Aluminum Alloy Clad Sheets for Automotive Heat Exchangers and Battery Coolers

Aluminum alloy clad sheets meet various requirements

Clad sheets consisting of multiple aluminum alloys are used for automotive heat exchangers, not just for thermal conductivity, but also for a diverse range of properties including formability, brazeability, strength, and corrosion resistance. Kobe Steel develops and provides clad sheets with excellent properties that meet customer requirements, particularly thin gauge and high strength, high corrsion resistance. We will also provide solutions to the needs of society by focusing on the development of low-carbon (recycled) sheets as an initiative directed to achieving carbon neutrality.

Features

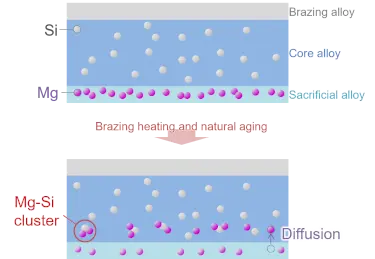

High strength achieved through Mg diffusion

Jointly developed by DENSO. Received the 28th Oyamada Memorial Award from the Japan Institute of Light Metals.

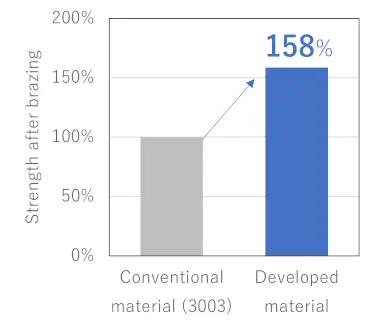

- Approx. 1.5 times the strength of conventional materials after brazing

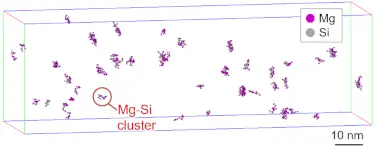

- Achieves Mg-Si cluster hardening by diffusing Mg of liner alloy (sacrificial alloy) on core alloy including Si

- Good corrosion resistance and brazability equivalent to conventional materials

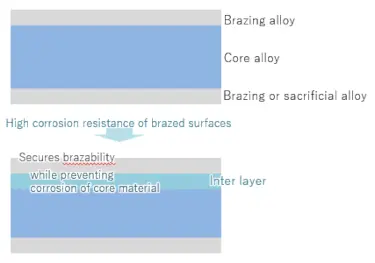

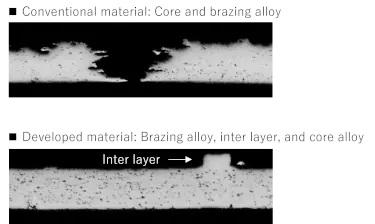

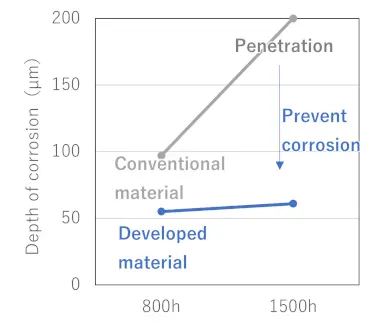

High corrosion resistance of brazed surfaces (balanced design for brazability and corrosion resistance)

- Corrosion resistance is more than three times that of brazing clad material, and equivalent to or better than 7072 sacrificial clad sheet.

- Good corrosion resistance on the cooling water side as well as the air-exposed side

- Brazability and strength after brazing is equivalent to or better than conventional materials.

Kobe Steel’s Typical Aluminum Alloy Clad Sheet Products

Primary product applications

- Tube stock

- Plate stock

- Fin stock

- Plate stock for battery coolers

Brazing alloys

- 4343

- 4045

- 4047

- 4045MOD Al-Si-X-Y

Core alloys

- 3003

- 3N33

- 3003MOD

Sacrificial, inter layer alloys

- 7072

- 7072MOD Al-Si-Zn

- 1100

- 3003MOD Al-Si-Mn-Zn

Contact Us

You can reach us by clicking the inquiry button.