In response to global warming, the Kobe Steel Group promotes rationalization and R&D geared toward reducing energy consumption throughout its operations, while decreasing greenhouse gas emissions.

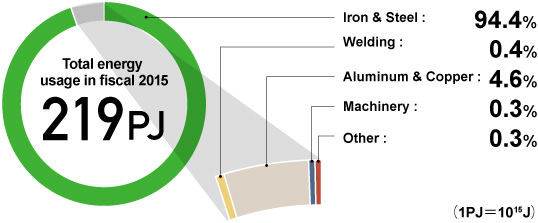

In fiscal 2015, the Kobe Steel Group used 219 PJ of energy (equivalent to 5.65 million kl of crude oil).

Of that total, approximately 94 percent was used in the Iron & Steel Business, and approximately 5 percent in Aluminum & Copper.

Energy Use by Business Unit (Includes Group Companies)

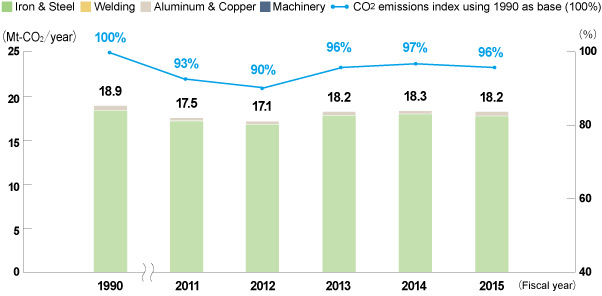

In fiscal 2015, total CO2 emissions for all of Kobe Steel's businesses were 18.2 Mt. Approximately 96 percent came from the Iron & Steel Business, and approximately 3 percent came from the Aluminum & Copper Business.

Emissions for fiscal 2015 decreased by 1 percent compared with the previous year and by 4 percent compared with fiscal 1990.

We engage in ongoing energy-saving initiatives, including improvements to productivity, optimization of equipment and reductions to energy loss.

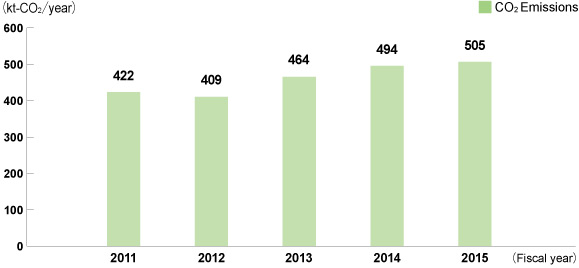

Kobe Steel Total

CO2 Emission Trends (Preliminary Calculations)

* Emission values for fiscal 1990 were calculated for the Aluminum & Copper Business using emissions from fiscal 1995, and for the Machinery Business using emissions from fiscal 1997, as a base.

* As emission factors from purchased power in fiscal 2015 have yet to be announced, results for fiscal 2014 were used.

* Emissions for past years have been recalculated due to revisions to power coefficients, etc.

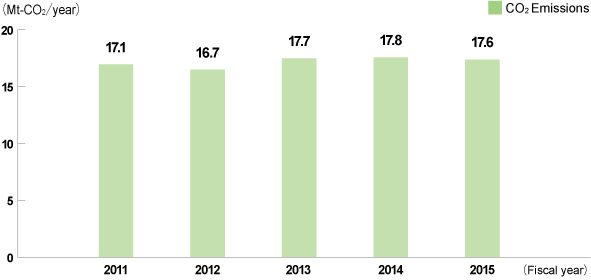

The Iron & Steel Business has been pursuing facility and operational improvements.

In fiscal 2015, we introduced inverters for fans at each location.

Emissions for fiscal 2015 decreased by approximately 1 percent compared with the previous year.

In the future, we will continue to implement energy conservation measures and reduce environmental impact, striving to achieve industry targets described in Nippon Keidanren's Commitment to a Low Carbon Society.

Iron & Steel Business (Kobe Steel)

CO2 Emission Trends (Preliminary Calculations)

* Preliminary calculations for Iron & Steel Business totals include coke production.

* As emission factors from purchased power in fiscal 2015 have yet to be announced, results for fiscal 2014 were used.

