Pre-Coated Aluminum Fin Stock for Heat Exchangers

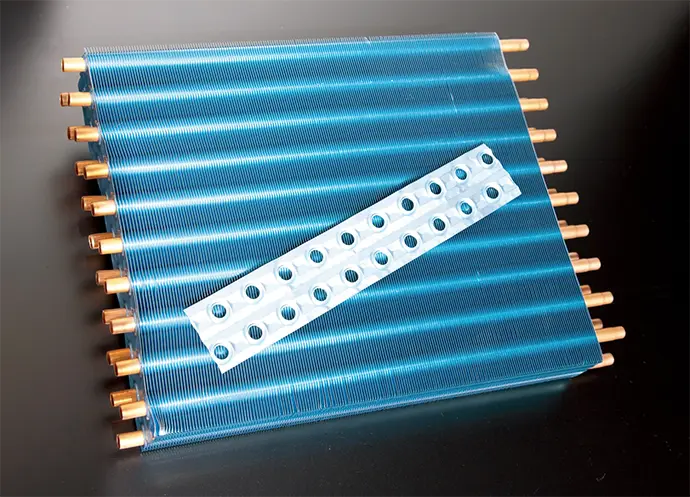

Aluminum fin stock, with its excellent thermal conductivity, is utilized in heat exchangers for room/ package air conditioners and large refrigerators.

Kobe Steel meets customers' needs for multifunctional fin stock with our superior coating technologies.

Features

Our product lineup offers varieties of properties that are essential for heat excahngers.

(1) Hydrophilicity

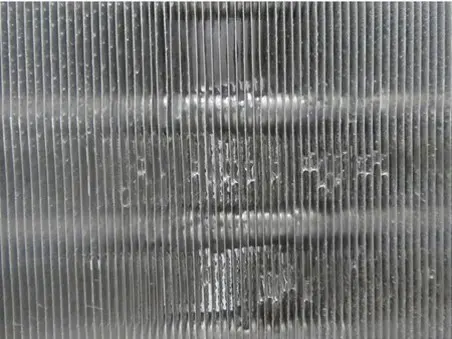

Moisture adheres to the fin surface as a result of condensation during cooling. Our highly hydrophilic aluminum fin stock improves the heat exchange rate of air conditioners and prevents water splashing.

Condensation on the heat exhanger

(2) Corrosion Resistance

When heat exchangers are used outdoors for long periods of time, its aluminum base corrodes with moisture and suspended solids. Corrosion-damaged aluminum severely lowers heat exchange performance. Our corrosion-resistant coating prevents corrosion of the aluminum base. We also provide products for harsher environments, such as places susceptible to salt damage.

(3) Press Formability

Forming a lubricant layer improves press formability and lowers wear on the press die.

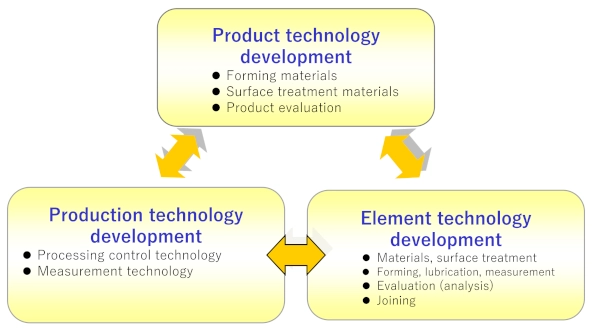

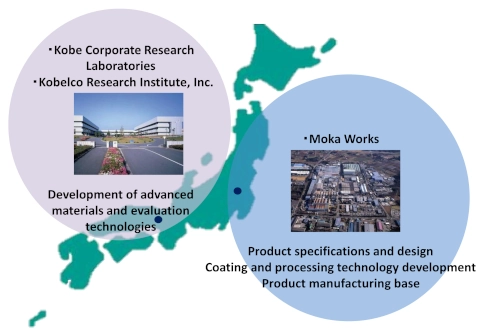

(4) Framework for Development

We are promoting Groupwide R&D efforts with the aim of developing products with high added value.

Lineup

Based on our multi-layer coating technology, we offer a range of pre-coated aluminum fin products with good hydrophilicity, corrosion resistance and press formability. In addition to the products shown in the table below, the lineup includes other products that are currently in mass production or under development. For any inquiries, please contact us using the Inqury button below.

| Use/Model | Indoor | Outdoor | Outdoor (Corrosion resistant) |

|---|---|---|---|

| KS176 | KS655 | KS101・KS128 | |

| Coating composition |

|

|

|

| Feature | Low odor and good fin formabiliy | High hydrophilicity maintained for a long time | High demand in areas susceptible to salt damage, with excellent corrosion resistance |

| Hydrophilicity | ◎ | ◎ | ○ |

| Odor inhibition | ◎ | - | - |

| Formability (lubricity) | ◎ | ○ | ◎ |

| Corrosion resistance | ○ | ○ | ◎ |

Pre-Coating Technology

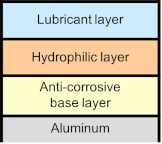

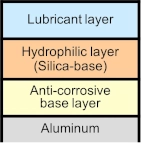

We have chemical conversion coating and multiple layer coating technologies, allowing us to meet our customers' multifunctional fin stock needs.

