Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2011 > Disaster Prevention Activities

Disaster Prevention Activities

Disaster Prevention Activities

| Preparing for natural disasters and preventing accidents, groupwide organization further reinforces disaster prevention capabilities. |

The Kobe Steel Group continues to implement groupwide protective measures for its facilities and prepare for natural disasters through such means as holding groupwide disaster prevention meetings, establishing disaster response systems, and holding training exercises. These measures are actively pursued to prevent accidents from occurring and to minimize damage if a disaster does strike.

We will continue to raise every employee's awareness of the importance of disaster prevention while further pursuing disaster prevention activities on a groupwide level.

FY2010 Companywide Disaster Prevention Management Policy

| Basic Policy: Complying with the law, eliminating accidents, and reinforcing preparedness in the event of a natural disaster We recognize that compliance with disaster prevention laws and regulations is an essential part of our business activities. We make every effort to eliminate accidents and reinforce preparedness in the event of a natural disaster. Respecting human life, we are committed to ensuring the continuation of our business activities and providing reassurance for the local community. |

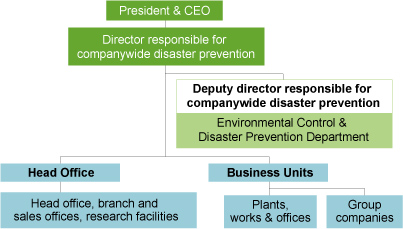

Companywide Disaster Prevention Management Structure

Companywide Disaster Prevention Management Structure

Disaster Management

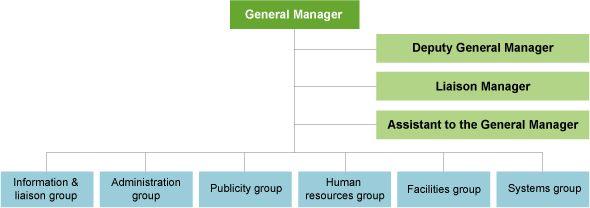

Organization Chart for Disaster Management Headquarters

| * The General Manager of the Disaster Management Headquarters is the President of Kobe Steel. The President appoints the Deputy General Manager of the Disaster Management Headquarters. |

Group Disaster Prevention Meeting

We organize Kobe Steel Group Disaster Prevention Meetings every year in an effort to share information and reinforce disaster prevention initiatives. A total of 119 employees from 58 Group companies took part in the fiscal 2010 meeting, which featured updates on the latest revisions to laws and regulations, reports on initiatives at individual sites and a special lecture by InterRisk Research Institute & Consulting, Inc., underlining the importance of ongoing disaster prevention activities.

Group Disaster Prevention Meeting in November 2010

Onsite Disaster Prevention Inspections

We conduct onsite disaster prevention inspections at our facilities in order to verify levels of compliance with disaster prevention laws and minimize risks that could potentially lead to accidents. Inspections during fiscal 2010 found no serious legal violations.

We intend to roll out similar activities to Group companies in the future, in order to reinforce our groupwide disaster prevention management system.

Disaster prevention inspection at Daian Plant

Disaster Prevention Measures at Plants, Works and Offices

Despite making every effort to prevent accidents, we were once again unable to completely eliminate fires and other accidents during fiscal 2010.

We have investigated the causes of all accidents however, and are taking appropriate action.

In the future, we intend to step up efforts to prevent recurring accidents, share information on accidents that have occurred and roll out disaster prevention activities aimed at preventing similar accidents, in an effort to eliminate accidents throughout the Kobe Steel Group.

Main Incidents in Fiscal 2010

| Date and Location | Incident |

| October 2010 Takasago Works |

Oil leaked from a large press during forging, causing high temperature forged material to catch fire. |

| December 2010 Kobe Works |

Desulfurization chemicals from a hot metal pretreatment furnace, used to adjust the chemical composition of pig iron, leaked out from a storage tank and reacted with water, generating heat that caused cables and other components to burn. |

| March 2011 Kakogawa Works |

Molten metal coming out of an electric arc furnace overflowed from the guttering, causing nearby equipment to burn. |

Accidents and Incidents at Manufacturing Locations in Fiscal 2010

| Location | Number of Incidents |

| Kobe Works | 1 |

| Kakogawa Works | 6 |

| Fujisawa Works | 0 |

| Ibaraki Plant | 0 |

| Saijo Plant | 0 |

| Moka Plant | 0 |

| Location | Number of Incidents |

| Chofu Works | 0 |

| Daian Plant | 0 |

| Harima Plant | 0 |

| Kobe Corporate Research Laboratories | 0 |

| Takasago Works | 3 |

Disaster Prevention Activities at Plants, Works and Offices

We conduct regular emergency drills at each of the Kobe Steel Group's plants, works and offices. As part of an emergency drill on January 17, 2011 at the Takasago Works , 110 employees took part in a simulation-based training exercise in which a tent was filled with harmless smoke in order to demonstrate how overwhelming smoke can be. Participants commented that the exercise reaffirmed the importance of preventive measures in the event of a fire or other such accident.

