CRS

|

1.2~2.5 | 740~760 |

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

- *SAW: Flux / Wire

| Type of Steel | Product | Polarity / Shielding Gas |

Typical Chemical Composition of Deposited Metal, wt% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Ni | Cr | Mo | V | Nb | N | Co | Mn+Ni | |||

| T/P91 (9Cr-1Mo-V-Nb) |

CM-95B91

|

DCEP | 0.10 | 0.20 | 0.64 | 0.10 | 8.20 | 0.90 | 0.20 | 0.05 | 0.03 | 0.40 | 0.74 |

|

PF-90B91/

US-90B91

|

DCEP | 0.08 | 0.17 | 0.89 | 0.14 | 8.62 | 0.98 | 0.18 | 0.03 | 0.05 | 0.31 | 1.03 | |

|

PF-200S/

US-90B91

|

AC | 0.08 | 0.15 | 0.85 | 0.12 | 8.64 | 0.98 | 0.18 | 0.03 | 0.05 | 0.32 | 0.97 | |

|

TG-S90B91

|

DCEN/ 100%Ar |

0.10 | 0.26 | 0.71 | 0.13 | 8.50 | 0.97 | 0.19 | 0.05 | 0.04 | 0.38 | 0.84 | |

|

MG-S90B91

|

DCEP/ Ar-5%CO2 |

0.12 | 0.24 | 0.64 | 0.15 | 8.47 | 0.98 | 0.18 | 0.05 | 0.04 | 0.41 | 0.79 | |

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

| Type of Steel | Product | Polarity / Shielding Gas |

Typical Mechanical Properties of Deposited Metal | ||||

|---|---|---|---|---|---|---|---|

| 0.2% Yield Strength (MPa) |

Tensile Strength (MPa) |

vE20℃ (J) |

PWHT (℃/h) |

Ac1 (℃) |

|||

| T/P91 (9Cr-1Mo-V-Nb) |

CM-95B91

|

DCEP | 593 | 731 | 50 | 767/2 | 809 |

|

PF-90B91/

US-90B91

|

DCEP | 585 | 722 | 71 | 760/2 | 788 | |

|

PF-200S/

US-90B91

|

AC | 563 | 722 | 69 | 760/2 | 794 | |

|

TG-S90B91

|

DCEN/100%Ar | 579 | 713 | 216 | 760/2 | 820 | |

|

MG-S90B91

|

DCEP/Ar-5%CO2 | 529 | 689 | 74 | 760/8 | 813 | |

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

- *Recommended PWHT temp.