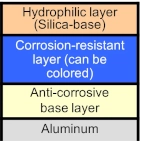

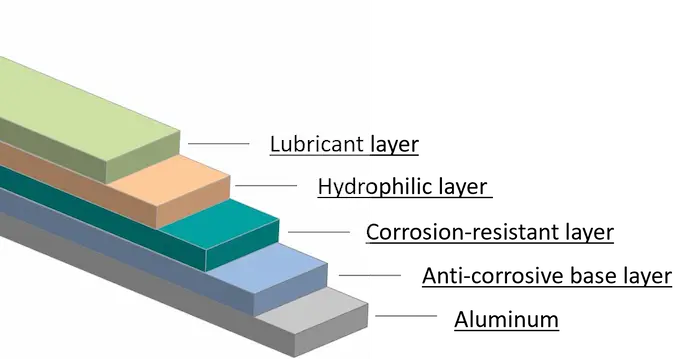

Technology to Enhance Functionality through Mutiple Layer Coating

Coatings as thin as a few microns are layered together to create materials with a wide range of performance properties, including hydrophilicity and corrosion resistance.

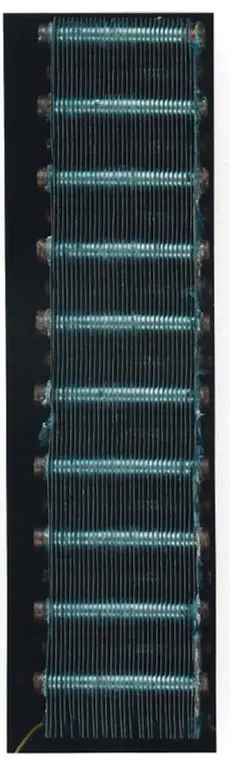

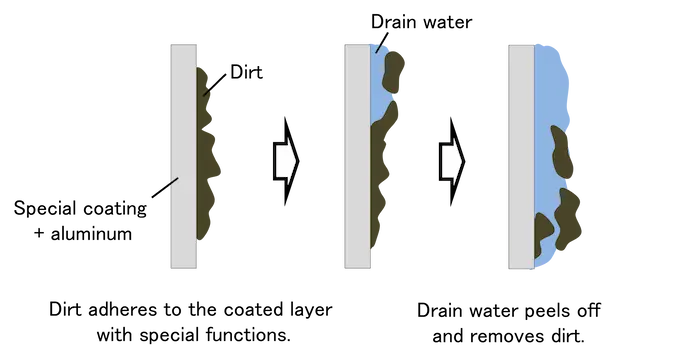

Application Example 1: Self-Cleaning Fin

The special coating washes away any dirt that adheres to it with condensed water, maintaining a clean coated surface.

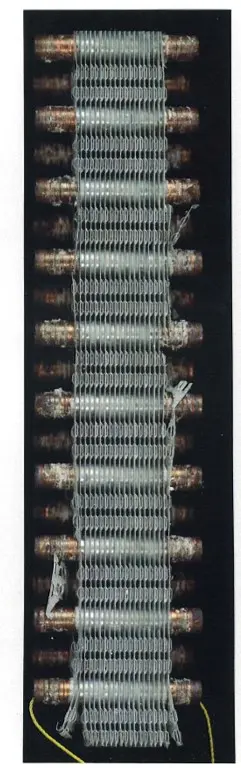

Application Example 2: Dust-Resistant Fin

The special coating prevents dust from adhering and maintains a clean coated surface.

- *Kanto loam (JIS test powder 1, 11 types) is used for dust components.

Aluminum Alloy

We offer a wide range of materials, including our unique highly formable materials with good press formability, allowing us to propose aluminum materials suited for a variety of fin material forming processes while meeting quality and tempering specifications.

- (1) 1J70

With high press formability, 1J70 can lower the costs by making the material thinner, while improving heat exchange performance and workability.

- (2) 1200

Ordinary aluminum with a purity of over 99.0%

Manufacturing dimensions (mm)

Thickness: 0.08-0.2

Width: up to 1600

- *Contact us for specifications that are not stated above.

Inquries and Sales of Pre-Coated Aluminum Fin Stock for Heat Exchangers

Our pre-coated aluminum fin stock is distributed through trading companies. The sales reach extends beyond Japan to China, South-East Asia, Europe, and other regions. For inquiries about our local trading companies and products, please contact us using the Inqury button below.

Contact Us

You can reach us by clicking the inquiry button.