Shipbuilding

Our Welding business has been developing with shipbuilding in Japan.We keep on proposing welding solutions to shipyards all over the world.

Table of contents

- KOBELCO Welding Solutions for Automation with Higher Quality & Efficiency

- Welding Process to improve productivity

- TRIFARC™ (high speed triple tandem one pool method) for Horizontal Fillet Welding

- HT-MAG™ Process: An effective porosity-reduction method for welding primer-coated steel plates

- FCB™ process and equipment for butt joint of large plates

- RF™ process and equipment

- SEGARC™ - for vertical upward welding

- Automated Horizontal Butt Welding Ishimatsu × FAMILIARC™ MX-100ER

- FAMILIARC™ DW-100V - Improved vertical-up performance

- Our proposal and progress on horizontal fillet welding

- Welding in Sub-Assembly to Assembly Stage

- Welding in Erection Stage

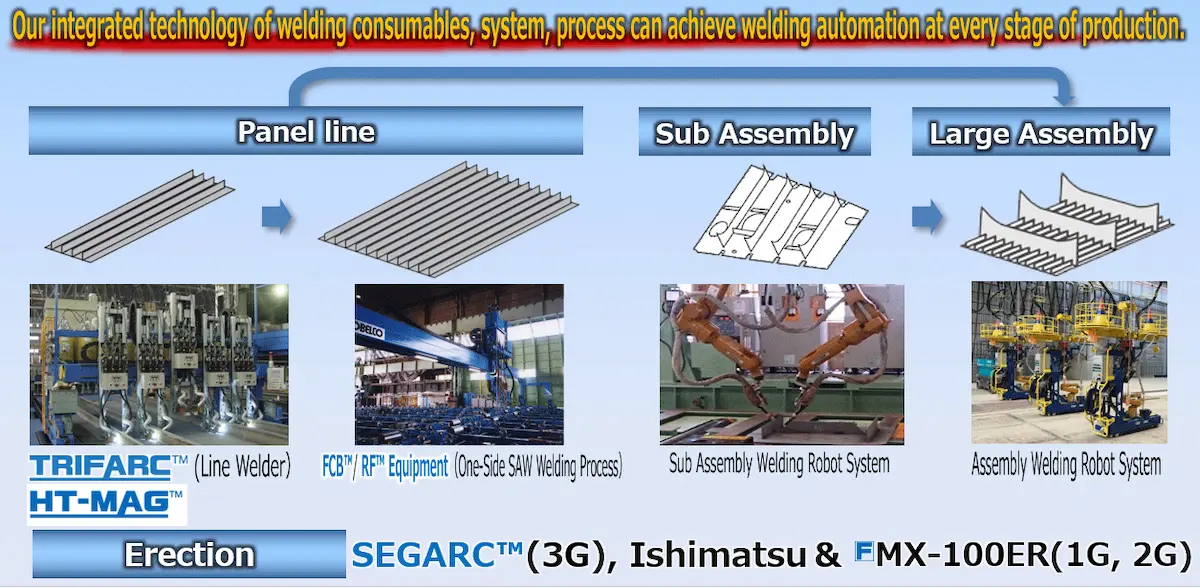

KOBELCO Welding Solutions for Automation with Higher Quality & Efficiency

Our Line-ups for Welding Automation Technology by Stage

Integrated technolgy of welding consumables, welding system and welding process enables welding automation at every stage.