Smoke simulation exercise (Takasago Works)

Kobelco 1/17 Walk

On January 15, 2011, we organized the 5th Kobelco 1/17 Walk in the area around our Kobe Head Office. The aim of this event is to confirm people's safety in the event of a breakdown in public transport following an earthquake or other major disaster. Around 170 people took part.

This exercise is designed to prepare people to walk to and from work in such an event, and to remind them of the lessons learned from the Great Hanshin-Awaji Earthquake. We consider this to be an extremely important initiative, especially in light of experiences following the Great East Japan Earthquake. We will continue to organize walks in the future.

Participants arrive at the destination of the Kobelco 1/17 Walk. (January 2011)

Koji Fujii, Officer

Director responsible for companywide disaster prevention

|

Here at the Kobe Steel Group, we have long since implemented a range of measures, both tangible and intangible, in preparation for an earthquake or other natural disaster. Fortunately, this meant that none of our employees were harmed during the recent earthquake. In fact, we were able to respond to the earthquake relatively smoothly, including verifying people's safety and restarting operations at affected offices and facilities. We will make the most of these experiences to ensure that we are even better prepared in the event of any disasters in the future. |

|

Response to the Great East Japan Earthquake

We have long since implemented a range of measures in the event of an earthquake or other natural disaster here at Kobe Steel.

As a result, at our Moka Plant we were able to quickly restore operations on March 25 following the Tohoku earthquake, which registered an intensity of 6.

Based on our recent experiences, we will continue to reinforce preparedness in the event of a natural disaster in the future.

Evaluation of Earthquake Preparedness and Our Response to the Great East Japan Earthquake

| Category | Earthquake Preparedness | Response Following Earthquake | Evaluation | Future Initiatives |

| Measures to Make Buildings Resistant to Earthquakes | Establishing earthquake-proofing guidelines (Buildings should sustain no damage resulting in loss of function, even in an intensity 6 earthquake.); diagnosing earthquake resistance of factory buildings, offices, company housing and other key facilities; and carrying out building reinforcement work. | Although some fixtures and fittings came away from the wall and some minor cracks were reported at offices, company housing and other facilities at the Moka Plant, there was no serious damage to any buildings and no employees or other persons were injured. | We will implement all necessary measures in line with revisions to emergency plans set out by the Central Disaster Prevention Council and other national and local government bodies. | |

| IT-related Earthquake Measures | Earthquake-proofing buildings housing computers, taking steps to protect computers themselves and implementing measures such as backing up systems. | As we had previous installed seismic isolation flooring at the Moka Plant, there was no damage to either computers or data. | o | We will continue to implement IT-related earthquake measures and back up systems throughout the Kobe Steel Group. |

| Emergency Communication | Installing satellite telephone or wireless systems at plants and works, head office and branch offices. Introducing telephone priority systems in the event of a disaster. | Satellite telephones acted as an extremely effective means of communication between the Moka Plant and Tokyo Head Office. | o | We will monitor technical development in the communications sector and install the latest means of communication if deemed viable. |

| Installing Earthquake Early Warning Systems | Installing earthquake early warning systems at plants and works, head offices, branch offices and sales offices in order to minimize human and physical damage. | Although there are still some outstanding issues in terms of predictive accuracy, all of our employees were able to prepare themselves for an earthquake when the earthquake early warning was sounded. | We will explore more effective ways of issuing earthquake early warnings. | |

| Disaster Management Headquarters | Establishing a companywide Disaster Management Headquarters at Tokyo Head Office in the event of a large-scale earthquake or other natural disaster or emergency (Kobe Head Office if Tokyo Head Office has been damaged and is out of commission). Producing manuals detailing relief and restoration procedures. | We established a headquarters at Tokyo Head Office to verify people's safety and provide assistance for affected locations. We also provided support to get operations up and running again as quickly as possible (coordinating and shipping relief supplies, etc.). | o | We will revise manuals and continue to implement educational and training activities to facilitate response measures wherever possible. |