* Emissions for past years have been recalculated due to revisions to power coefficients, etc.

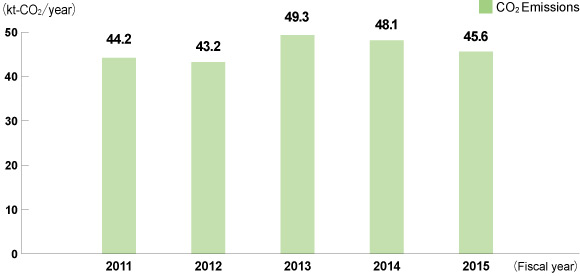

The Welding Business engages in ongoing energy-saving initiatives, including improvements to productivity, optimization of equipment and reductions to energy loss.

In fiscal 2015 we introduced LED lighting, installed inverters at plants, and carried out other similar, systematic initiatives at all locations.

Emissions for fiscal 2015 decreased by approximately 5 percent compared with the previous year.

In future years. we will continue to pursue additional energy-saving measures and further reduce environmental impact.

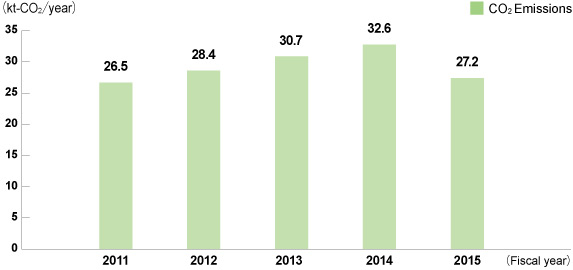

Welding Business (Kobe Steel)

CO2 Emission Trends (Preliminary Calculations)

* Emissions for past years have been recalculated due to revisions to power coefficients, etc.

The Aluminum & Copper Business has been switching from oil-based fuels to natural gas, as well as pursuing equipment intensification and efficiency.

In fiscal 2015, we implemented measures at different locations, including introduction of steam compressors, updates to waste heat recovery equipment and improved insulation for heat treatment furnaces.

Emissions for fiscal 2015 increased by 2 percent compared with the previous year.

In the future, we will continue to implement energy conservation measures and reduce environmental impact, striving to achieve industry targets described in Nippon Keidanren's Commitment to a Low Carbon Society.

Aluminum & Copper Business (Kobe Steel)

CO2 Emission Trends (Preliminary Calculations)

* Emissions for past years have been recalculated due to revisions to power coefficients, etc.

As demand for products such as energy-saving compressors, heat pumps and heavy-wall pressure vessels for the oil refining sector increases, the Machinery Business is also striving to increase energy efficiency through optimization of equipment and improvements to productivity.

Emissions in fiscal 2015 decreased by 17 percent compared to the previous year.

In the future, we will continue to implement energy conservation measures and reduce environmental impact, striving to achieve industry targets described in Nippon Keidanren's Commitment to a Low Carbon Society.

Machinery Business (Kobe Steel)

CO2 Emission Trends (Preliminary Calculations)

* Emissions for past years have been recalculated due to revisions to power coefficients, etc.

We pursue energy-saving initiatives at our manufacturing locations to combat global warming and reduce energy costs.

The MONODZUKURI (Production System Innovation) Planning & Promotion Department, as a part of manufacturing technology exchange activities at manufacturing locations, launched an energy-saving technology subcommittee in fiscal 2012 to support energy-saving activities. In fiscal 2015 the MONODZUKURI Planning & Promotion Department undertook further energy-saving initiatives and activities to raise the level of on-site engineers through expert-led support for energy-saving technologies at locations, energy conservation exchange meetings (to share examples of energy-saving activities and information on energy-saving technologies, etc.), and training in energy conservation.

As an energy-saving technology support activity, heat diagnosis, based on more detailed measurements than before, were carried out on a variety of large and small heating equipment installed at various facilities. A range of new approaches were proposed for further energy savings, with technological guidance provided during implementation.

As of the end of fiscal 2015, proposals to reduce energy consumption by more than 10 percent per piece of equipment—a CO2 equivalent of 4,400 t/yr—were completed for six pieces of equipment at six locations, and are currently being implemented on-site.