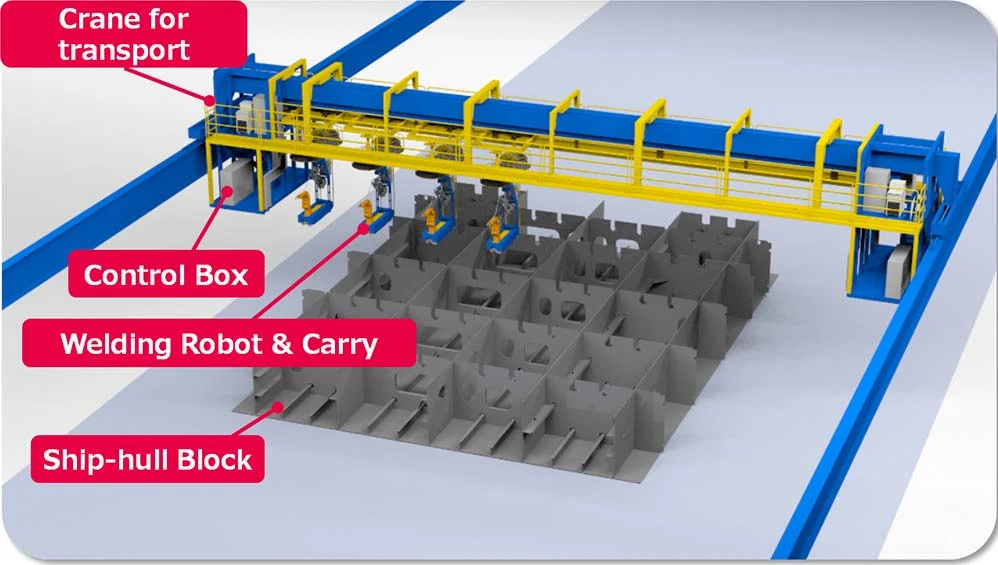

Large Assembly Welding System

- Automatic vertical upward and horizontal fillet welding within the confined space of ship hull block made possible by a miniature ARCMAN™ robot mounted on a robot carry.

- By integrating the data from 3D models with our automatic programming soft "SMART TEACHNG™", manual programming is not required. SMART TEACHING™ can establish program at around 3minitues for about 400 welding joints of the ship hull block

- 30% improvement in welding speed in vertical upward welding over connventional all-positional welding wire whilist keeping the weldability of horizontal fillet welding using FAMILIARC™ DW-100R special FCAW.

System Configuration

Welding parts where Large Assembli Welding System is applied

Introduction Movie

FAMILIARC™ DW-100R ‐ Specially designed for Large Assembly Welding Robot System

Achieves both efficient vertical upward welding and beautiful bead appearance in horizontal fillet welding

Welding Process to improve productivity

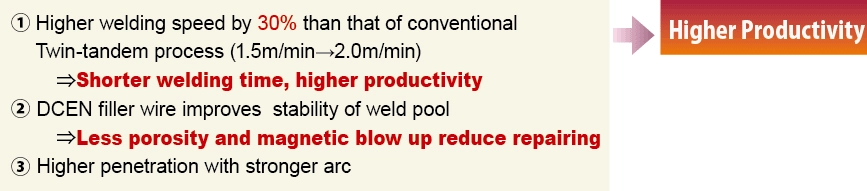

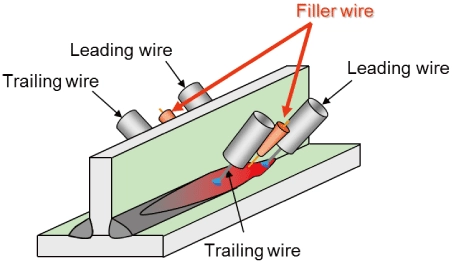

TRIFARC™ (high speed triple tandem one pool method) for Horizontal Fillet Welding

