High-Strength High Precision Aluminum Alloy Plate for Precision Machining ALJADE™-83

5083 boasts the highest strength among non-heat-treatable alloys, and is a 5000-series aluminum alloy with exceptional corrosion resistance properties and weldability.

Compared to JIS standards, ALJADE™-83 offers greatly improved flatness and thickness tolerance, as well as reduced residual stress.

ALJADE™-83 assists customers in reducing costs.

Features

- Improved manufacturing processes offer increased flatness.

- Our superior rolling technology offers approx. 1/4 the JIS standard accuracy for thickness.

- Our distinctive heat treatment process greatly reduces internal residual stress.

- The surface of each individual plate is carefully inspected to ensure a high quality surface on both sides.

Applications

- Structural materials

- Semiconductor manufacturing equipment

- LCD manufacturing equipment

- Solar panel manufacturing equipment

- Robots

- Medical equipment

- OA equipment

- Optical equipment

- Various molds & tools

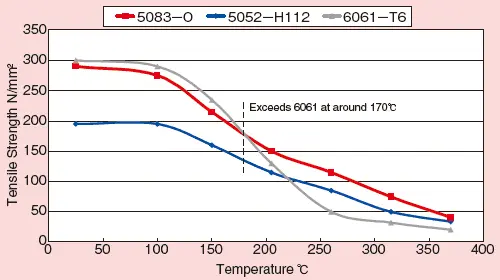

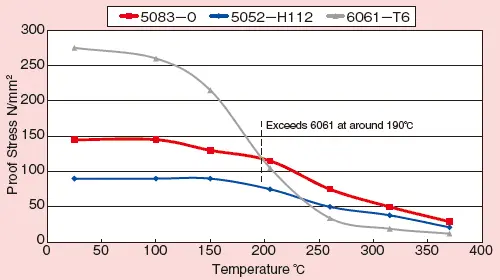

High-Temperature Characteristics

Quality / Refining / Composition

A5083P-O

(Unit: Wt/%)

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| ≤0.40 | ≤0.40 | ≤0.10 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | ≤0.25 | ≤0.15 | Remainder |

Thickness Accuracy

(Unit: mm)

| Thickness | 4 | 4<-≤5 | 5<-≤6 | 6<-≤12 | 12<-≤20 | 20<-≤30 | 30<-≤50 |

|---|---|---|---|---|---|---|---|

| ALJADE™-83 | ±0.08 | ±0.10 | ±0.12 | ±0.16 | ±0.30 | ±0.40 | ±0.50 |

(Unit: mm)

| Thickness | 4≤-≤5 | 5<-≤6 | 6<-≤8 | 8<-≤11 | 11<-≤16 |

|---|---|---|---|---|---|

| JIS Tolerance | ±0.35 | ±0.45 | ±0.50 | ±0.60 | ±0.70 |

Reference (Unit: mm)

| Thickness | 16<-≤22 | 22<-≤29 | 29<-≤35 | 35<-≤40 | 40<-≤50 |

|---|---|---|---|---|---|

| JIS Tolerance | ±0.80 | ±0.90 | ±1.0 | ±1.1 | ±1.3 |

Surface Flatness

- ALJADE™-83

Thickness 4-50 mm: 0.4 mm or less/M

Mechanical Properties (Typical Values)

| Thickness (mm) | Tensile strength (N/mm2) | Yield Strength (N/mm2) | Elongation (%) |

|---|---|---|---|

| 4-40 | 323 | 144 | 22 |

| 40-50 | 313 | 155 | 24 |

Product Size

| Thickness | Width × Length |

|---|---|

| 4-50 | 1,525×3,050 |

Catalog

- Japanese

- English

Contact Us

You can reach us by clicking the inquiry button.