Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2013 > The KOBELCO Value Chain Reducing the Burden on the Environment

The KOBELCO Value Chain Reducing the Burden on the Environment

The KOBELCO Value Chain Reducing the Burden on the Environment

Reducing the Burden on the Environment

From the procurement of raw materials to customer use, the Kobe Steel Group engages in ongoing efforts to reduce the environmental impact at all stages. The Kobe Steel Group value chain delivers high-quality products to customers with the added value of reduced environmental impact. Below we introduce the Iron & Steel Business as an example of this process.

Procurement of Raw Materials

Procurement of Raw Materials

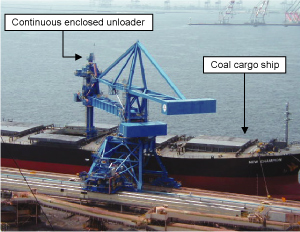

One of Japan's largest continuous enclosed

unloaders in operation at the Kobe Works

Efforts to reduce the environmental impact begin at the procurement phase, with initiatives such as the efficient operation of cargo ships for iron ore and coal.

Example of Initiative

![]()

More Efficient Transportation of Raw Materials through Ocean Shipment

![]()

Iron ore and coal, the raw materials used to create steel, are mined overseas and then shipped to the steelworks using cargo ships. Kobe Steel endeavors to further reduce the environmental impact through efficient operation of these ships.

Aiming for maximum efficiency when transporting raw materials, Kobe Steel considers a variety of issues, such as steelworks production schedules and demand, the progress of work at loading ports, and weather conditions along shipping routes, so as to reduce demurrage (waiting times) and improve fuel efficiency.

Manufacturing

Manufacturing

Steel slag

The new steel plate heat

treatment furnace now in

operation

In order to reduce the environmental impact of manufacturing processes at the steelworks, energy consumption is reduced via optimization of equipment and machinery, management of waste heat, and other such initiatives. Resources are also recycled.

Example of Initiative

![]()

Promotion of Energy Conservation and Resource Recycling

![]()

In addition to energy conservation at the steelworks, Kobe Steel also promotes the effective use of resources and maximal recycling during all industrial processes.

Kobe Steel is tireless in its efforts to conserve energy and resources, with initiatives to collect and utilize byproduct gases, implement the best mix of energy use, and find expanded uses for slag, which is the gangue mineral left over after production of steel.

Management

Management

Kakogawa Works Eco-

Commuter Bus

The environmental impact is also reduced in the management departments and offices at plants through full employee participation in environmental initiatives, such as the use of more efficient air conditioning and lighting.

Example of Initiative

![]()

Eco-Commuting at Kakogawa Works Reduces CO2 Emissions

![]()

An eco-commuting program is in place at the Kakogawa Works, which is designed to reduce CO2 emissions through the promotion of public transportation over private cars when commuting to work.

Before implementation of the program, over 8,000 private cars were used by employees in order to commute to work each day. This number was reduced by approximately half, resulting in a cumulative reduction in CO2 emissions of approximately 7,500 tons over the three-year period starting from June 2009.

Product Distribution

Product Distribution

Reduced environmental impact is pursued throughout the distribution chain via comprehensive modal shifts in product transportation from trucks to ships and rail.

Use of shorepower at steelworks.

*Shorepower refers to the process of turning off a ship's engine while it is at berth for loading or other reasons, and supplying electrical power from land instead. This reduces both energy consumption and CO2 emissions.

The Shin Ai Maru, a state-of-the-art domestic shipping vessel

Example of Initiative

![]()

Improved Efficiency in Product Transportation

![]()

Modal shifts are implemented, to the greatest extent possible, when transporting products from the steelworks. Additionally, shipments to nearby locations are combined so as to further increase efficiency.

Additionally, shorepower is provided for ships at berth at Kobe Steel's steelworks and coil centers throughout the country.

Customers

Customers

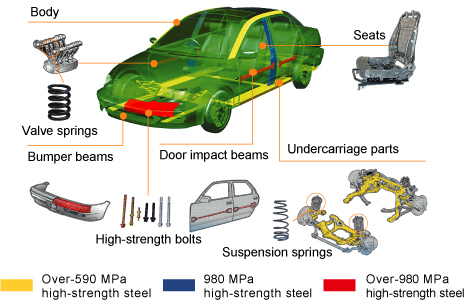

The Iron & Steel Business provides high-strength, highly functional products that help to reduce environmental impact during use.

Example of Initiative

![]()

Reducing CO2 Emissions through Automotive Lightweighting

![]()

Materials that combine both strength with workability can lead to lighter weight automobiles. This results in higher fuel efficiency and reduced CO2 Emissions.

For instance, in the field of steel wire rod and bar, Kobe Steel developed the world's strongest special steels for use in valve springs and bolts. Mass production of these materials led to lighter-weight undercarriage systems and more efficient engines. In sheet products as well, a mass-production system was established for high-strength steel sheet for automotive use, further contributing to the production of lighter cars.

The above are examples of the value chain in place in the Iron & Steel Business, but Kobe Steel contributes to reducing the environmental impact for its customers in other business units as well. For example, Kobe Steel develops products that utilize underused energy sources such as geothermal heat and steam.