Torch arrangement

Leading & trailing wire: FAMILIARC™ MX-200HS Filler wire: FAMILIARC™ MG-1HS

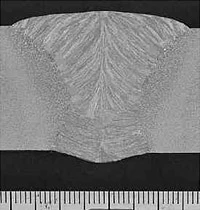

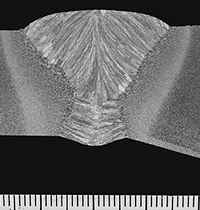

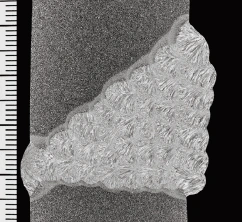

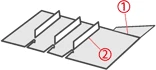

Bead appearance and shape

Welding parameter

| L: | 560A-38V |

|---|---|

| T: | 440A-36V |

| Filler wire: | 80A (DC-EN) |

| Travel speed: | 2.0m/min |

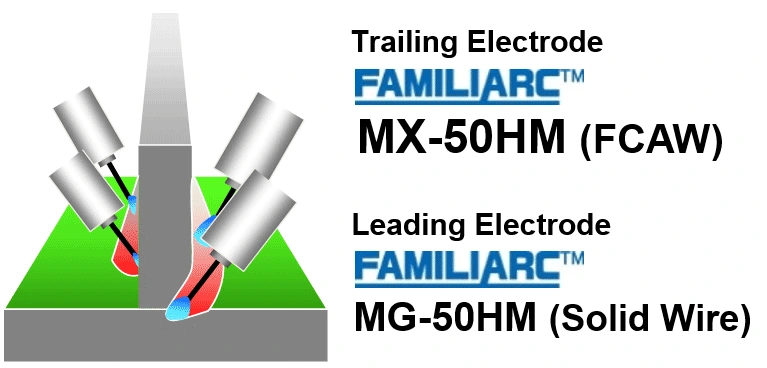

HT-MAG™ Process: An effective porosity-reduction method for welding primer-coated steel plates