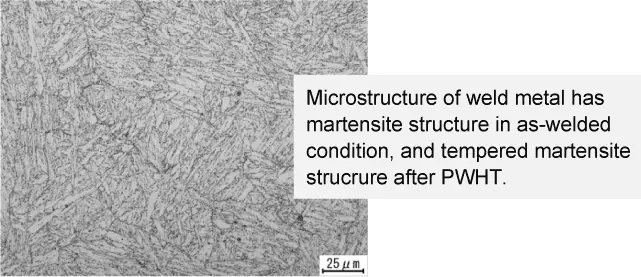

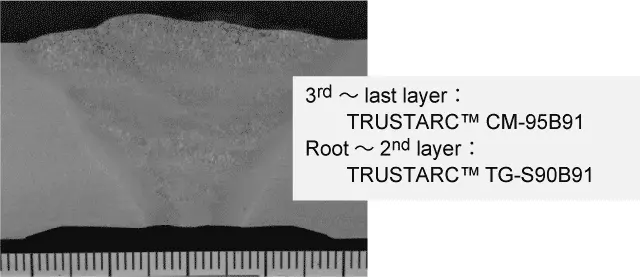

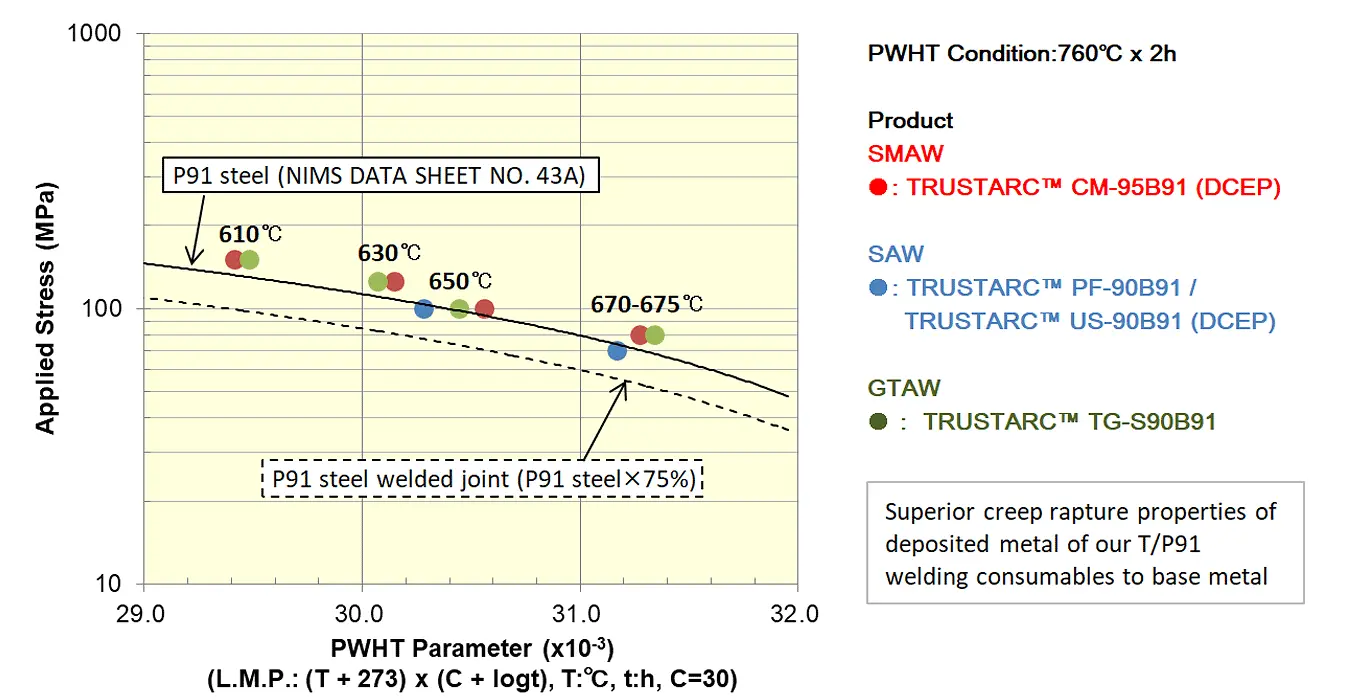

Typical creep rupture properties of deposted metal

Welding Materials for Boiler of Thermal Power Plant

Line-up for Thermal Power Welding - SMAW

| Type of Steel | DCEP | AC | ||

|---|---|---|---|---|

| AWS Class. | Product | AWS Class. | Product | |

| P1 / T1 (0.5Mo) |

E7016-A1 |

CM-A76

CM-B76

|

E7016-A1 |

CM-A76

CM-B76

|

| P2 / T2 | E8016-B1 |

CM-B86

|

– | – |

| P11 / T11 (1.25Cr-0.5Mo) |

E7015-B2L |

CM-B95

|

– | – |

| E8016-B2 | E8016-B2 |

CM-A96

CM-A96MB

|

||

| E8018-B2 |

CM-B98

|

E8018-B2 |

CM-B98

|

|

| P22 / T22 (2.25Cr-Mo) |

E8015-B3L |

CM-B105

|

– | – |

| E9015-B3 |

CM-B105D

|

– | – | |

| E9016-B3 | E9016-B3 |

CM-A106N

|

||

| E9018-B3 |

CM-B108

|

E9018-B3 |

CM-B108

|

|

| P23 / T23 | E9016-G | E9016-G |

CM-2CW

|

|

| P91 / T91 | E9015-B91 | E9016-B91 |

CM-96B91

|

|

| E9016-G | E9016-G |

CM-9Cb

|

||

| P92 / T92 P122 / T122 |

E9016-G | – |

CR-12S

|

|

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

Line-up for Thermal Power Welding - SAW

| Type of Steel | DCEP | AC | ||

|---|---|---|---|---|

| AWS Class. | Product | AWS Class. | Product | |

| P1 / T1 (0.5Mo) |

– | – | F8P6-EA3-A3(F9A6) |

MF-38 / US-40

|

| F8P6-EA4-A4(F8A4) |

MF-38 / US-A4

|

|||

| F8P6-EG-A4(F8A4) |

MF-38 / US-49

|

|||

| P11 / T11 (1.25Cr-0.5Mo) |

F7PZ-EB2-B2 | F7PZ-EB2-B2 |

G-80 / US-B2

|

|

| F7PZ-EG-B2 |

MF-29A / US-511

|

F7PZ-EG-B2 |

MF-29A / US-511

|

|

| F8P2-EG-B2 | F8P2-EG-B2 |

PF-200 / US-511N

|

||

| P23 / T23 | – |

MF-29A / US-2CW

|

– | – |

| P91 / T91 (9Cr) |

F8PZ-EB91-B91 |

PF-90B91 US-90B91

|

F8PZ-EB91-B91 | |

| P92 / T92 P122 / T122 |

– |

PF-200S / US-12CRSD

|

– | – |