Similar initiatives are being rolled out for heating equipment at four other sites, with the medium-term plan also calling for expansion to Group companies.

| Business unit | Production site | Equipment | Status |

|---|---|---|---|

| Iron & Steel | Kobe Works | Continuous heating furnace for steel sheet | Finished |

| Takasago Works | Heating furnace for forging | Finished | |

| Heating furnace for forging | In progress | ||

| Welding | Fukuchiyama Plant | Annealing furnace | Finished |

| Ibaraki Plant | Drying furnace | In progress | |

| Aluminum & Copper | Moka Plant | Soaking furnace | Finished |

| Aluminum melting furnace | In progress | ||

| Chofu Works | Continuous heating furnace for copper sheet | Finished | |

| Billet heater | In progress | ||

| Daian Plant | Melting furnace | Finished |

From raw materials procurement to product delivery, the Kobe Steel Group aims to conserve energy through the use of optimized and speedy transportation. Ongoing improvements include expanding modal shifts from the use of trucks to the use of rail and ships; increasing loading efficiency; improving transportation efficiency through larger vehicles; and expanding use of roundtrip shipping.

We have also been working to improve fuel efficiency, such as through introduction of cutting-edge transport ships for steel products and lighter weight shipping vehicles.

Individual Kobe Steel Group companies also strive to reduce energy during manufacturing processes and distribution. In addition to the initiatives mentioned below, Group companies also implement a wide array of daily measures to conserve energy, such as turning off lights and regulating air conditioning.

| Company name | Location | Examples of major initiatives |

|---|---|---|

| Shinko Wire Company, Ltd. | Kakogawa, Hyogo Prefecture | Switched to LED lighting at production facilities Switched to inverters for wound motors |

| Ceratechno Co., Ltd. | Bizen, Okayama Prefecture | Switched to inverter-type 150tf press (main unit) Introduced ultra energy-saving hydraulic unit for tube press Reduced leaks from air pipes |

| Nippon Koshuha Steel Co., Ltd. | Imizu, Toyama Prefecture | Installed high radiant material at Nos. LS-2, 3 and 5 radiant tubes |

| Japan Aeroforge, Ltd. | Kurashiki, Okayama Prefecture | Consolidated hot forging lots (for greater mass production) |

| Hanshin Yosetsu Kizai Co., Ltd. | Okayama, Okayama Prefecture | Switched to 45 kW inverter-type RD dust collector fan and changed number of revolutions Switched to LED ceiling lighting |

| Shinko Aluminum Wire Co., Ltd. | Sakai, Osaka Prefecture | Switched to inverter-type 75 kW compressor Changed inverter circuit at heating furnace for rolling mill |

| Shinko Engineering Co., Ltd. | Ogaki, Gifu Prefecture | Switched from mercury lamps to LED |

| Kobelco Eco-Solutions Co., Ltd. | Kako-gun, Hyogo Prefecture | Improved combustion at combustion furnaces (Nos. 2, 3, 5) |

| Shinko Kohan Kako, Ltd. | Ichikawa, Chiba Prefecture | Installed inverter chiller for laser cutter |

| PRO-TEC Coating Company | Ohio, USA | Updated to energy-saving, motion detector lighting inside the facility and turned off power for non-vital areas when plant is not in operation |

| Kobe Wire Products (Foshan) Co., Ltd. | Foshan, Guangdong Province, China | Used battery-powered forklifts and promoted activities to reduce LPG consumption per unit (reducing amount used through recovery of waste heat) |

| Kobelco Welding of Europe B.V. | Limburg, Netherlands | Introduced heat recovery equipment to reduce power consumption Introduced new energy-saving air conditioning system |

| Kobe Precision Technology Sdn. Bhd. | Penang, Malaysia | Updated some lighting to LED Updated to high-efficiency air conditioning cooling tower and introduced timers to reduce unnecessary lighting |

| Kobelco Compressors Manufacturing Indiana, Inc. | Indiana, USA | Used in-plant heat recovery process during winter Optimized performance for commissioning equipment |

| Kobelco Stewart Bolling, Inc. | Ohio, USA | Introduced circulating coolant system for air compressors Introduced two high-efficiency boilers for office air conditioning |