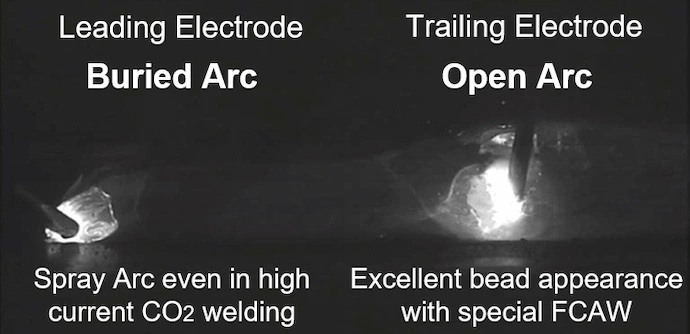

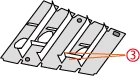

Configuration of HT-MAG™

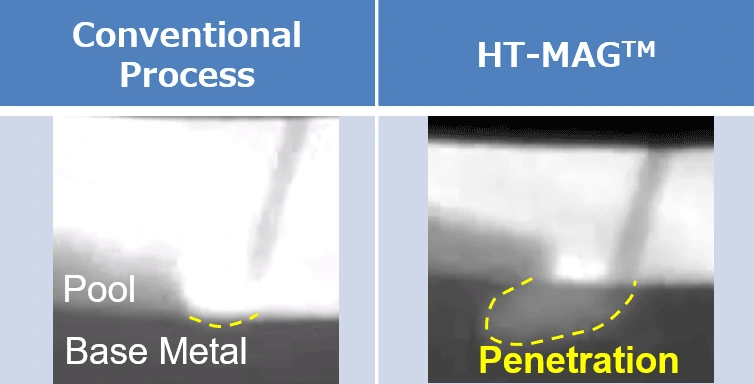

Penetration of leading electrode

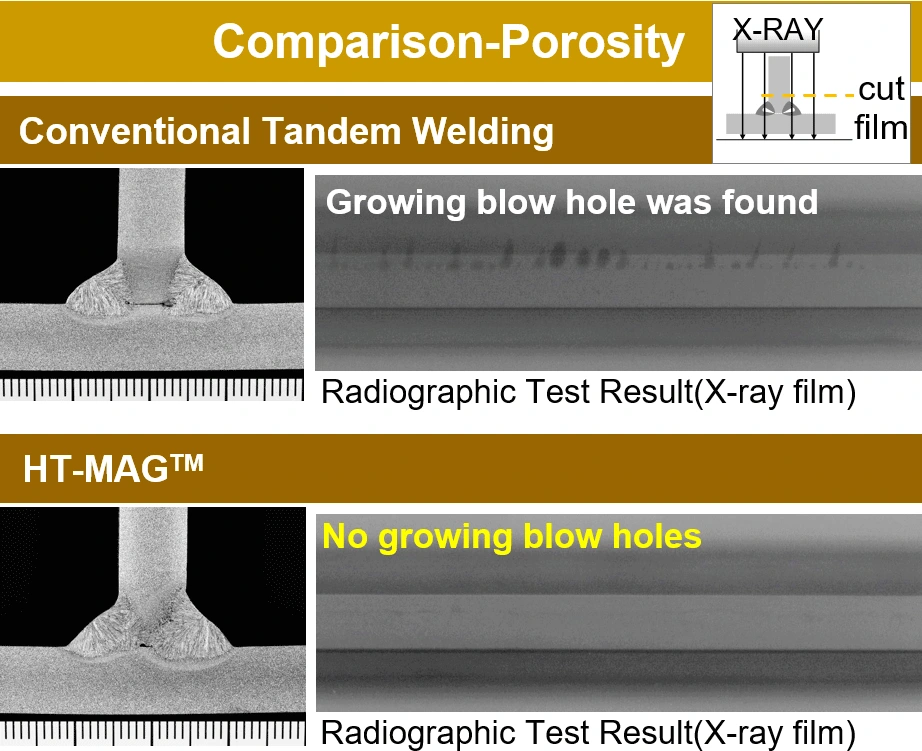

Features of HT-MAG™

- Deep penetration obtained with buried arc of leading electrode can reduce porosity in welding primer coated steel plate.

- Low Spatter generation even in CO2 tandem welding

Shipping Approvals

| NK | ABS | DNV-GL | LR | BV |

|---|---|---|---|---|

| KAW53Y40MG(C) | 3Y400A | ⅢYM | 3YM | A3Y40M |

Click the link below for the details of HT-MAG™ at KOBELCO Global Website

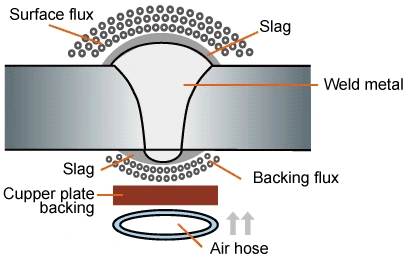

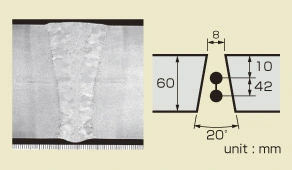

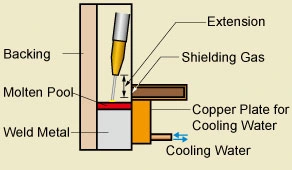

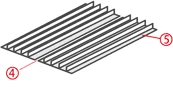

FCB™ process and equipment for butt joint of large plates

- Plate thickness

25mm

- Process

4 electrodes FCB™ one-side SAW

- Travel speed

800mm/min.

Features

- Consistent reverse bead at high welding current

- Applicable for 10 to 40mm plate thickness. (3 electrodes: up to 35 mm, 4 electrodes: up to 40 mm)

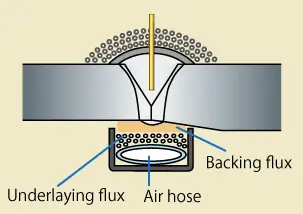

RF™ process and equipment

Features

- Easy to make good plate-to-backing contact, particularly in joints with misalignment and tapered transition, and in thin plate

Welding parameter

| Plate thickness | 20mm×50mm |

|---|---|

| Taper | 1-to-3 taper |

| L | 1400A-26V |

| T1 | 1000A-40V |

| T2 | 1100A-46V |

| Travel speed | 80cm/min |

SEGARC™ - for vertical upward welding

- SEGARC™ - extremely efficient welding process in vertical upward

- High deposition rate, 180cm/min at 380A

- Applicable to inclined upward welding

- Optimum oscillation of welding torch enables one pass welding up to 65 mm plate thickness