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

Line-up for Thermal Power Welding – GMAW, GTAW

| Type of Steel | AWS Class. | FCAW |

|---|---|---|

| P11/T11 (1.25Cr-0.5Mo) | E81T1-B2C E81T1-B2M |

|

| P22/T22 (2.25Cr-1Mo) | E91T1-B3C E91T1-B3M |

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

| Type of Steel | AWS Class. | Product | |

|---|---|---|---|

| GMAW | GTAW | ||

| P1/T1 (0.5Mo) |

ER70S-A1 |

MG-S70SA1

|

TG-S70SA1

|

| ER80S-G |

MG-SM

|

TG-SM

|

|

| P2 / T2 | ER80S-G |

MG-CM

|

– |

| – | – |

TG-SCM

|

|

| P11 / T11 (1.25Cr-0.5Mo) |

ER80S-B2 | ||

| ER80S-G |

MG-S1CM

|

||

| P22 / T22 (2.25Cr-1Mo) |

ER90S-B3 | – | |

| ER90S-G |

MG-S2CM

|

||

| P23 / T23 | ER90S-G |

MG-S2CW

|

TG-S2CW

|

| P91 / T91 (9Cr) |

ER90S-B9 | ||

| ER90S-G | |||

| P92 / T92 P122 / T122 |

ER90S-G | ||

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

- *Single pass only

Welding Materials for Austenitic Heat-resistant Stainless Steel

Line-up for Ultra Super Critical piping

| Product | Applicable Bese Metal | Type of Filler Metal | Chemistry of Filler Metal |

|---|---|---|---|

| TG-Super304H | SUPER304H® ASTM A213 S30432 |

Filler Wire for GTAW | 19Cr-16Ni-3Cu-3Mn-2W-0.5Nb-0.2N-0.1C |

| NC-B1AS | TEMPALOY®AA-1 ASTM A213 S30434 |

Covered Electrode for SMAW | 19Cr-14Ni-3Cu-2.4Mo-1.6Mn-0.4Nb-0.13C |

| TG-S1AS | Filler Wire for GTAW | ||

| NC-B3A | TEMPALOY®A-3 ASTM A213 S30942 |

Covered Electrode for SMAW | 22Cr-16Ni-1.4Mn-0.6Mb-0.13N |

| TG-S3A | Filler Wire for GTAW |

- *stands for FAMILIARC™, stands for TRUSTARC™, and stands for PREMIARC™.

- *Super304H is registered trade mark of Nippon Steel & Sumitomo metal Corporation.

- *TEMPALOY is registerd trade mark of JFE Steel Corporation.

Contact Us

You can reach us by clicking the inquiry button.