Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2012 > Disaster Prevention Activities

Disaster Prevention Activities

Disaster Prevention Activities

The Kobe Steel Group continues to implement groupwide protective measures for its facilities and prepare for natural disasters through such means as holding groupwide disaster prevention meetings, establishing disaster managementsystems, and holding training exercises. These measures are actively pursued to prevent accidents from occurring and to minimize damage if a disaster does strike.

We will continue to raise every employee's awareness of the importance of disaster prevention while further pursuing disaster prevention activities on a groupwide level.

FY2011 Companywide Disaster Prevention Management Policy

![]()

Basic Policy:

Complying with the law, eliminating plant accidents, and reinforcing preparedness in the event of a natural disaster

We ensure compliance with all disaster prevention legislation, strive to eliminate accidents in the workplace and make sure that we are fully prepared in the event of natural disaster. We have the utmost respect for human life and are committed to continuing our business activities and providing reassurance for the local community.

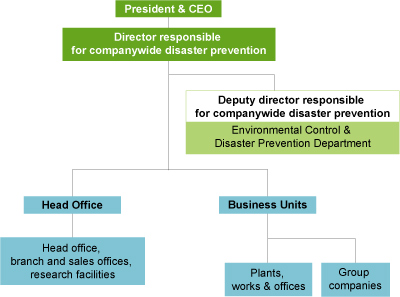

Companywide Disaster Prevention Management Structure

![]()

We implement disaster prevention management activities throughout the Kobe Steel Group, under the supervision of the President and the director responsible for companywide disaster prevention.

Companywide Disaster Prevention Management Structure

Companywide Disaster Prevention Management Structure

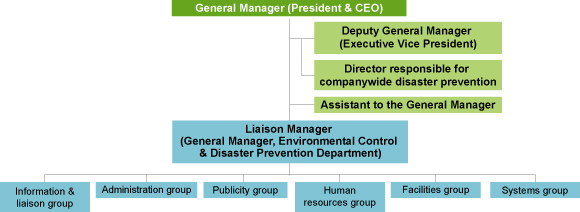

Disaster Management

![]()

In the event of a large-scale earthquake, or other natural disaster or accident, we will set up a Disaster Management Headquarters at our Tokyo Head Office (or Kobe Head Office) to coordinate relief efforts and restoration activities.

When the Great East Japan Earthquake struck, we established a headquarters at our Tokyo Head Office to verify people’s safety and provide assistance for affected locations. We also provided support to get operations up and running again as quickly as possible, including coordinating and shipping relief supplies.

As well as revising manuals, we intend to implement ongoing educational and training activities in the future to ensure that we can respond to any disaster as smoothly as possible.

Disaster Management Headquarters

Disaster Management Headquarters

Group Disaster Prevention Meeting

![]()

We organize Kobe Steel Group Disaster Prevention Meetings every year in effort to share information and reinforce disaster prevention initiatives. A total of 80 employees from 41 group companies took part in our fiscal 2011 meeting, which featured updates on the latest revisions to laws and regulations, reports on initiatives at individual sites, and presentations from sites damaged by the Great East Japan Earthquake, underlining the importance of ongoing disaster prevention activities on a day-to-day basis.

Onsite Disaster Prevention Inspections

![]()

Eco-Solutions (Harima Plant)

We conduct onsite disaster prevention inspections at our facilities in order to verify levels of compliance with disaster prevention legislation and minimize risks that could potentially lead to accidents. Having introduced inspections at group companies during fiscal 2011, we found no serious legal violations. We will continue to reinforce disaster prevention management systems throughout the Kobe Steel Group in the future.

Disaster Prevention Measures at Plants, Works and Offices

![]()

Despite making every effort to prevent accidents, we were once again unable to completely eliminate fires and other accidents during fiscal 2011. We have investigated the causes of all accidents however, and are taking appropriate action.

In the future, we intend to step up efforts to prevent recurring accidents, share information on accidents that have occurred and roll out disaster prevention activities aimed at preventing similar accidents, in an effort to eliminate accidents throughout the Kobe Steel Group.

Main Incidents in Fiscal 2011

Main Incidents in Fiscal 2011

| Date and Location | Incident |

|---|---|

|

May 2011 Kakogawa Works |

The cover on a coke oven gas booster fan became dislodged at the cold strip mill’s continuous annealing line. Gas leaked out due to a worn seal and ignited. |

|

January 2012 Kobe Works |

Hot slag sprayed out from a slag processing facility, setting fire to product packaging in an adjoining warehouse. |

|

January 2012 Kakogawa Works |

A fire broke out due to friction between a conveyor belt and rollers in the raw material yard. |

Accidents and Incidents at Manufacturing Locations in Fiscal 2011

Accidents and Incidents at Manufacturing Locations in Fiscal 2011

| Location | Number of Incidents | Location | Number of Incidents |

|---|---|---|---|

| Kobe Works | 1 | Moka Plant | 0 |

| Kakogawa Works | 4 | Chofu Works | 0 |

| Fujisawa Plant* | 0 | Daian Plant | 0 |

| Ibaraki Plant | 0 | Harima Plant | 0 |

| Saijo Plant | 0 | Kobe Corporate Research Laboratories | 0 |

| Fukuchiyama Plant | 0 | Takasago Works | 0 |

* Name changed to Fujisawa Plant as of April 1, 2012. Includes the Production Center, Technical Center and group company facilities.

Disaster Prevention Activities at Plants, Works and Offices

![]()

simulation vehicle (Fujisawa Plant)

We conduct regular emergency drills at each of the Kobe Steel Group's plants, works and offices.

On March 12, 2012, we conducted an emergency drill at our Fujisawa Plant, based on a scenario involving an earthquake directly underneath Tokyo. As well as simulating evacuation, safety checks and notification procedures when the earthquake early warning system was sounded, the drill enabled employees to verify evacuation locations on higher ground, in the event of a tsunami, and experience a magnitude-7 earthquake for themselves in an earthquake simulation vehicle.

We also conducted an emergency drill at night, which involved evacuating the premises using only emergency lighting, simulating a power failure as a result of an earthquake.

Kobelco 1/17 Walk

![]()

1/17 Walk. (January 2012)

On January 21, 2012, we organized the 6th Kobelco 1/17 Walk in the area around our Kobe Head Office. The aim of this event is to confirm routes to work in the event of a breakdown in public transport following an earthquake or other major disaster. Around 180 people took part.

Using maps distributed beforehand, participants actually walked their respective routes, checking potential hazards and facilities that would be useful in an emergency, such as convenience stores and toilets, along the way.

As this is an important exercise in terms of being prepared for an earthquake or other disaster, we will continue to organize walks in the future so that we can all learn from our experiences following the Great Hanshin-Awaji Earthquake.

Continuing with activities aimed at enhancing the Kobe Steel Group’s disaster prevention capabilities

Officer

Director responsible for companywide

disaster prevention

In accordance with the Kobe Steel Group’s Companywide Disaster Prevention Management Policy, we are committed to complying with disaster prevention legislation, enhancing management systems to eliminate accidents in the workplace and implementing disaster prevention management activities to ensure that we are prepared in the event of a natural disaster.

In fiscal 2011, we started onsite disaster prevention inspections at group companies, in addition to Kobe Steel facilities. Based on our experiences following the Great East Japan Earthquake, we have taken steps to ensure that we are prepared in the event of a natural disaster.

We are determined to keep on implementing individual activities such as these in the future to enhance our disaster prevention capabilities and make the Kobe Steel Group more resilient to natural disasters.