Welding parameter

| Current (A) |

Voltage (V) |

Travel speed (cm/min) |

Heat input current (KJ/cm) |

|---|---|---|---|

| 400 | 43 | 2.6 | 397 |

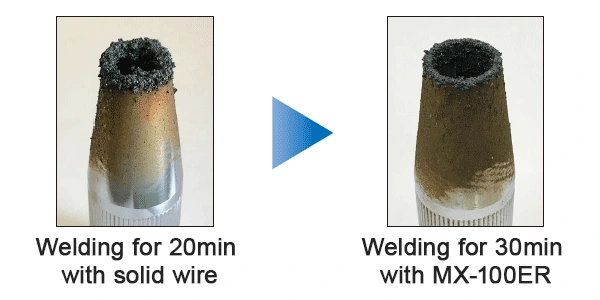

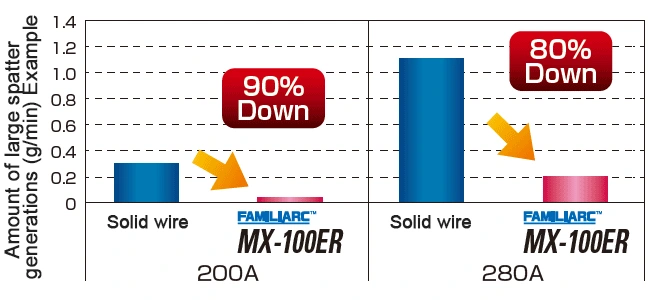

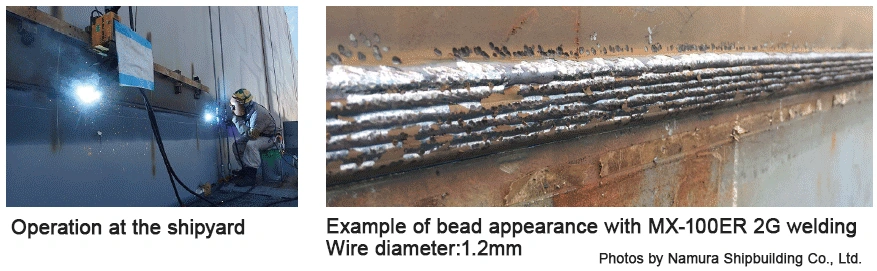

Automated Horizontal Butt Welding Ishimatsu × FAMILIARC™ MX-100ER

Features

- Optimized welding parameter is preset on compact & portable welding robot ISHIMATSU and excellent bead appearance can be obtained.

- Small amount spatter generation with FAMILIARC™ MX-100ER reduces nozzle replace and cleaning time and the risk of insufficient shielding gas flow.

- Slag removals is not necessary for 2 to 3 pass due to little slag generations.

Shipping Approvals

| NK | ABS | BV | DNV-GL | LR |

|---|---|---|---|---|

| KSW53Y40G(C)H5 | 3Y400SAH5 | SA3Y40MH5 | ⅢY40MS (H5) | 3Y40H5 |

Low Spatter Generation

High Efficient Horizontal Welding with Ishimatsu

FAMILIARC™ MX-100ER

Horizontal Welding (2G)

