Home > Products > Ultra High Pressure Equipment > High Temperature and High Pressure Equipment > Cold Isostatic Pressing (CIP) Equipment > Rubber Isostatic Pressing (RIP) Equipment

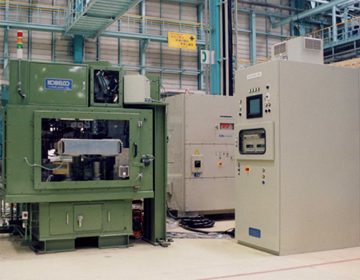

Rubber Isostatic Pressing (RIP) Equipment

Rubber Isostatic Pressing (RIP) Equipment

What is the RIP Method?

Rubber Isostatic Pressing (RIP) is a method to mold powder filled into the rubber mold by generating isostatic pressure by presssing the rubber mold set in a metal mold with a punch. This equipment is simpler, safer and more secure compared with CIP due to no use of a liquid pressure medium. According to data, the compression properties of RIP are almost equal to CIP.

Features

Fixing of the periphery of the rubber mold restrains its deformation, which assures products with high dimensional accuracy.

Fixing of the periphery of the rubber mold restrains its deformation, which assures products with high dimensional accuracy.  Isostatic pressure forming makes the product density uniform.

Isostatic pressure forming makes the product density uniform.  Simple structure of the equipment shortens the cycle time and improves productivity. It can also save the cost and the replacing time of metals molds necessary for the conventional presses.

Simple structure of the equipment shortens the cycle time and improves productivity. It can also save the cost and the replacing time of metals molds necessary for the conventional presses.  The attached powder charging unit using the air tapping (AT) method provides uniform and high-density powder charging in a short time even for low fluidity powder.

The attached powder charging unit using the air tapping (AT) method provides uniform and high-density powder charging in a short time even for low fluidity powder.  Complex-shaped products, for which CIP has difficulties in mass-producing, are available in a short cycle.

Complex-shaped products, for which CIP has difficulties in mass-producing, are available in a short cycle.  For magnetic powder, orientation of grain direction before compressing makes the magnets more powerful.

For magnetic powder, orientation of grain direction before compressing makes the magnets more powerful.

Main Performances

| Pressing Force | Standard: 785 kN (Approximately 100 MPa in terms of Internal Pressure) * Other equipment is available upon your request. |

|---|---|

| Cycle Time | Standard: 30 sec. * The cycle time and dimensional accuracy depend on products, powder properties, and the shape and size of the molded body. |

Medium-and Large-Scale HIP Equipment

Medium-and Large-Scale HIP Equipment Standard Small-Scale HIP Equipment

Standard Small-Scale HIP Equipment Dr. Series

Dr. Series Sintering HIP Equipment

Sintering HIP Equipment Ultra High Temperature / Ultra High Pressure HIP Equipment

Ultra High Temperature / Ultra High Pressure HIP Equipment Other HIP Equipment

Other HIP Equipment Metal Capsule Manufacturing Equipment

Metal Capsule Manufacturing Equipment Compound Semiconductor Single Crystal Manufacturing Equipment

Compound Semiconductor Single Crystal Manufacturing Equipment

![]()