High Precision Aluminum Alloy Plate for Precision Machining ALJADE™

ALJADE™ is a 5052 high-precision aluminum alloy plate with greatly improved flatness and thickness tolerance, as well as lower residual stress compared to JIS standards.

By reducing cutting time, annealing after processing, and increasing yields, ALJADE™ assists customers in reducing costs.

Features

- Improved manufacturing processes offer increased flatness.

- Our superior rolling technology offers approx. 1/10 the JIS standard accuracy for thickness.

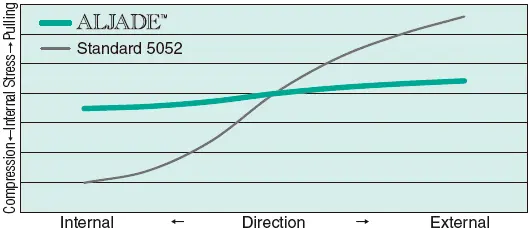

- Our distinctive heat treatment process greatly reduces internal residual stress.

Applications

- Semiconductor manufacturing equipment

- LCD manufacturing equipment

- Solar panel manufacturing equipment

- Robots

- Medical equipment

- OA equipment

- Optical equipment

- Various molds & tools

Residual Stress

Quality / Refining / Composition

A5052P-H112

(Unit: Wt/%)

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Al |

|---|---|---|---|---|---|---|---|

| ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2-2.8 | 0.15-0.35 | ≤0.10 | Remainder |

Thickness Accuracy

(Unit: mm)

| Thickness | 4 | 5 | 6 | 6<-≤12 | 12<-≤16 | 16<-≤19 | 19<-≤21 | 21<-≤22 |

|---|---|---|---|---|---|---|---|---|

| ALJADE™ Tolerance |

±0.06 | ±0.07 | ±0.08 | ±0.10 | ±0.15 | ±0.18 | ±0.20 | ±0.22 |

Reference (Unit: mm)

| Thickness | 4≤-≤5 | 5<-≤6 | 6<-≤8 | 8<-≤11 | 11<-≤12 | 12<-≤15 | 15<-≤16 |

|---|---|---|---|---|---|---|---|

| JIS Tolerance | ±0.35 | ±0.45 | ±0.50 | ±0.60 | ±0.70 | ||

(Unit: mm)

| Thickness | 22<-≤27 | 27<-≤35 | 35<-≤49 | 49<-≤54 | 54<-≤64 | 64<-≤74 | 74<-≤100 |

|---|---|---|---|---|---|---|---|

| ALJADE™ Tolerance |

±0.25 | ±0.30 | ±0.40 | ±0.50 | ±0.60 | ±0.65 | ±0.85 |

Reference (Unit: mm)

| Thickness | 16<-≤20 | 20<-≤22 | 22<-≤29 | 29<-≤35 | 35<-≤40 | 40<-≤45 | 45<-≤50 |

|---|---|---|---|---|---|---|---|

| JIS Tolerance | ±0.80 | ±0.90 | ±1.0 | ±1.1 | ±1.3 | ||

Surface Flatness

- ALJADE™

Thickness 4-50 mm: 0.2 mm or less/M

Thickness 50<-70 mm: 0.6 mm or less/M

Thickness 70<-100 mm: 0.8 mm or less/M

Mechanical Properties (Typical Values)

| Thickness(mm) | Tensile strength (N/mm2) | Yield strength (N/mm2) | Elongation (%) |

|---|---|---|---|

| 4≤-≤13 | 226 | 132 | 24 |

| 13<-≤100 | 203 | 96 | 35 |

Product Size

| Thickness | Width × Length |

|---|---|

| 4-100 | 1,525×3,050 |

Catalog

- Japanese

- English

Contact Us

You can reach us by clicking the inquiry button.