- Plate thickness

32mm

- Wire diameter

1.2mm

- Welding Sequence

9 layers 34 pass

- Heat input

0.8kJ/mm

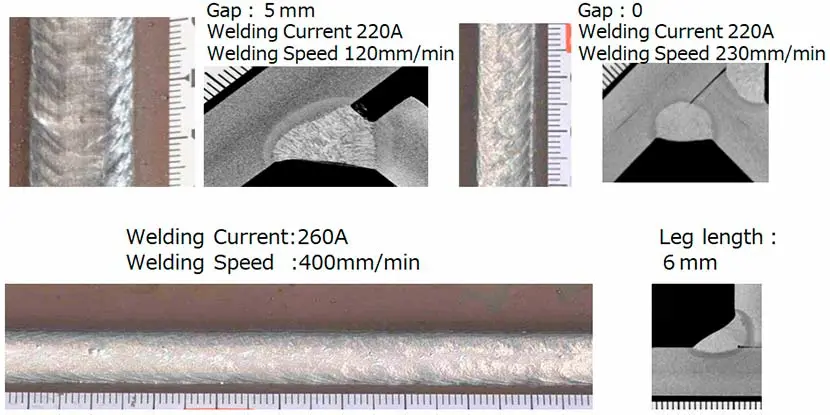

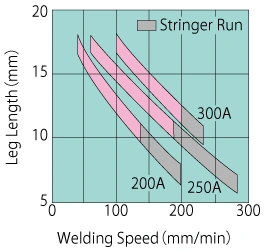

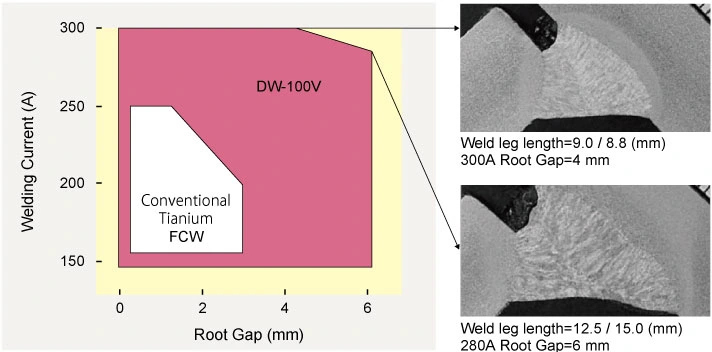

FAMILIARC™ DW-100V - Improved vertical-up performance

Features

- FAMILIARC™ DW-100V enables an high current vertical-up welding at 250 to 300A.

- Stringer run at vertical up welding

- Superior resistance to root gap

Relationship between leg length and travel speed

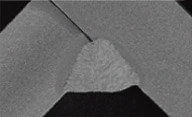

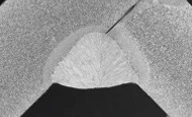

Macro structure (Example)

Welding parameter: 230A-360mm/min

Welding parameter: 250A-320mm/min

Welding parameter: 280A-200mm/min

Relationship between root gap and welding current

Specification

| Specification | Shipping approvals | |

|---|---|---|

| JIS | AWS | NK, ABS, LR, DNV, BV, GL, CCS |

| Z 3313 T 49J 0 T1-1 C A-U | A5.20 E71T-1C | |

Our proposal and progress on horizontal fillet welding

Welding wire for single pass

| Product | Porosity Resistance (Applicable travel speed) |

Sputter generation | Bead shape / appearance | HF Range of leg length |

|---|---|---|---|---|

| MX-200 | ≦600mm/min | Good | Good | 4 to 8mm |

|

≦600mm/min

|

Better

|

Better

|

5 to 9mm

|

|

|

≦700mm/min

|

Good

|

Good to Better

|

5 to 9mm

|

|

| DW-200 | ≦500mm/min | Good | Better | 6 to 10mm |

- *stands for FAMILIARC™, stands for TRUSTARC™, andstands for PREMIARC™.

