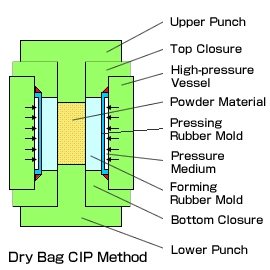

Dry Bag CIP Equipment

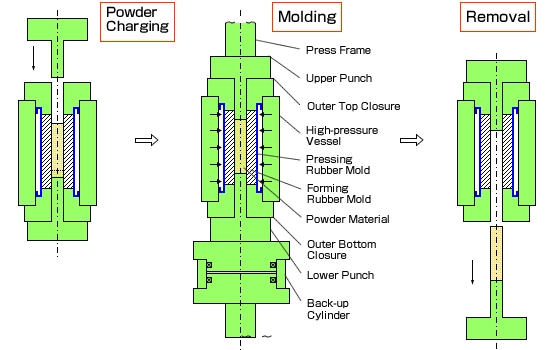

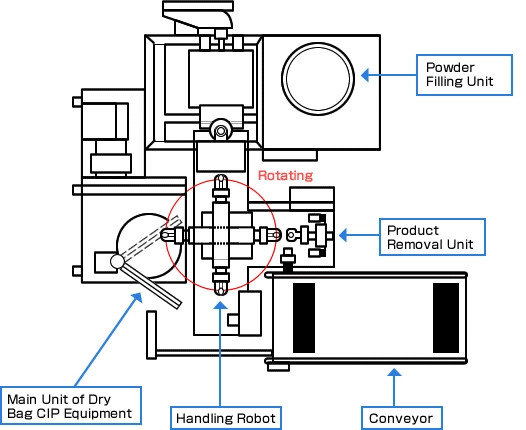

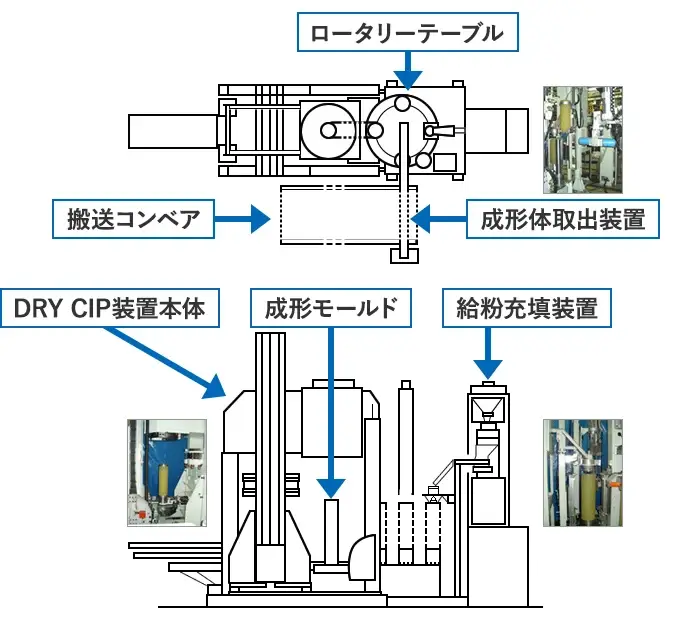

Dry Bag CIP is a method to mold powder (substances) filled in a forming rubber mold by transmitting pressure through a pressing rubber mold in the high-pressure vessel. This method is suitable for mass production of simple and limited variety of products with its labor-saving automatic operation. It is widely-accepted in the carbide, ceramics and many other industries.

Features

- Perfect solution based on powder properties and product specifications.

- High productivity and reliability by automated technologies based on our past experiences.

- Enhanced product precision and yield by refined rubber mold technologies.

- Quick-change system to replace a forming rubber mold very easily.

- Prevention of cracks on products by back-up cylinders.

Applications

Dry Bag CIP Equipment (Example 1)

| Inner Diameter of Rubber Mold | Φ45mm X 300mmL |

|---|---|

| Maximum Pressure | 196MPa(2000kgf/cm2) |

| In-line System | Circumferential Pressurization |

Dry Bag CIP Equipment (Example 2)

| Inner Diameter of Rubber Mold | Φ45mm X 600mmL |

|---|---|

| Maximum Pressure | 147MPa(1500kgf/cm2) |

| Offline System | Circumferential Pressurization |

Dry Bag CIP Equipment (Example 3)

| Inner Diameter of Rubber Mold | Φ160mm X 550mmL |

|---|---|

| Maximum Pressure | 343MPa(3500kgf/cm2) |

| Offline System | Circumferential Pressurization |

Contact Us

You can reach us by clicking the inquiry button.