Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2012 > Materials

Materials

Materials

Contributing to the Environment through Products, Technologies and Services

At the Kobe Steel Group, we have established a wide range of comprehensive capabilities over the course of many years as a materials producer, in areas such as cutting-edge technology, manufacturing, processing and product development. We make the most of those capabilities to provide original "Only One" products – including high-grade steel products, titanium and aluminum components – that are environmentally friendly.

Symbols indicate the areas in which products are used, so that customers can see how they relate to their lives.

Titanium sheet products for heat exchangers

Titanium sheet products for heat exchangers

![]()

We have developed a precoated titanium sheet and high heat-transfer titanium sheet for use in plate heat exchangers (PHE), one of the main areas in which commercially pure titanium sheet is used. This is the first time anywhere in the world that commercially pure titanium sheets have been successfully developed into commercial products.

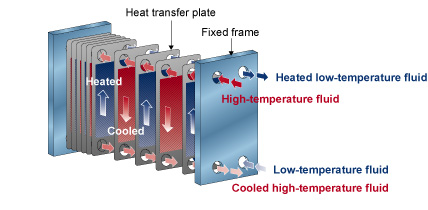

Structure of a plate heat exchanger (PHE)

Structure of a plate heat exchanger (PHE)

(1) Precoated titanium sheet

Our titanium sheet with an acrylic resin precoat provides nearly the same level of formability and productivity as pressing the metal using a lubricating film. As no lubricating film is used, the new sheet eliminates the cost of removing the film and disposing the film.

(2) High heat-transfer titanium plates

Adding minute convex-shaped bumps to the surface of titanium sheet increases heat transfer efficiency by more than 10% if used in an evaporator, or by 5% if used in a condenser or fluid-to-fluid heat exchanger. This increase in efficiency helps save energy and conserve resources by reducing the number of heat transfer plates, fluid flow rate and pump usage, as well as streamlining heat exchangers and cutting costs.

World's first 1180Mpa high strength steel sheet to be used in automobiles

World's first 1180Mpa high strength steel sheet to be used in automobiles

![]()

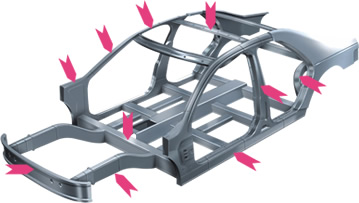

Automobiles need to be made lighter and stronger to improve fuel efficiency and comply with increasingly strict crash safety regulations. Striking a balance between these two qualities requires high tensile strength materials that are strong but easy to form.

At Kobe Steel, we have developed TBF* 1180MPa high strength steel with improved elongation, which is crucial to formability, and outstanding resistance to delayed fracture. Following development of an innovative spot welding method by Nissan Motor Co. Ltd., this new material will be used in structural members for the body of a new car model due to go on sale in 2013. This is the first time anywhere in the world that 1180MPa high strength steel will be used for major structural components in a car.

* TBF (TRIP-aided bainitic ferrite) high strength steel

TBF high tensile strength steel sheet combines strength with formability. This steel is noted for its fine retained austenite, which improves ductility, and a matrix phase consisting of bainitic ferrite for high strength. It was developed under joint research and development with Professor Koichi Sugimoto of Shinshu University based on a TBF steel developed by Professor Sugimoto.

Uses for high strength steel from 2015 and beyond envisioned by Kobe Steel

Uses for high strength steel from 2015 and beyond envisioned by Kobe Steel

Cleansing contaminated soil and purifying groundwater with ECOMEL® environmental iron powders

Cleansing contaminated soil and purifying groundwater with ECOMEL® environmental iron powders

![]()

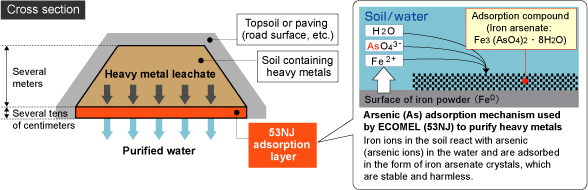

In an effort to tackle the increasingly serious issue of soil and groundwater contamination and contribute to society in a new way, we have developed the ECOMEL series of environmental iron powders.

As well as ECOMEL 58NJ-1, which breaks down manmade contaminants consisting of volatile organic compounds (VOC), in 2010 we added ECOMEL 53NJ, which adsorbs soil contaminants such as arsenic and other naturally occurring heavy metals. Both of these products have proved effective in real situations.

ECOMEL 53NJ, for heavy metal adsorption, has been shown to adsorb ten times as much arsenic as other commercially available steel powders and is also able to adsorb substances such as selenium, chromium, lead and cadmium. As such, it is ideally suited for combating naturally occurring soil contamination, in cases where the soil is likely to be contaminated with multiple heavy metals.

Using ECOMEL prevents over-reliance on excavation and removal, as specified in the revised Soil Contamination Countermeasures Act, and has the potential to reduce the cost of dealing with contaminated soil.

Example of heavy metal adsorption using ECOMEL (adsorption layer method)

Example of heavy metal adsorption using ECOMEL (adsorption layer method)

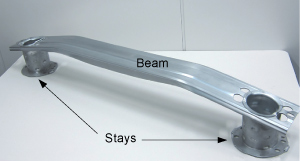

Aluminum bumper system used in Lexus GS

Aluminum bumper system used in Lexus GS

![]()

formed pierced stays

Aluminum automotive materials developed by Kobe Steel have been used in Toyota Motor's Lexus GS. We were the first in the world to develop and mass produce pierced aluminum stays and an aluminum bumper assembled in one unit using an electromagnetic pipe expanding process. By successfully making vehicles lighter and reducing the number of components, this bumper system makes it possible to streamline the manufacturing process and thereby reduce costs, making it a more environmentally friendly option.

The development of this product was recognized at the Toyota Global Suppliers Convention in February, when we received an award for technical development.

Kobelco & Materials Copper Tube, Ltd.

Kobelco & Materials Copper Tube, Ltd.

Minimizing calcium carbonate deposits with new copper tubes for EcoCute heat pump water heaters

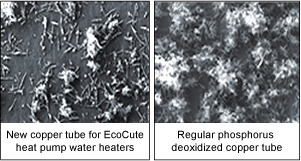

![]()

a highly concentrated calcium solution

In conjunction with Kobelco & Materials Copper Tube, Ltd., we have developed copper alloy tubes resistant to calcium carbonate for use in EcoCute heat pump water heaters.

The new tubes contain additives that minimize calcium carbonate scaling, including phosphorus and tin. By modifying the annealing process, we have designed tubes so that the concentration of phosphorus and tin increases closer to the inside of the tube.

In accelerated tests using a highly concentrated calcium solution, deposits were reduced to less than half compared to regular phosphorus deoxidized copper tubes. This will help resolve problems such as blockages and reduced heat exchange performance. It will also enable smaller diameter tubes to be developed, thus reducing the amount of copper used.