DLC coating by UBMS

DLC coating contract processing is our company's specialty.

A new chapter has begun in the history of diamond-like carbon (DLC) film coating. We undertake contract processing for high-performance DLC coating with our UBMS™ series. If you have ever been unsatisfied with conventional DLC film coating and given up using it, please contact us.

Features

DLC film coating with UBMS enables:

- Controlling the hardness of DLC films.

- Achieving high adhesion strength of DLC films.

- Expanding applications of DLC films.

Overview of Our UBMS Series

While DLC films have special properties such as high hardness and low friction coefficient, their applications are limited due to the low adhesion strength of conventional processing.

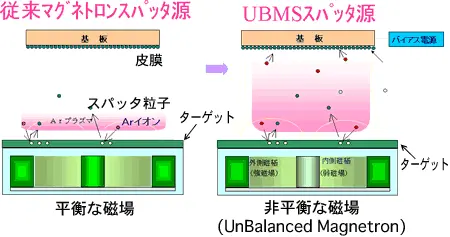

The unbalanced magnetron sputtering (UBMS™) equipment developed by Kobe Steel can produce a well-balanced film with high adhesion strength, expanding the applications of DLC films.

The unbalanced magnetron increases the plasma density near the substrate, intensifying the ion assist effect on the substrate. By controlling the bias voltage applied to the substrate, our UBMS equipment can control the properties of DLC films such as film structure, crystallization properties, composition, adhesion strength, and surface morphology.

Medium-size UBMS for mass production

UBMS504LL

- Effective processing space

Φ450 x H600

- UBM evaporation source

Equipped with 4 sets

Lineup of BELCOAT™ by UBMS

| Name | DLC type |

Thickness (µm) |

Features | Typical applications |

|---|---|---|---|---|

| BELCOAT B | Standard | 0.5–5 | Achieving a balance of wear resistance, lubricity, and adhesion | General mechanical components Dies |

| BELCOAT HB | High hardness | 1–5 | Focused on wear resistance | Automotive components High-load mechanical parts |

| BELCOAT UB | Ultra-high hardness | 1–4 | Focused on wear resistance under high pressure | Automotive components for racing use Cutting tools |

| BELCOAT NB | Nano-multi layer | 1–10 | Achieving a balance of wear resistance, lubricity, and toughness with shock resistance | Bearings and punching dies |

| BELCOAT MB | Metal doped | 1~10 | Properties change by the type and amount of doped metals. Film stress relief effects. |

Automotive components Plastic injection molds |

- *In addition to the above, we can offer a wide variety of DLC coatings to suit your application.

Features of DLC-UBMS™

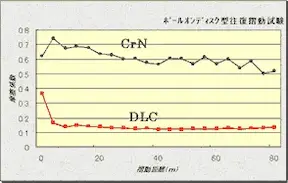

Achieves a DLC film coating with low friction coefficient

The friction coefficient is extremely lower than conventional hard films.

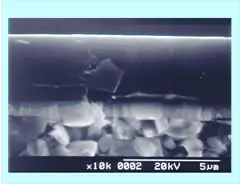

Achieves a DLC coating with high adhesion

Achieves a DLC coating with high adhesion by inserting a metal/C-gradient layer as the intermediate layer.

Typical DLC applications

| Parts |

|

|---|---|

| Dies |

|

| Tools |

|

| Blades |

|

| Other |

|

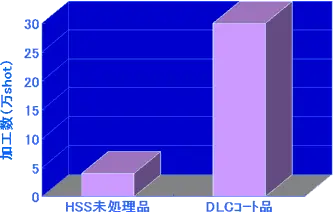

High-speed steel (HSS) for SUS sheet punching

Engine parts for F1 racing cars

Kobe Steel’s high-hardness and high-adhesion DLC coating is applied to formular one engines that are known for incredible specifications with a maximum rotation speed of 19,000 rpms and maximum output of 700 horsepower.

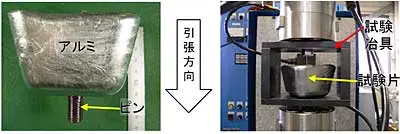

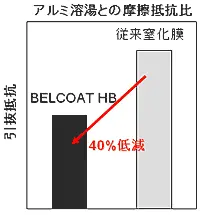

Pins for aluminum die casting

Coating capabilities of UBMS equipment

| Applicable dimensions |

|

|---|---|

| Materials suitable for coating |

Carbide, SUS, tool steel, die steel, aluminum alloy, ceramic, glass

|

| Processing temperature |

150–300℃

|

| Other applicable film types besides DLC |

Nitride coating (TiN, TiAlN, CrN, etc.) Various metal films (W, Nb, etc.) |

| Thickness | 1–10 μm |

Contact Us

You can reach us by clicking the inquiry button.