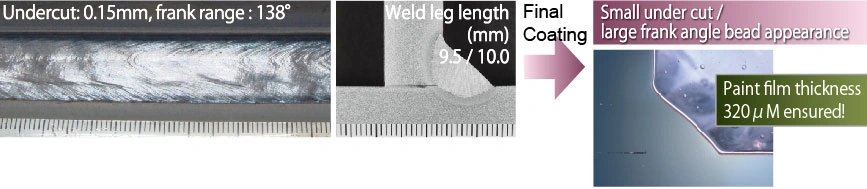

FAMILIARC™ MX-200F - Large leg length with smooth bead appearance

- Applicable for 5 to 9mm weld leg length

- Smooth bead shape with large leg length

- Less undercut at upper leg length ensure required paint film thickness by PSPC

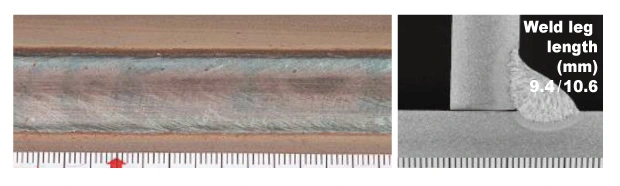

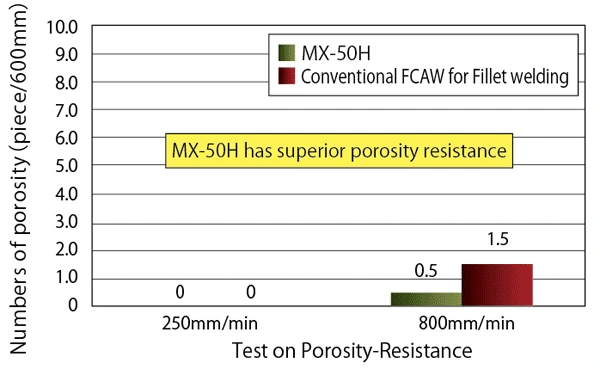

FAMILIARC™ MX-50H - Large leg length with high travel speed

- 5 to 9mm weld leg length available

- Smooth bead shape with large leg length

- Excellent slag removal and shinny bead appearance

- Excellent porosity resistance

Plate 20mm×50mm 12mmt. inorganic zinc primer, thickness: 30μm

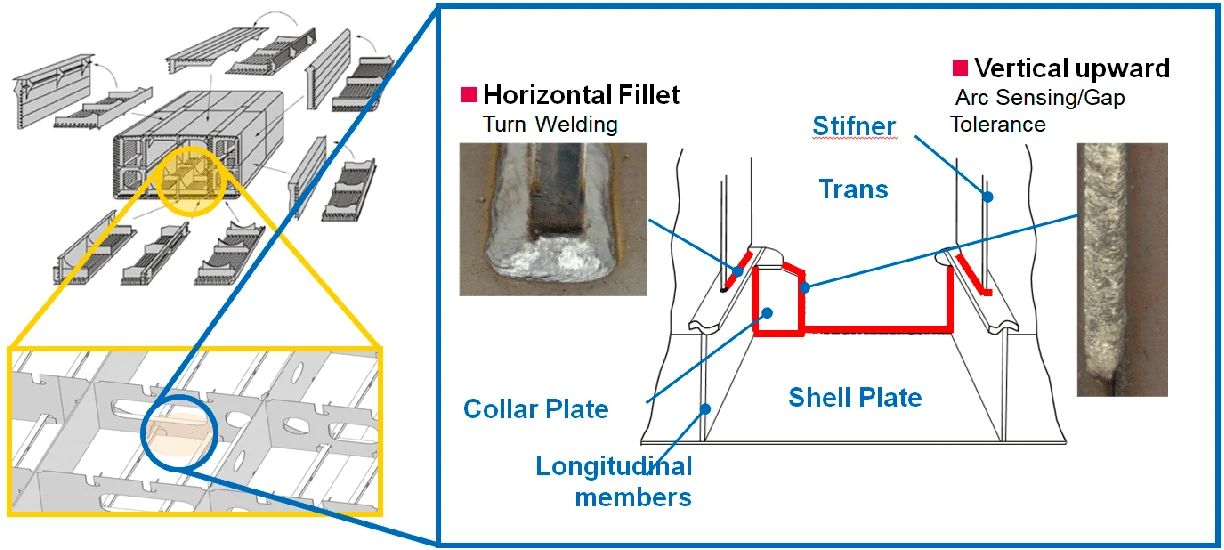

Welding in Sub-Assembly to Assembly Stage

| Member and Joint | Welding Position | Welding Process | Typical Welding Consumables | Remarks | |

|---|---|---|---|---|---|

|

Built-up Longitudinal | HF | GMAW (MAG) |

MX-(Z)200

|

Welding carridge |

|

MX-200H (X2)

|

twin-tandem one pool method | ||||

|

MX-200HS (x2) /

MG-1HS

|

- *stands for FAMILIARC™, stands for TRUSTARC™, andstands for PREMIARC™.

| No. | Member and Joint | Welding Position | Welding Process | Typical Welding Consumables | Remarks | |

|---|---|---|---|---|---|---|

|

① | Butt joint (Flat Panel) | Flat | SAW (Double-side) |

US-36 /

PF-H55E,

US-36,

PF-H52

|

|

| ② | Stiffner | HF | GMAW (MAG) |

MX-(Z)200,

MX-50H,

DW-200

|

Welding carridge | |

| Gravity welding (SMAW) |

LT-Z-27,

LT-B50,

LT-B52A

|

Gravity welding | ||||

|

③ | HF | GMAW (MAG) |

DW-(Z)100,

|

Robot applied | |

|

④ | Flat |

US-36 /

PF-I55E,

PF-H55EM

|

Wire & Surface Flux | ||

|

PF-I50R

|

Backing Flux | |||||

|

US-36 /

PF-I55E

|

Wire & Surface Flux | |||||

|

RF-1 /

No.1296

|

Backing Flux / Underlay Flux |

|||||

| ⑤ | HF | GMAW (MAG) |

MX-(Z)200

|

Welding carridge | ||

|

MX-200H (x2)

|

twin-tandem one pool method | |||||

|

MX-200HS(x2) /

MG-1HS

|

||||||

|

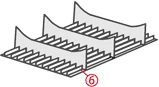

⑥ | HF, V | GMAW (MAG) |

DW-(Z)100

|

Robot applied | |

|

DW-(Z)100,

|

Semi-auto | |||||

|

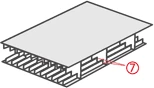

⑦ | Inner Double-hull/Fillet | HF, V | GMAW (MAG) |

DW-(Z)100

|

Semi-auto |

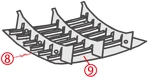

|

⑧ | Bilge/Butt | Flat | FAB (One side SAW) |

US-36 /

PF-I52E /

FA-B1 /

RR-2

|

FAB method |

| GMAW (One side) |

DW-(Z)100 /

FB-B3T

|

Semi-auto | ||||

| GMAW (One side) |

MG-50D /

FB-B3A

|

Automatic | ||||

| ⑨ | Horizontal | HF | GMAW (MAG) |

MX-(Z)200

|

Welding carridge |

- *stands for FAMILIARC™, stands for TRUSTARC™, andstands for PREMIARC™.

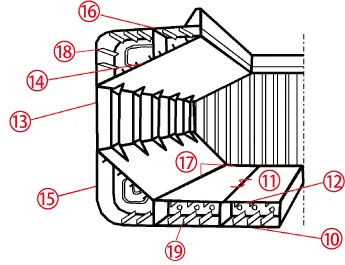

Welding in Erection Stage

| No. | Member and Joint | Welding Position | Welding Process | Typical welding consumables | Remarks |

|---|---|---|---|---|---|

| ⑩ | Bottom shell / Butt | Flat | GMAW (One side) |

DW-(Z)100 / FB-B3T

|

Semi-auto |

| ⑪ | Tank Top (Seam, Longitudnal) |

Flat | FAB (One side SAW) |

US-36 /

PF-I52E /

FA-B1 /

RR-2

|

FAB method |

| GMAW (One side) |

DW-(Z)100 /

FB-B3T

|

Semi-auto | |||

| GMAW (One side) |

MG-50D /

FB-B3A

|

Automatic | |||

| ⑫ | Tank Top (butt, trans) |

Flat | GMAW (One side) +SAW |

DW-(Z)100 /

FB-B3T + US-36 /

PF-H55E

|

Semi-auto + Auto |

| GMAW (One side) |

DW-(Z)100 /

FB-B3T

|

Semi-auto | |||

| ⑬ | Side shell / butt | Vertical | EGW |

DW-S43G /

KL-4

|

|

| GMAW (One side) |

DW-(Z)100 /

FB-B3T

|

Semi-auto | |||

| ⑭ | Top side tank / butt | Flat | GMAW (One side) |

DW-(Z)100 /

FB-B3T

|

Semi-auto |

| ⑮ | Builge hopper / butt | Vertical | GMAW (One side) |

DW-(Z)100 /

FB-B3T

|

Semi-auto |

| ⑯ | Hatch combing rail (Stainless) / Fillet |

HF | GMAW (MAG) |

PREMIARC™ DW-309,

PREMIARC™ DW-309LP

|

Semi-auto |

| GMAW (MAG) |

PREMIARC™ DW-309,

PREMIARC™ DW-309LP

|

Welding carridge | |||

| ⑰ | Upper deck / butt | Flat | GMAW (One side) + SAW (Double-side) |

DW-(Z)100 /

FB-B3T

+ US-36 /

PF-H55E

|

Semi-auto + Auto |

| ⑱ | Tank top / fillet | HF | GMAW (MAG) |

DW-(Z)100

|

Semi-auto |

|

MX-Z200

|

Welding carridge | ||||

| ⑲ | Long / butt | Flat, V | GMAW (One side) |

DW-(Z)100 /

FB-B3T

|

Semi-auto |

- *stands for FAMILIARC™, stands for TRUSTARC™, andstands for PREMIARC™.

Contact Us

You can reach us by clicking the inquiry button.